Something I have been wanting to do for the past few weeks was to make the Cortana data chip seen in the Halo 5 trailer. I based it off of the reference shots as best as I could.

Here is the only decent reference shot out there.

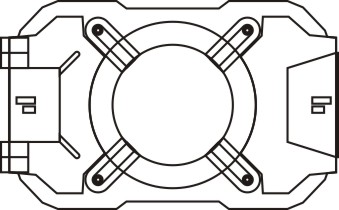

Here is my computer drawing.

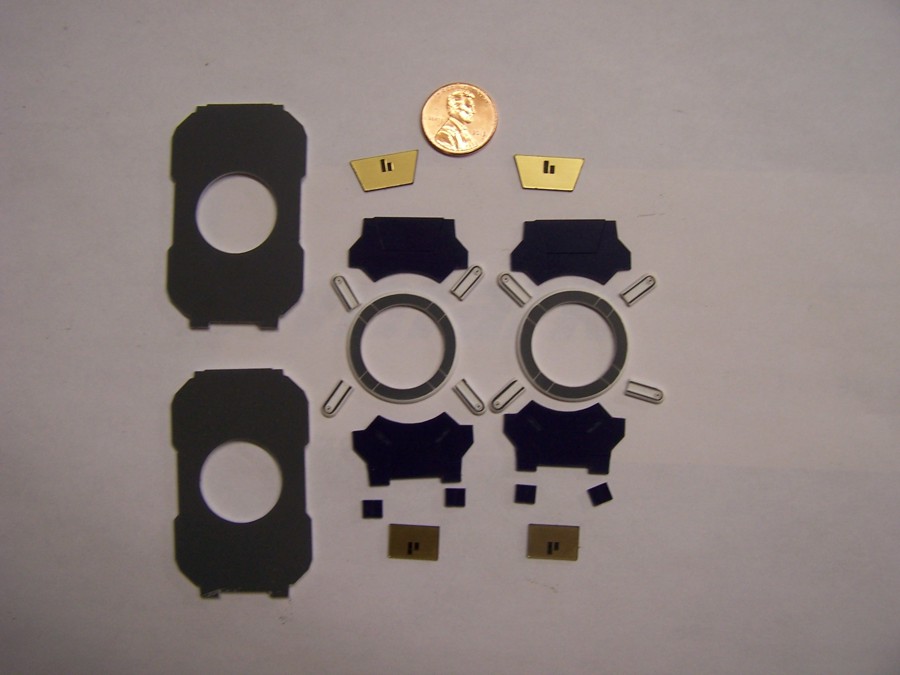

I did a test cut out to see if the size was good, and it seemed to be pretty dead on.

Then I modified the files to work with my laser cutter. I cut out all of the parts using various thickness of plastic.

Then all I had to do was glue the pieces together.

Then I did some minor sanding and primed it.

I also did a clear coat, but I will let it dry overnight before the molding begins.

Thanks for looking.

Here is the only decent reference shot out there.

Here is my computer drawing.

I did a test cut out to see if the size was good, and it seemed to be pretty dead on.

Then I modified the files to work with my laser cutter. I cut out all of the parts using various thickness of plastic.

Then all I had to do was glue the pieces together.

Then I did some minor sanding and primed it.

I also did a clear coat, but I will let it dry overnight before the molding begins.

Thanks for looking.