You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Help!" for: Papercraft or Pepakura

- Thread starter 23Magnum

- Start date

- Status

- Not open for further replies.

Is there an algorithm or equation ?:\ for scaling.

http://www.405th.com/showthread.php/25588-How-to-Scale-Your-Armour-Tutorial-V.2

Or you can guestimate the scale. Build a few low def parts, and you'll quickly get the hang of getting the scale correct.

Ral Partha

Sr Member

For which armor part?Is there an algorithm or equation ?:\ for scaling.

toxictwitcherz

New Member

i need help geting pepakura files i cant figure it out??? please reply

Ral Partha

Sr Member

Make sure that read everything on this reading list. In addition, you can go to the Pepakura and Cardboard Armor forum and look at the sticky called Official Halo Reach Files thread and download the files.i need help geting pepakura files i cant figure it out??? please reply

Hello

I hope this is the right place to ask (if its not MODS please move this to where it should be)

when downloading the MK VI Pepakura files i noticed there are 2 and 3 piece boots. which is better? i imagin the 3 piece boot is easier to fit over a shoe but hard to make?

please anyone that has made a suit can you give me the pros and cons for the boots you made?

cheers

I hope this is the right place to ask (if its not MODS please move this to where it should be)

when downloading the MK VI Pepakura files i noticed there are 2 and 3 piece boots. which is better? i imagin the 3 piece boot is easier to fit over a shoe but hard to make?

please anyone that has made a suit can you give me the pros and cons for the boots you made?

cheers

Evil Jester

New Member

I need to find someone that wouldn't mind unfolding something for me. It is the Rinzler Tron Identity Disc split into two halfs just like in the movie. I just seem to suck at unfolding. Someone please help.

Hello

I hope this is the right place to ask (if its not MODS please move this to where it should be)

when downloading the MK VI Pepakura files i noticed there are 2 and 3 piece boots. which is better? i imagin the 3 piece boot is easier to fit over a shoe but hard to make?

please anyone that has made a suit can you give me the pros and cons for the boots you made?

cheers

You are correct. The 3 piece boot is easier to get over footwear. However, the top and bottom pieces don't always line up, due to warpage during the build state. I think most people go with the 2 piece boot, and then cut the bottoms out so a shoe can go through them.

All,

I admit that I did not read all of the posts in this sticky. If I repeat what everyone knows already I apologize. Here are simple steps that I hope new members find useful.

A lot of people like to use hot glue to stick pieces together. I've been using Elmer's glue and it has work wonders. No burn, no mess. Hopefully you find these simple tutorials useful. I find that using this method speeds up the process.

Here is the goal - an ODST fanny pack.

