Better late than never, right?

It took me long enough, but I've finally finished working on an Assault Rifle cast I got from Justinian almost a year ago.

The casting I received from him was near flawless- I had barley any filling and sanding that needed to be done which was great. I requested one of his hollow castings as I wanted to put electronics inside of it.

For electronics I wanted to include a display counter and if possible a sound system. Due to the size and profile of the AR I figured I wouldn't be able to put in a very large speaker, but still I really wanted to see if it was just possible to do, period.

Justin made his AR kit into modular parts, and they fit together like a glove after a little sanding. The only other work that needed done to the raw parts was drilling the hole for the barrel and the flashlight, and the holes for the wires so they’d have a conduit to run through.

Once I had the body work done (which hardly took any time, like I said, Justin really outdid himself with this) I began to play with how the pieces would fit together. I knew that once they were together I would have a hard time painting the seam and trying to get painters tape into some the finer areas would be a pain, so I went ahead and primed them and then gave them their main base coat for color.

The colors I used for this project were

-Krylon flat Black (lower receiver/grip)

-Krylon Satin Nickel (middle section)

-Rustoleum Dark Steel (upper receiver)

After they had a couple layers of their main colors painted, I started the assembly process. I decided to use JB Weld (a simple 2pt epoxy) to hold the pieces together. TO make this easier, I took my dremel and carved a channel in each piece on the joining surface and also scuffed up the surface to promote better adhesion. It also helped with keeping any spill over minimal when the pieces were pressed together.

After a day of waiting for the epoxy cure, I drilled the hole for the barrel and flashlight. Then it was time for the really fun part- the electronics.

My go-to for this part of the project is 405th regular thatdecade. First, I gotta tell you that he was a pleasure to work with through this whole project. Whenever I had a question (no matter how simple) he was able to answer it or help me work out a solution. There were also a couple of times I ran into somewhat large setbacks and he was able to help me out. He's probably as happy as I am this is done so he doesn't have to deal with me anymore

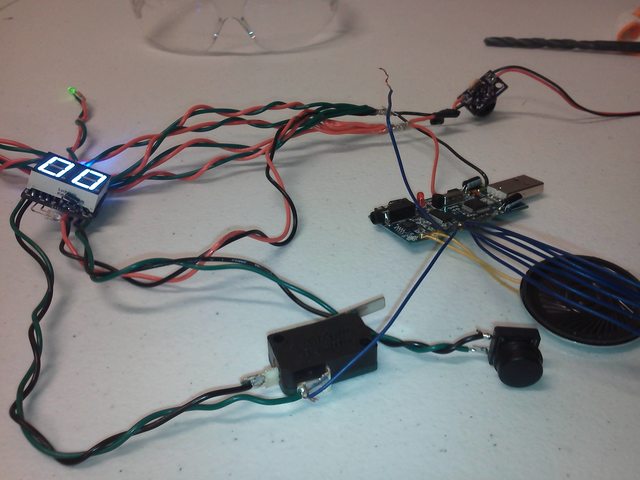

After I reached out to thatdecade and told him what I was planning to do, he was able to hook me up with a prototype for his new ammo counter display kits. The kit itself is pretty frickin cool- it has a trigger switch, a counter reset switch and an illuminated power switch. This is all ran off a standard 3 AAA battery pack.

When powered on, the counter starts at 32. When the trigger is pulled and held or pulsed the counter depletes to zero and can be reset by pushing the reset button. From there the cycle begins again.

If you've got an Assault Rifle, Battle Rifle or DMR prop I HIGHLY recommend one of his kits to take your prop to the next level. Speaking of the next level, the next thing I wanted to do with the kit was add sound.

Since this was more of an experiment for me I didn't want to spend too much money on a sound kit. It also would be required to run off the battery pack for the display counter so I didn't have a lot of options to work with. In the end, I decided to go with an inexpensive kit from http://www.electronics123.com/ for about $20. This kit has one small speaker that while not the loudest, would serve this purpose and also ran off a 3 AAA battery pack.

After getting the software for the board so I could program it I began feeding it sound files. I decided to use the Halo 4 assault rifle sounds because it sounds so meaty and since I had one small speaker I wanted to sound a ferocious as it could .

.

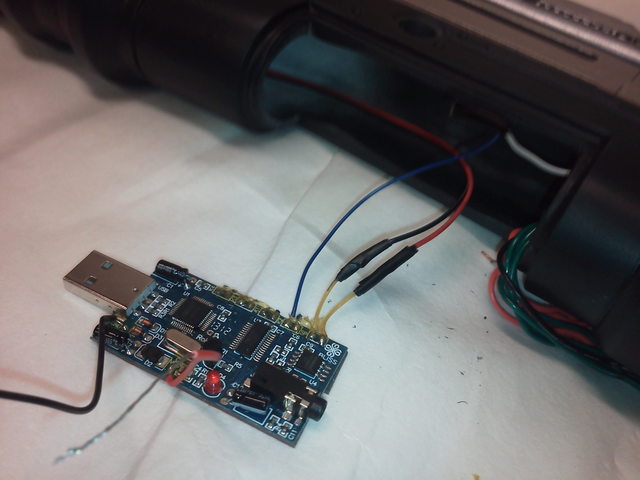

Once I was satisfied with the sounds, I began to tackle how to integrate the sound board with the ammo counter board. I removed the battery pack from the sound board and then wired the board into the counters power source. Okay, so the boards both had power and could be turned on by the switch, so that was good. The next task was figuring out how to get the sound to play when the trigger was pulled. I figured out pretty early that I would just need to take the signal wire from the sound board and connect it to the trigger. When I did that, and pulled the trigger the sound loop would play but the counter would not do anything….hmmm. I knew I must be missing something simple but for the life of me I could NOT figure out what it was. I was starting to get frustrated so I consulted thatdecade to see what he thought and he informed me that I forgot the ground wire on the sound board (d’oh!).

So after a little rewiring, that ended up being exactly what the problem was. Now when the trigger was pulled the sound would play with it. Here is a sample of it during the testing phase (I apologize for the cell phone quality recording; it sounds much better in person).

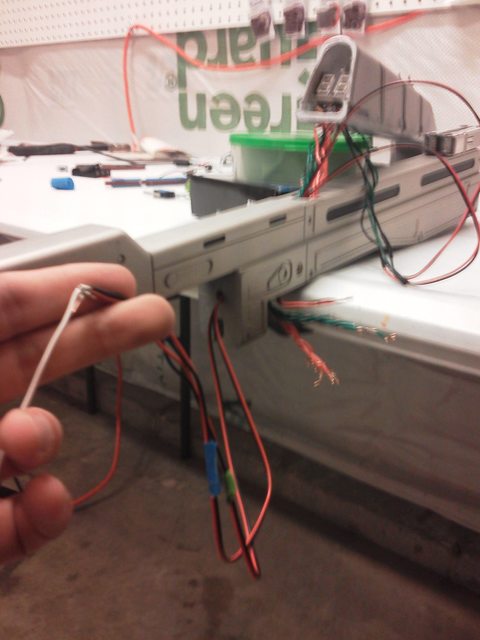

Now that I had the wiring down it was time to start inserting the electronics into the AR cast. Fortunately, the holes I drilled earlier were large enough that they made feeding the wires pretty easy.

The sound board and battery pack would be installed into the AR’s fore grip section, and would be accessed by a removable section that stays held in place with magnets. To keep the battery pack and sound board from rattling around I used a couple pieces of Velcro to hold them to the inner walls.

Here are a few pics during that phase of the project

The speaker would be installed in the middle section of the rifle. For there to be any sound at all, a hole would need to be drilled or exposed somewhere so the sound could come out and be heard, otherwise it would be muffled and impossible to hear.

I figured the best place to put it would be the vent slots where the barrel is. I only had to cut a hole large enough to match the diameter of the speaker. After I did that though I realized I wasn't satisfied with the way it sounded when it was in there. To make the most of it I fashioned a small cone around the speaker to focus and maximize the sound as much as possible. It just so happened that a paper towel roll was the perfect size for the speaker so I simply cut one down to fit and glued it in place. After that the quality was much, much better.

