Zat German

Member

After about a month of being busy with work and personal things as well as doing research into various materials and tools, I finally started my Reach armor build. I really wanted to build a Mark VI suit first but it is much more complicated to build out of foam than Mark V. So I decided to cut my teeth on the Reach armor and then maybe make some Halo 3 stuff.

My primary build material are EVA foam mats from Harbor Freight. You can also get these mats at Walmart as a Gold's Gym brand and Big Lots. The Walmart and Big Lots versions have diamond plat rather than the houndstooth-like pattern of Harbor Freight's. When on sale, Harbor Freight's mats are the cheapest I have found, with Big Lots being cheaper off sale. You can also get these mats in various colors online but all the sellers I have found so far really gouge you on shipping.

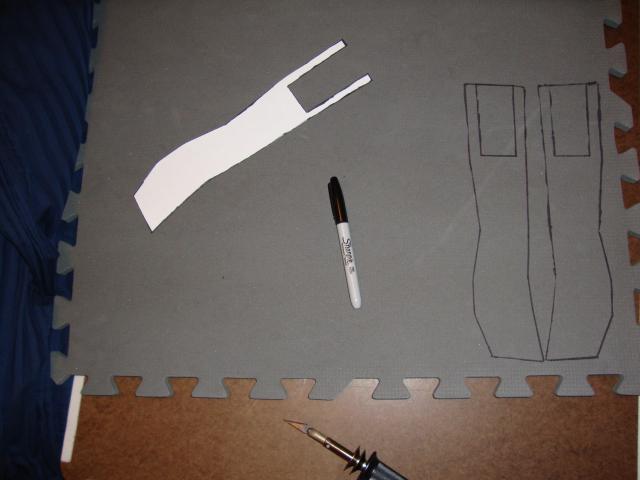

Here is a shot of the first pieces I cut out. I started out using a hot knife(shown at the bottom of the picture) but after remembering that I have a mini-jigsaw, I started using that exclusively. It works great. It does produce edges that will need more cleanup but it is super fast to cut with. You can see a picture of it in the tools section at the end of the post.

Here are the patterns I initially cut out from the Pepakura file. I am using lganderson's version since it is the most accurate one available to-date. L3X's would be nice to have but it is still in the process of being unfolded and is not available.

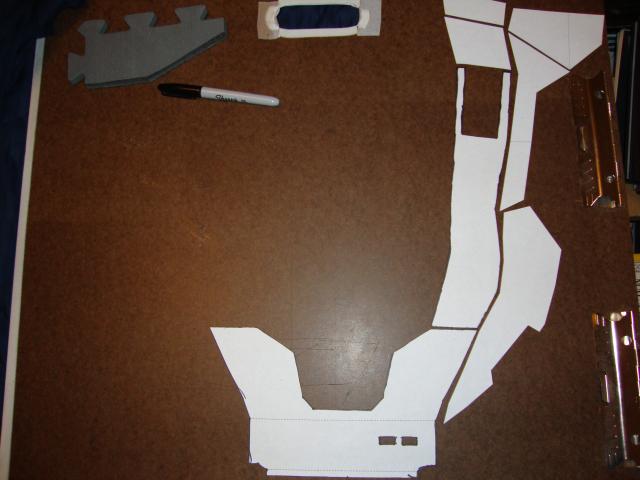

My assembly progress so far, as of this post today.

Here is a picture of the underside of the armor. I used the electric knife to cut out these angles but as you can see I cut out way too much. It is okay though, because another layer of foam will cover all of this up. I may try filling it in with some Foam Coat+Bounce, to see how well that works as a gap filler.

On the top side of the armor, you get all these gaps here where the hot glue did not reach. I do not feel like cleaning off a ton of hot glue, so I am using just enough to join pieces without it squishing through the top, if possible. You can fix these gaps quite easily though thanks to a tip from a friend.