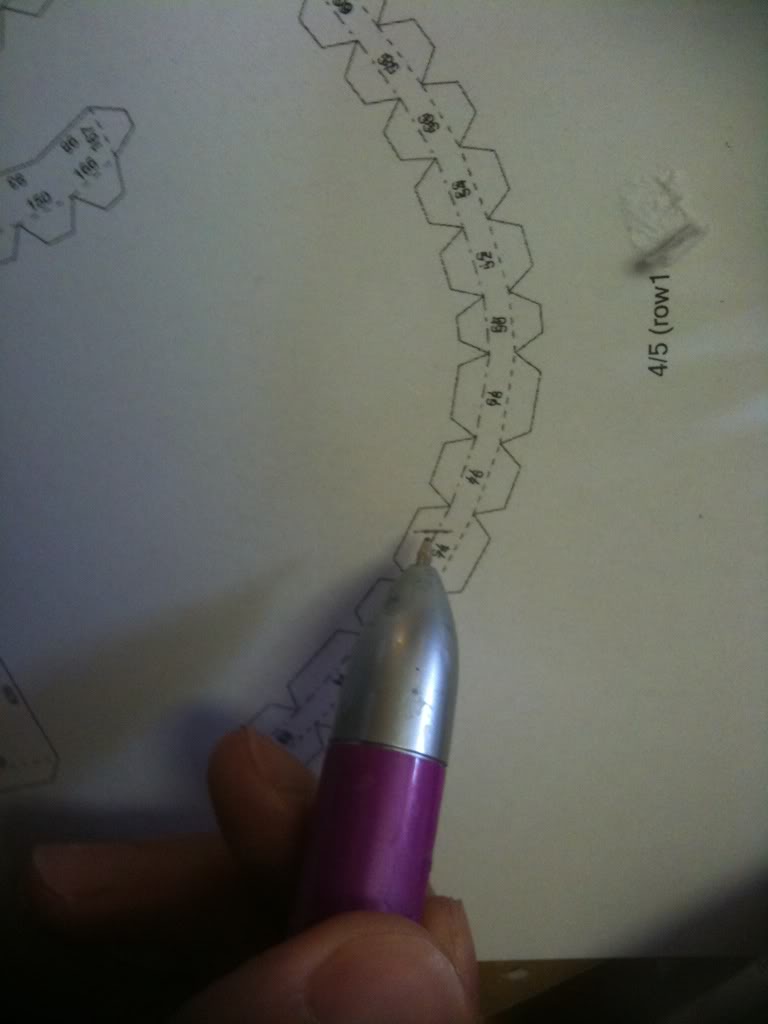

You can use different color to indicate peak or valley fold. Here I cross a line to indicate valley.

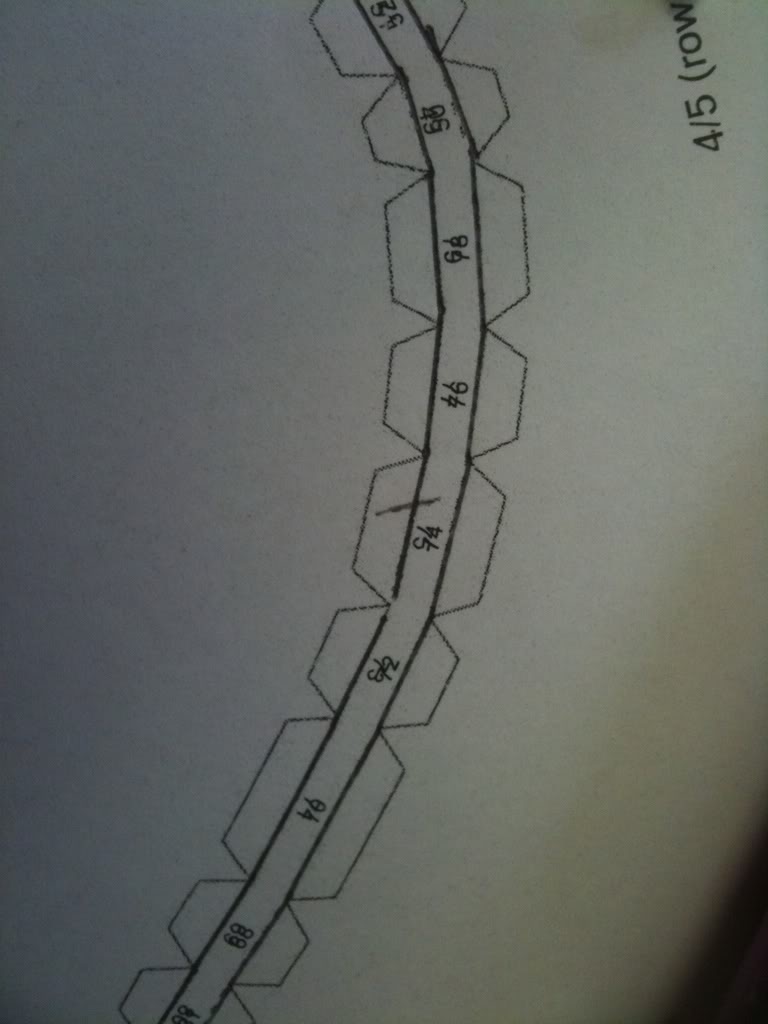

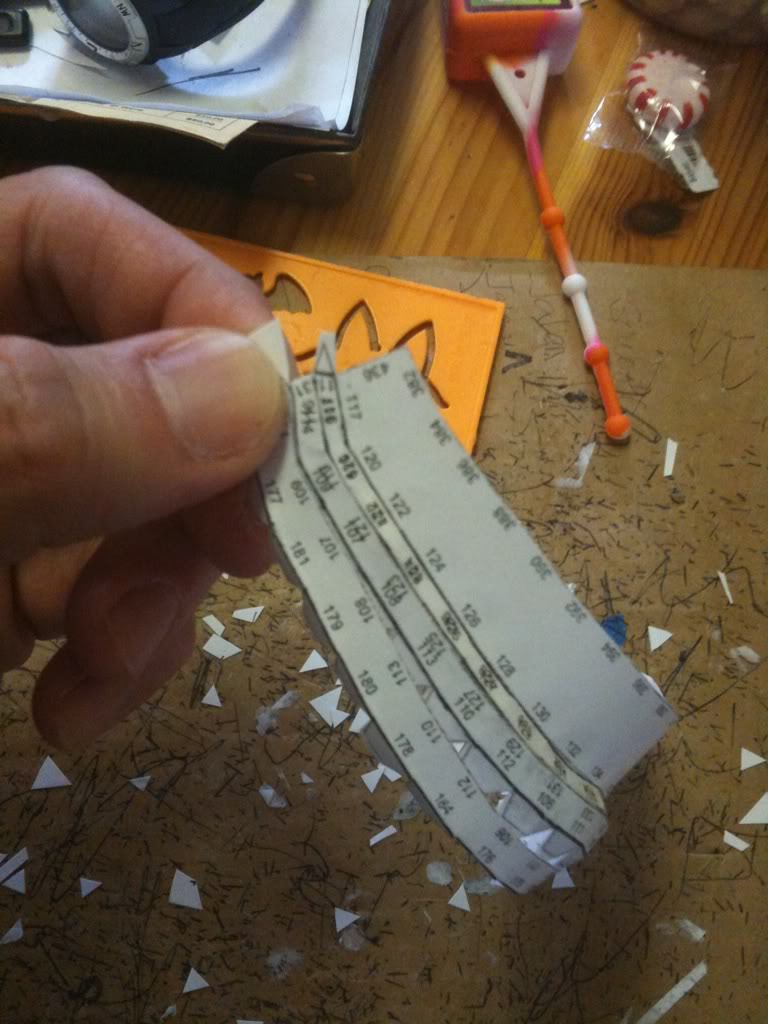

Next I draw lines before cutting.

I fold the line before cutting.

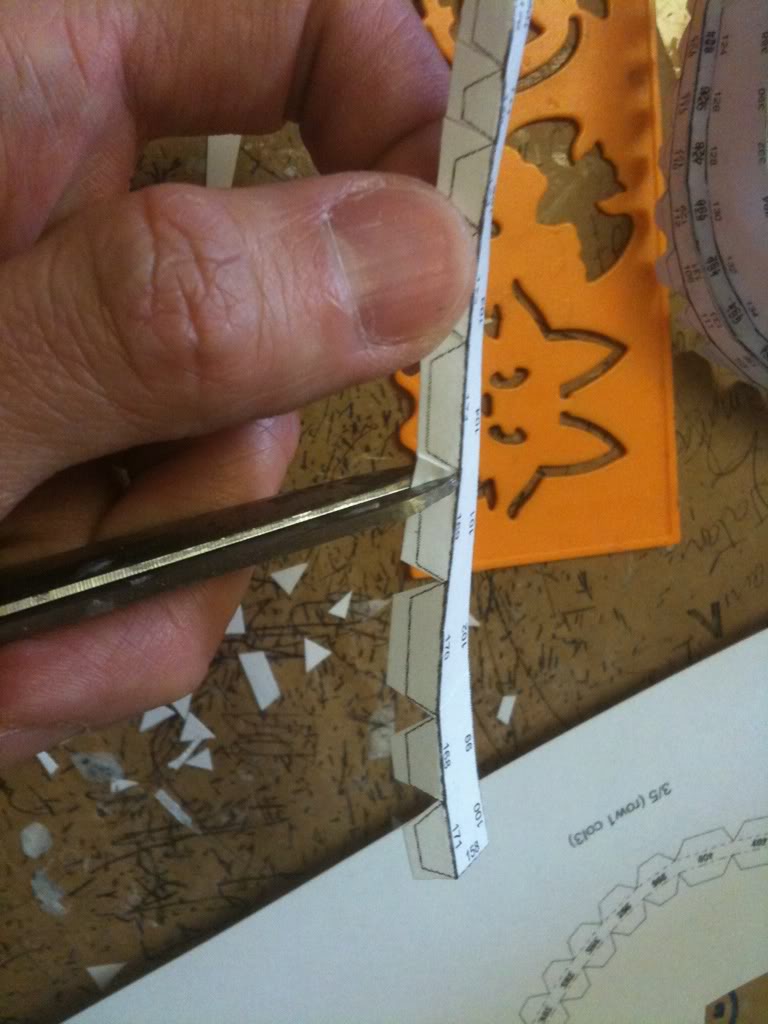

I cut out the piece. I did not cut precisely on the tabs because they will not be visible after gluing.

I apply glue on both faces that will stick together.

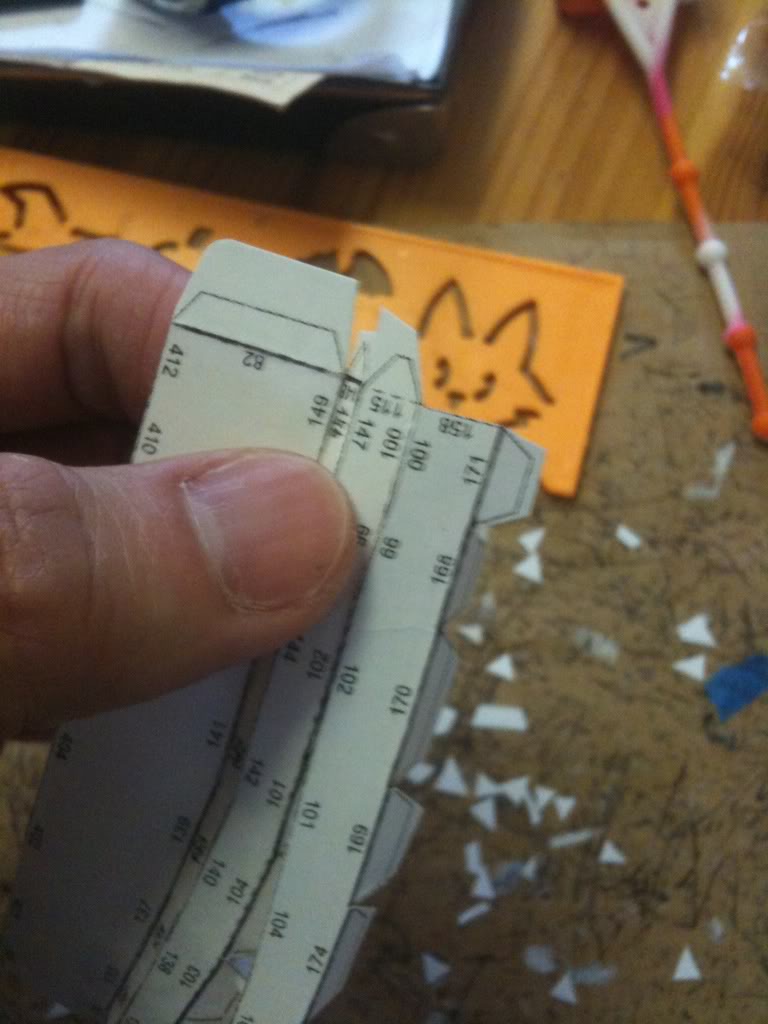

You need to wait at lead 10-15 seconds for the glue become tacky. During this time you can start cutting other pieces. After that press one end together.

Stick the other end.

Finally, because it is white glue, you still have to finally adjust the middle part.

The final pep file is as strong as using hot glue. After resin, glassing or rondo, it looks just as good. Try it.

I admit that I did not read all of the posts in this sticky. If I repeat what everyone knows already I apologize. Here are simple steps that I hope new members find useful.

A lot of people like to use hot glue to stick pieces together. I've been using Elmer's glue and it has work wonders. No burn, no mess. Hopefully you find these simple tutorials useful. I find that using this method speeds up the process.

Here is the goal - an ODST fanny pack.

You can use different color to indicate peak or valley fold. Here I cross a line to indicate valley.

Next I draw lines before cutting.

I fold the line before cutting.

I cut out the piece. I did not cut precisely on the tabs because they will not be visible after gluing.

I apply glue on both faces that will stick together.

You need to wait at lead 10-15 seconds for the glue become tacky. During this time you can start cutting other pieces. After that press one end together.

Stick the other end.

Finally, because it is white glue, you still have to finally adjust the middle part.

The final pep file is as strong as using hot glue. After resin, glassing or rondo, it looks just as good. Try it.

AvAngelAvA

New Member

Scaling Advice?

Hey everyone I've been working on my Kat pepakura armor project for awhile now (sadly had to take a pretty long break) and was just looking for some advice on my measurements before printing.. I've finished two boot toes and the handplates now, so I'm fairly comfortable with the pepping process and would really like to jump into a piece a bit more intensive.. so I found L3X BLU3R1V3R's female reach torso here: http://www.405th.com/showthread.php/28565-Another-Reach-Mark-V-Torso. I've read many comments about it and it seems to be the best Reach torso out there

I've been working on my Kat pepakura armor project for awhile now (sadly had to take a pretty long break) and was just looking for some advice on my measurements before printing.. I've finished two boot toes and the handplates now, so I'm fairly comfortable with the pepping process and would really like to jump into a piece a bit more intensive.. so I found L3X BLU3R1V3R's female reach torso here: http://www.405th.com/showthread.php/28565-Another-Reach-Mark-V-Torso. I've read many comments about it and it seems to be the best Reach torso out there  I've scaled it to what I thought was accurate, but because its 44 pages of cardstock I couldn't in good conscience print it all out without being 99% sure that it would end up fitting correctly after pepping, fiberglassing, and the whole shebang.

I've scaled it to what I thought was accurate, but because its 44 pages of cardstock I couldn't in good conscience print it all out without being 99% sure that it would end up fitting correctly after pepping, fiberglassing, and the whole shebang.

I used a formula (by Ral Partha) provided on the page with the chest piece to find my current scale: Assembled Height (in mm) = 10.4 x (shoulder width in cm). My shoulder width in cm is 49.5 x 10.4 = 514.8mm

SO. Here's the scaling its set at right now, height: 515mm; width: 457mm; depth: 517mm

My height is 5'10" and my measurements are (estimating beginning and ending of measurements from legendary statue and the pep file itself), shoulder width: 495mm; width across ribs: 406mm; chestplate (top-bottom of ribcage): 267mm; base of neck to mid-back: 317mm... yeah I'm probably being way too particular about this but I'd really rather not waste all that paper and time spent cutting out and gluing so I thought it'd be better to provide more info than needed than not enough.

so I thought it'd be better to provide more info than needed than not enough.

As you can see the width of my shoulders and the width provided in the pep file are not matching up. So, am I measuring in a wrong place compared to the file? Do I scrap the formula (which was said to be accurate by others who used it) and just go by width - width? Do I just take what I have now and go with it? ..or am I just doing everything wrong? lol

I also don't quite know how much more I should add to the measurements to compensate for shrinking during the fiberglass/resin process... any advice there?

I realize this is one of the most common requests/questions out there and I'm sorry for adding another one to the masses, but it seems like every case is different and because it's basically the biggest piece in the build I really want to be sure... (or as sure as one can be about these things..)

Thanks for your patience,

Angela

*edit: that formula is for the male version of this torso also made by L3X BLU3R1V3R. Maybe that's part of the discrepancies? The female torso is edited to be a bit smaller/thinner.*

Hey everyone

I used a formula (by Ral Partha) provided on the page with the chest piece to find my current scale: Assembled Height (in mm) = 10.4 x (shoulder width in cm). My shoulder width in cm is 49.5 x 10.4 = 514.8mm

SO. Here's the scaling its set at right now, height: 515mm; width: 457mm; depth: 517mm

My height is 5'10" and my measurements are (estimating beginning and ending of measurements from legendary statue and the pep file itself), shoulder width: 495mm; width across ribs: 406mm; chestplate (top-bottom of ribcage): 267mm; base of neck to mid-back: 317mm... yeah I'm probably being way too particular about this but I'd really rather not waste all that paper and time spent cutting out and gluing

As you can see the width of my shoulders and the width provided in the pep file are not matching up. So, am I measuring in a wrong place compared to the file? Do I scrap the formula (which was said to be accurate by others who used it) and just go by width - width? Do I just take what I have now and go with it? ..or am I just doing everything wrong? lol

I also don't quite know how much more I should add to the measurements to compensate for shrinking during the fiberglass/resin process... any advice there?

I realize this is one of the most common requests/questions out there and I'm sorry for adding another one to the masses, but it seems like every case is different and because it's basically the biggest piece in the build I really want to be sure... (or as sure as one can be about these things..)

Thanks for your patience,

Angela

*edit: that formula is for the male version of this torso also made by L3X BLU3R1V3R. Maybe that's part of the discrepancies? The female torso is edited to be a bit smaller/thinner.*

Ral Partha

Sr Member

Uh, yeah. Sorry about that. I should have been more specific about that formula.*edit: that formula is for the male version of this torso also made by L3X BLU3R1V3R. Maybe that's part of the discrepancies? The female torso is edited to be a bit smaller/thinner.*

Give me an hour and I'll come up with a formula for the L3X female torso model.

EDIT:

Okay, here's the scaling formula for L3X's Reach female torso:

Just like in the male torso, use a pic of Noble-6 and measure the distance between your shoulders in centimeters and plug it in the formula above.Assembled Height (in mm) = 11.41 x (Shoulder Width in cm) +1mm

AvAngelAvA

New Member

Thanks so much Ral Partha!!! I seriously appreciate it  very excited to be back in business on this build.

very excited to be back in business on this build.

Talon Karrde

New Member

I have looked everywhere for this answer, but I could not find one. What printer type is everyone using?

Both of my printers can only handle 65 lb card stock. I would like to use 110lb instead.

Both of my printers can only handle 65 lb card stock. I would like to use 110lb instead.

Ral Partha

Sr Member

From my experience, HP printers can handle 110# cardstock. So if you're in the market for a printer, go for an HP.I have looked everywhere for this answer, but I could not find one. What printer type is everyone using?

Both of my printers can only handle 65 lb card stock. I would like to use 110lb instead.

I have looked everywhere for this answer, but I could not find one. What printer type is everyone using?

Both of my printers can only handle 65 lb card stock. I would like to use 110lb instead.

Get a photo printer. They're supposed to print on heavy paper.

There is also some room between what the specs say and what makes the printer catch fire. For example, I have an HP Photosmart 4180 that, according to specs, can take 10x15 cm photo paper up to 236 g/m² and "cards" (whatever HP means by that) up to 200 g/m², but paper only up to 90 g/m². And yet it prints on 250 g/m² without problems.

Evil Jester

New Member

I have looked everywhere for this answer, but I could not find one. What printer type is everyone using?

Both of my printers can only handle 65 lb card stock. I would like to use 110lb instead.

If worst comes to worst, spray adhesive a basic piece of paper to the card stock. I had to so that until I got an HP. Works in a pinch.

Talon Karrde

New Member

Thanks to all of you for the help. I have 2 HP printers and didn't want to wreck one trying to print on heavy cardstock. Now I know that its safe to print that weight paper, I can finally start my ODST build.

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 2,342