wub wub wub wub

inserted into place, starting to take shape

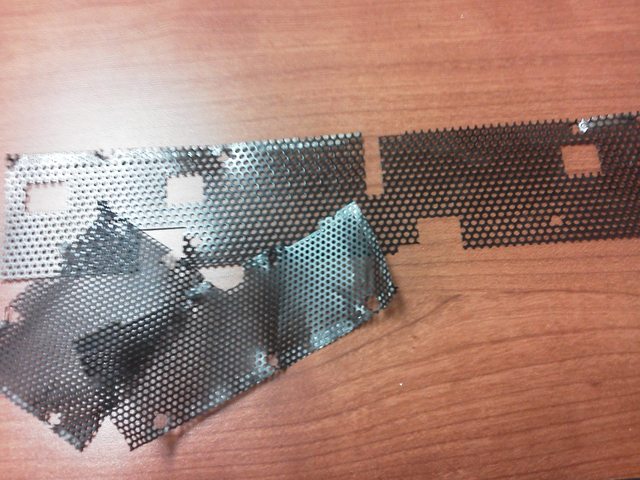

To conceal the hole I made in the middle section I took some speaker cover from an old netbook I had lying around. I cut it to size and then just super glued it over the vent slot. I think the result was pretty good!

The next section to install was the display counter itself. This was pretty challenging as there was a lot to fit into that small section. Initially I wanted to put the ammo counter right up and flush with the edge of the hole, but the casting here was pretty thin and I didn't want to risk removing too much material to make it fit, so I settled on pushing it back about ½ an inch or so. Not my first choice, but it works.

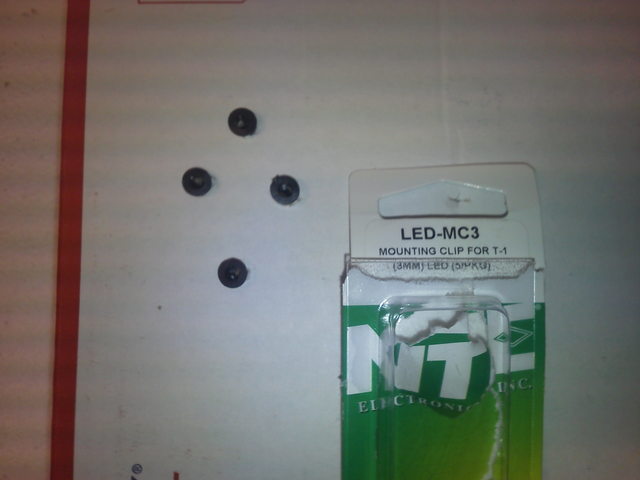

I also had to fit the 4 green LEDs into this section- these LEDs are on the side of the gun just below the counter. They were 3mm in size and to hold them into place I purchased some led holders from a local electronics store- it was $1 well spent haha.

I painted them and drilled holes just large enough to they’d insert into place easily. Once they were in and the LEDs clipped in I added a little hot glue to be safe.

Things were going really well at this point so it was only natural that I’d have a major setback :rolleyes

It took me long enough, but I've finally finished working on an Assault Rifle cast I got from Justinian almost a year ago.

The casting I received from him was near flawless- I had barley any filling and sanding that needed to be done which was great. I requested one of his hollow castings as I wanted to put electronics inside of it.

For electronics I wanted to include a display counter and if possible a sound system. Due to the size and profile of the AR I figured I wouldn't be able to put in a very large speaker, but still I really wanted to see if it was just possible to do, period.

Justin made his AR kit into modular parts, and they fit together like a glove after a little sanding. The only other work that needed done to the raw parts was drilling the hole for the barrel and the flashlight, and the holes for the wires so they’d have a conduit to run through.

Once I had the body work done (which hardly took any time, like I said, Justin really outdid himself with this) I began to play with how the pieces would fit together. I knew that once they were together I would have a hard time painting the seam and trying to get painters tape into some the finer areas would be a pain, so I went ahead and primed them and then gave them their main base coat for color.

The colors I used for this project were

-Krylon flat Black (lower receiver/grip)

-Krylon Satin Nickel (middle section)

-Rustoleum Dark Steel (upper receiver)

After they had a couple layers of their main colors painted, I started the assembly process. I decided to use JB Weld (a simple 2pt epoxy) to hold the pieces together. TO make this easier, I took my dremel and carved a channel in each piece on the joining surface and also scuffed up the surface to promote better adhesion. It also helped with keeping any spill over minimal when the pieces were pressed together.

After a day of waiting for the epoxy cure, I drilled the hole for the barrel and flashlight. Then it was time for the really fun part- the electronics.

