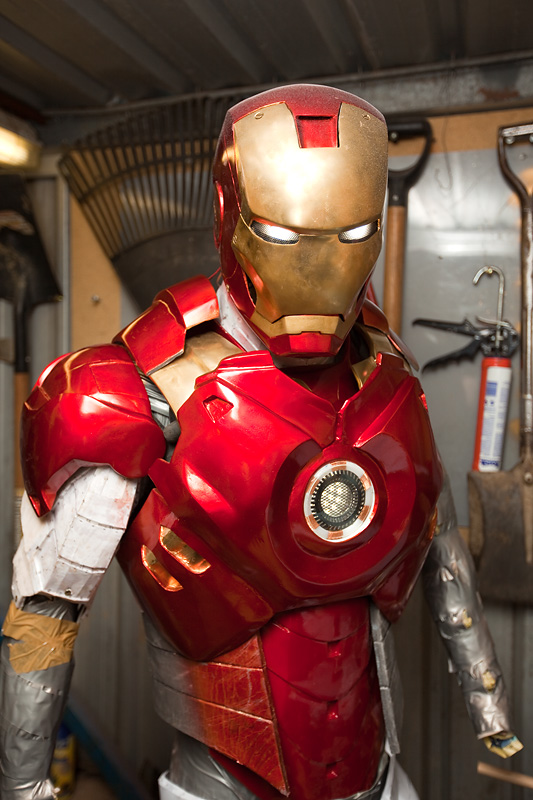

*******Updated EDIT: I have now finished my THIRD Iron Man suit, constructed in FULL STEEL.

*******Updated EDIT: I'm now onto my THIRD Iron Man suit which has been the goal to eventually build in metal.

The first half-finished wearable suit was pepakura and fibreglass/bondo.

The second completely finished suit was all cardboard as a trial-fit for a metal build.

I am now progressing very well with a FULL STEEL SUIT. Go to the last page for current updates.*****

First suit fibreglass bondo

Second suit cardboard

Current suit steel

In the meantime, back in the beginning..... read on.

Not sure if I will do the whole suit yet. This is my first helmet and i am enjoying the heck out of it. Currently I am building an observatory in my front yard, but when I run out steel, I move into the shed and continue with the helmet.

I have made a few mistakes in the folding and gluing, but I didn't know about the lines that represent hill and valley folds, nor did I know you could switch on the numbers and have them print out on the cutouts, until AFTER I had guessed it all. In any case, this one will be good practice. If I stuff it up, I am sure I will learn heaps in the process!

That considered, I think I did pretty well and I know that the bondo (car-body filler of any kind really?) will hide all manner of sin in the shaping process. This is Australia and I haven't checked if Bondo exists here or if we have an equivalent. I'm sure we do.

If all goes well, then we will see if I move onto the rest of the suit.

Here's where I'm at so far. I used 200GSM card stock to print on. Glued all together with superglue. What a God-send that stuff is!

The shuttle you see in the pictures was done with normal A4 printer paper and PVA wood glue. What a pain in the butt that was, holding paper together and waiting for each bit to dry.

The helmet now has two coats of resin on the outside. Ready to lay fibreglass on the inside.

Baz.

View attachment 168813

View attachment 168814

View attachment 168815

View attachment 168816

*******Updated EDIT: I'm now onto my THIRD Iron Man suit which has been the goal to eventually build in metal.

The first half-finished wearable suit was pepakura and fibreglass/bondo.

The second completely finished suit was all cardboard as a trial-fit for a metal build.

I am now progressing very well with a FULL STEEL SUIT. Go to the last page for current updates.*****

First suit fibreglass bondo

Second suit cardboard

Current suit steel

In the meantime, back in the beginning..... read on.

Not sure if I will do the whole suit yet. This is my first helmet and i am enjoying the heck out of it. Currently I am building an observatory in my front yard, but when I run out steel, I move into the shed and continue with the helmet.

I have made a few mistakes in the folding and gluing, but I didn't know about the lines that represent hill and valley folds, nor did I know you could switch on the numbers and have them print out on the cutouts, until AFTER I had guessed it all. In any case, this one will be good practice. If I stuff it up, I am sure I will learn heaps in the process!

That considered, I think I did pretty well and I know that the bondo (car-body filler of any kind really?) will hide all manner of sin in the shaping process. This is Australia and I haven't checked if Bondo exists here or if we have an equivalent. I'm sure we do.

If all goes well, then we will see if I move onto the rest of the suit.

Here's where I'm at so far. I used 200GSM card stock to print on. Glued all together with superglue. What a God-send that stuff is!

The shuttle you see in the pictures was done with normal A4 printer paper and PVA wood glue. What a pain in the butt that was, holding paper together and waiting for each bit to dry.

The helmet now has two coats of resin on the outside. Ready to lay fibreglass on the inside.

Baz.

View attachment 168813

View attachment 168814

View attachment 168815

View attachment 168816

Last edited: