Hey peoples,

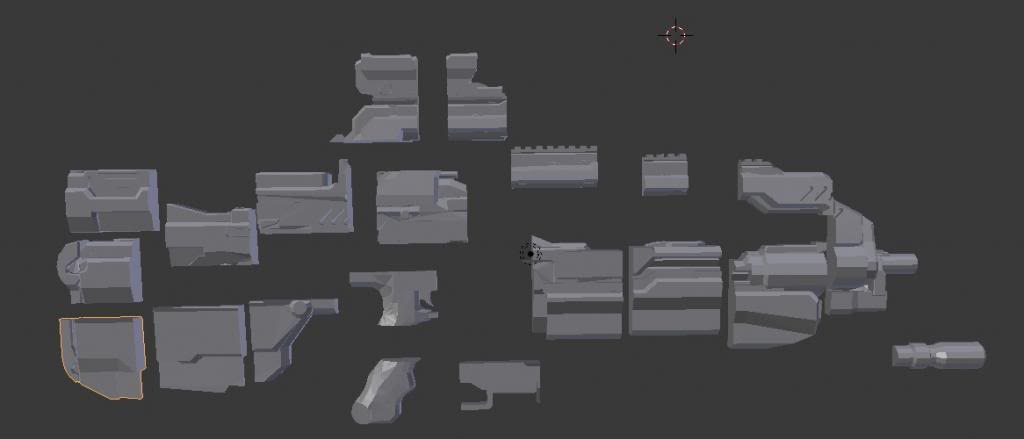

I've decided to really test this new printer I've acquired by printing out the entirety of the BR from Halo 4.

The original models come from a mix of WMHunterTLS's low res and high res models, and with the help of KingRahl I believe I've gotten them to a point where they may be printable.

In this instance I've cut in the whole model in half so it can be either glued up later or moulded in halves later... Still haven't decided.

Staring with the barrel, printing in ABS plastic.

The file I'm using can be found here:

http://www.thingiverse.com/thing:174602

I've decided to really test this new printer I've acquired by printing out the entirety of the BR from Halo 4.

The original models come from a mix of WMHunterTLS's low res and high res models, and with the help of KingRahl I believe I've gotten them to a point where they may be printable.

In this instance I've cut in the whole model in half so it can be either glued up later or moulded in halves later... Still haven't decided.

Staring with the barrel, printing in ABS plastic.

The file I'm using can be found here:

http://www.thingiverse.com/thing:174602