The tip: Use superglue gel! Just put a little in the gap and squeeze the two parts together for about 30 seconds. After that, the gel will hold the two parts close together. The excess that squeezes out can be wiped off. Wear latex gloves unless you like superglue all over your fingers.

Same gap after it has been glued with the gel.

Tools Section

This part of the post will be kept up-to-date with all of the tools I have used for the build. I figure this may be a useful reference to anyone getting started with foam.

My primary build material are EVA foam mats from Harbor Freight. You can also get these mats at Walmart as a Gold's Gym brand and Big Lots. The Walmart and Big Lots versions have diamond plat rather than the houndstooth-like pattern of Harbor Freight's. When on sale, Harbor Freight's mats are the cheapest I have found, with Big Lots being cheaper off sale. You can also get these mats in various colors online but all the sellers I have found so far really gouge you on shipping.

Here is a shot of the first pieces I cut out. I started out using a hot knife(shown at the bottom of the picture) but after remembering that I have a mini-jigsaw, I started using that exclusively. It works great. It does produce edges that will need more cleanup but it is super fast to cut with. You can see a picture of it in the tools section at the end of the post.

Here are the patterns I initially cut out from the Pepakura file. I am using lganderson's version since it is the most accurate one available to-date. L3X's would be nice to have but it is still in the process of being unfolded and is not available.

My assembly progress so far, as of this post today.

Here is a picture of the underside of the armor. I used the electric knife to cut out these angles but as you can see I cut out way too much. It is okay though, because another layer of foam will cover all of this up. I may try filling it in with some Foam Coat+Bounce, to see how well that works as a gap filler.

On the top side of the armor, you get all these gaps here where the hot glue did not reach. I do not feel like cleaning off a ton of hot glue, so I am using just enough to join pieces without it squishing through the top, if possible. You can fix these gaps quite easily though thanks to a tip from a friend.

The tip: Use superglue gel! Just put a little in the gap and squeeze the two parts together for about 30 seconds. After that, the gel will hold the two parts close together. The excess that squeezes out can be wiped off. Wear latex gloves unless you like superglue all over your fingers.

Same gap after it has been glued with the gel.

Tools Section

This part of the post will be kept up-to-date with all of the tools I have used for the build. I figure this may be a useful reference to anyone getting started with foam.

- Proxxon Jigsaw: For cutting out patterns

- Electric Knife: For making miter cuts

- Hot Glue Gun: For gluing parts together

- Hair Dryer: For shaping the foam, hands friendlier than heat gun

- Superglue Gel: For closing up gaps

Attachments

-

DSC00360.jpg43.3 KB · Views: 418

DSC00360.jpg43.3 KB · Views: 418 -

DSC00363.jpg51.6 KB · Views: 424

DSC00363.jpg51.6 KB · Views: 424 -

DSC00365.jpg52.4 KB · Views: 451

DSC00365.jpg52.4 KB · Views: 451 -

DSC00367.jpg83.9 KB · Views: 392

DSC00367.jpg83.9 KB · Views: 392 -

DSC00368.jpg63.5 KB · Views: 399

DSC00368.jpg63.5 KB · Views: 399 -

electric_knife.jpg19.4 KB · Views: 385

electric_knife.jpg19.4 KB · Views: 385 -

proxxon_jigsaw.jpg27.3 KB · Views: 395

proxxon_jigsaw.jpg27.3 KB · Views: 395 -

DSC00372.jpg64.8 KB · Views: 440

DSC00372.jpg64.8 KB · Views: 440 -

DSC00369.jpg63.7 KB · Views: 411

DSC00369.jpg63.7 KB · Views: 411 -

superglue_gel.jpg23.4 KB · Views: 375

superglue_gel.jpg23.4 KB · Views: 375 -

hair_dryer.jpg23.8 KB · Views: 391

hair_dryer.jpg23.8 KB · Views: 391 -

hot_glue_gun.jpg20.4 KB · Views: 403

hot_glue_gun.jpg20.4 KB · Views: 403