My go-to for this part of the project is 405th regular thatdecade. First, I gotta tell you that he was a pleasure to work with through this whole project. Whenever I had a question (no matter how simple) he was able to answer it or help me work out a solution. There were also a couple of times I ran into somewhat large setbacks and he was able to help me out. He's probably as happy as I am this is done so he doesn't have to deal with me anymore

After I reached out to thatdecade and told him what I was planning to do, he was able to hook me up with a prototype for his new ammo counter display kits. The kit itself is pretty frickin cool- it has a trigger switch, a counter reset switch and an illuminated power switch. This is all ran off a standard 3 AAA battery pack.

When powered on, the counter starts at 32. When the trigger is pulled and held or pulsed the counter depletes to zero and can be reset by pushing the reset button. From there the cycle begins again.

If you've got an Assault Rifle, Battle Rifle or DMR prop I HIGHLY recommend one of his kits to take your prop to the next level. Speaking of the next level, the next thing I wanted to do with the kit was add sound.

Since this was more of an experiment for me I didn't want to spend too much money on a sound kit. It also would be required to run off the battery pack for the display counter so I didn't have a lot of options to work with. In the end, I decided to go with an inexpensive kit from http://www.electronics123.com/ for about $20. This kit has one small speaker that while not the loudest, would serve this purpose and also ran off a 3 AAA battery pack.

After getting the software for the board so I could program it I began feeding it sound files. I decided to use the Halo 4 assault rifle sounds because it sounds so meaty and since I had one small speaker I wanted to sound a ferocious as it could

Once I was satisfied with the sounds, I began to tackle how to integrate the sound board with the ammo counter board. I removed the battery pack from the sound board and then wired the board into the counters power source. Okay, so the boards both had power and could be turned on by the switch, so that was good. The next task was figuring out how to get the sound to play when the trigger was pulled. I figured out pretty early that I would just need to take the signal wire from the sound board and connect it to the trigger. When I did that, and pulled the trigger the sound loop would play but the counter would not do anything….hmmm. I knew I must be missing something simple but for the life of me I could NOT figure out what it was. I was starting to get frustrated so I consulted thatdecade to see what he thought and he informed me that I forgot the ground wire on the sound board (d’oh!).

So after a little rewiring, that ended up being exactly what the problem was. Now when the trigger was pulled the sound would play with it. Here is a sample of it during the testing phase (I apologize for the cell phone quality recording; it sounds much better in person).

Now that I had the wiring down it was time to start inserting the electronics into the AR cast. Fortunately, the holes I drilled earlier were large enough that they made feeding the wires pretty easy.

The sound board and battery pack would be installed into the AR’s fore grip section, and would be accessed by a removable section that stays held in place with magnets. To keep the battery pack and sound board from rattling around I used a couple pieces of Velcro to hold them to the inner walls.

Here are a few pics during that phase of the project

The speaker would be installed in the middle section of the rifle. For there to be any sound at all, a hole would need to be drilled or exposed somewhere so the sound could come out and be heard, otherwise it would be muffled and impossible to hear.

I figured the best place to put it would be the vent slots where the barrel is. I only had to cut a hole large enough to match the diameter of the speaker. After I did that though I realized I wasn't satisfied with the way it sounded when it was in there. To make the most of it I fashioned a small cone around the speaker to focus and maximize the sound as much as possible. It just so happened that a paper towel roll was the perfect size for the speaker so I simply cut one down to fit and glued it in place. After that the quality was much, much better.

wub wub wub wub

inserted into place, starting to take shape

To conceal the hole I made in the middle section I took some speaker cover from an old netbook I had lying around. I cut it to size and then just super glued it over the vent slot. I think the result was pretty good!

The next section to install was the display counter itself. This was pretty challenging as there was a lot to fit into that small section. Initially I wanted to put the ammo counter right up and flush with the edge of the hole, but the casting here was pretty thin and I didn't want to risk removing too much material to make it fit, so I settled on pushing it back about ½ an inch or so. Not my first choice, but it works.

I also had to fit the 4 green LEDs into this section- these LEDs are on the side of the gun just below the counter. They were 3mm in size and to hold them into place I purchased some led holders from a local electronics store- it was $1 well spent haha.

I painted them and drilled holes just large enough to they’d insert into place easily. Once they were in and the LEDs clipped in I added a little hot glue to be safe.

Things were going really well at this point so it was only natural that I’d have a major setback :rolleyes

Last edited by a moderator: