Spitfire22V

Well-Known Member

Thanks for the comments guys! Glad you are enjoying the updates as much as I enjoy posting them!

Speaking of which, I've got another for you.

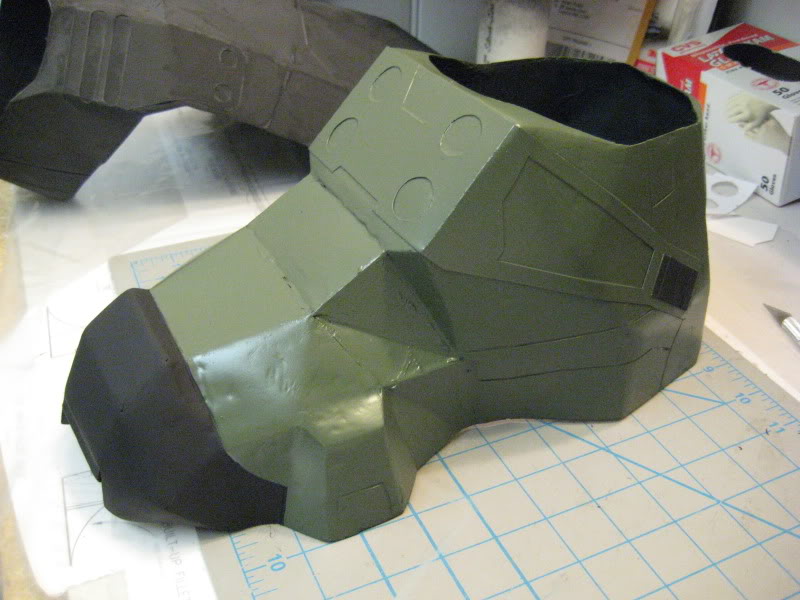

I finished the boots except for padding, strapping, and connecting the toe and heel parts.

Sprayed the final olive drab coat, then masked off and painted the black toe part and the side buckles. Also painted the very tip of toes (the wood "steps" I made earlier) silver.

Again, I nervously hacked into a finished piece and cut out the middle section.

Next, I black washed the pieces, and also used a dark tan (Earth tone) paint to wash the bottom of the boots to dirty them up some more. They ARE boots for a soldier's battle suit after all!

Finally, did the dry-brush scratches and clear coated them. Again, I think either I did a little too much dry-brushing, or my technique sucks because I'm not 100% satisfied with the look. It doesn't look enough like natural scratches on a metal surface; if you look closely it's rather painfully obvious that it's painted on. Oh well.

Here are the finished boots. (The connector tubing is not attached in these photos).

Now for attaching the tubing to connect the boots....

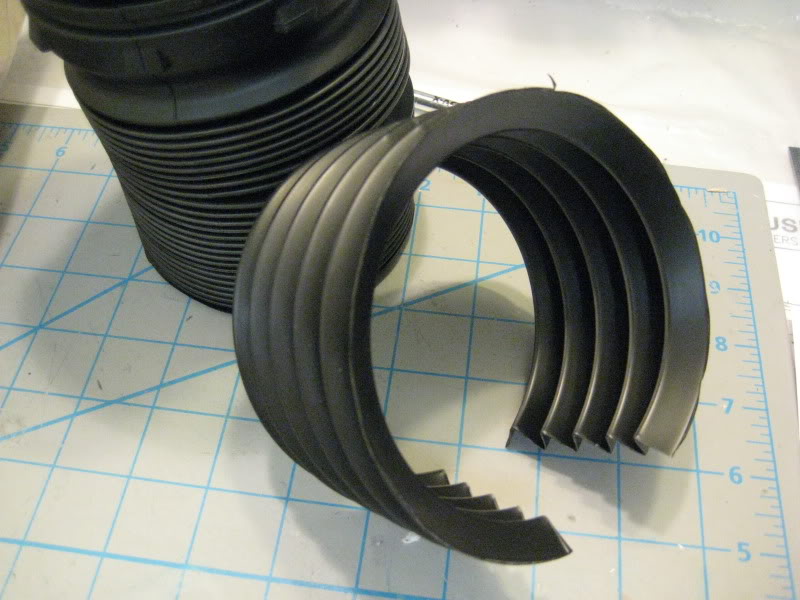

From Hickeydog's build thread, I used his idea of flexible drainage pipe for the boot connector tubing and picked up the same exact thing he bought. For about $6-$7, you get ~22 inches of piping, which is more than enough. It is a 4 inch diameter tube, which is a little small. A 5 inch tube would probably be perfect.

I cut out a section, and then split into two and trimmed it to the size I needed.

THIS THE PART WHERE I NEED HELP OR SUGGESTIONS.

I tried gluing the tubing to the boots using epoxy, the strongest glue I know of that could work in this situation. However, even with properly scratching up the gluing surfaces to promote adhesion, the epoxy does not stick to the plastic tubing. The tubing just keeps popping off. Any attachment ideas are greatly appreciated. At the moment, I'm considering using hot glue, screws, or even better: a combination of the two. I really want this connection to be strong to not have to boots come undone if I'm out and about.

DOES NOT WORK!

Thanks in advance for any help you can provide, and thanks for stopping by!

Speaking of which, I've got another for you.

I finished the boots except for padding, strapping, and connecting the toe and heel parts.

Sprayed the final olive drab coat, then masked off and painted the black toe part and the side buckles. Also painted the very tip of toes (the wood "steps" I made earlier) silver.

Again, I nervously hacked into a finished piece and cut out the middle section.

Next, I black washed the pieces, and also used a dark tan (Earth tone) paint to wash the bottom of the boots to dirty them up some more. They ARE boots for a soldier's battle suit after all!

Finally, did the dry-brush scratches and clear coated them. Again, I think either I did a little too much dry-brushing, or my technique sucks because I'm not 100% satisfied with the look. It doesn't look enough like natural scratches on a metal surface; if you look closely it's rather painfully obvious that it's painted on. Oh well.

Here are the finished boots. (The connector tubing is not attached in these photos).

Now for attaching the tubing to connect the boots....

From Hickeydog's build thread, I used his idea of flexible drainage pipe for the boot connector tubing and picked up the same exact thing he bought. For about $6-$7, you get ~22 inches of piping, which is more than enough. It is a 4 inch diameter tube, which is a little small. A 5 inch tube would probably be perfect.

I cut out a section, and then split into two and trimmed it to the size I needed.

THIS THE PART WHERE I NEED HELP OR SUGGESTIONS.

I tried gluing the tubing to the boots using epoxy, the strongest glue I know of that could work in this situation. However, even with properly scratching up the gluing surfaces to promote adhesion, the epoxy does not stick to the plastic tubing. The tubing just keeps popping off. Any attachment ideas are greatly appreciated. At the moment, I'm considering using hot glue, screws, or even better: a combination of the two. I really want this connection to be strong to not have to boots come undone if I'm out and about.

DOES NOT WORK!

Thanks in advance for any help you can provide, and thanks for stopping by!