I'm anxious to see it, I vote Smoke Plastidip for color

LOL, and again... it seems that I get the post just after I went another route! Well, that and I already had three cans of black!

So, I wore the full Exo-suit for over an hour and a half, all the while doing normal things like climbing up and down stairs and making a cup of coffee and even using the restroom. All went fairly well, and let me know where I can improve just a few things to make this that much more comfortable. Heat was never an issue... in fact, I was cold for the most part. Granted, it is only 50F here today.

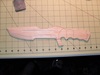

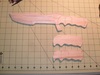

Parts I will be altering/adding to/repairing

Crotch area will finally get seamed up now that I know it will work properly

Codpiece to plate just above it will receive a snap buckle to keep it in place better

Repair on left arm by the wrist where a seam split just a bit (this should not happen anymore after I do the alteration listed next)

Add loops to the top portion of the arms where the strap from the shoulder will go through to keep the arm armor up my arm correctly.

I need to trim the lower portion of the outside of my leg armor just a bit to keep it from bunching on the boots... that or trim the outer side of the boot... either way I guess

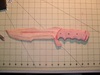

With that... here are some photos that were taken after the hour and a half.

I started off with trying the hex pattern, but my first pass failed, so I promptly went for full coverage. Unfortunately, the last can of Plasti-dip decided to spray like spackle or truck bed liner. Most of that self leveled, but I may revisit the arms for one more coat. I am not sure if it was because of temperature or what, but I was not pleased that it happened. Note: the can has no recommended temperature range for use... go figure!