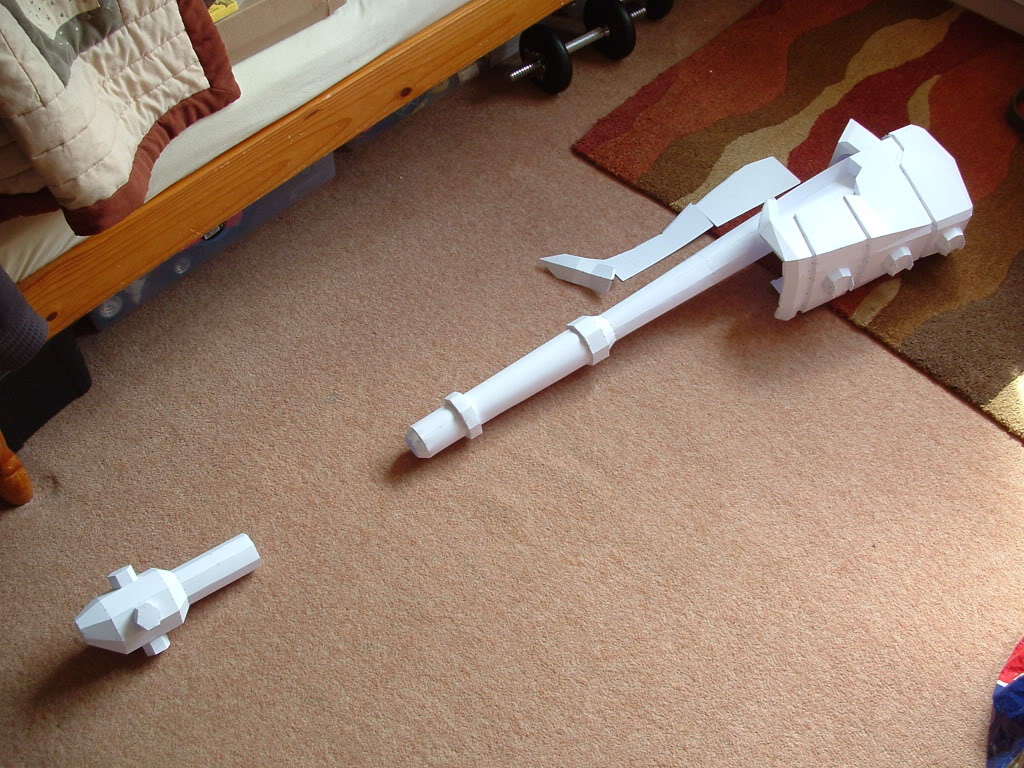

Gravity Hammer (Completed!)

I'm taking a bit of a break form armour making: I work at such a slow pace that it'd be better to finish some sort of weapon in time for a midnight game launch, or similar event, rather than risk a mostly completed armour set.

Here is a picture of the hammer so far:

I'm taking a bit of a break form armour making: I work at such a slow pace that it'd be better to finish some sort of weapon in time for a midnight game launch, or similar event, rather than risk a mostly completed armour set.

Here is a picture of the hammer so far: