Largo Usagi

Jr Member

First off this will be very picture heavy I have a DSLR I like to use so expect a large amount of pictures here.

Well I started my MK VI build today and this will be my first build ever. I thought starting with a small part would be easy to get familiar with peping but I found out that by choosing a small part that there is a **** load of little folds with even more little tabs and the whole thing ended up harder than what I was going for for a first pep piece. But hey all in all I got the experience and ended up with a some what terrible part. I don't know if resin and bondo can fix up the imperfections from this part so any input there would be great but I still have a Second of this part to make any ways.

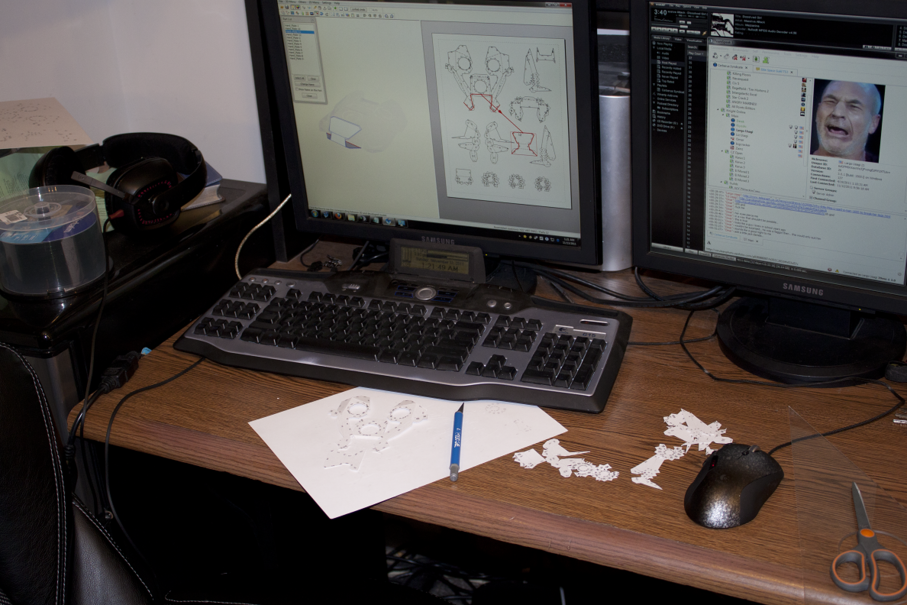

This is the workspace

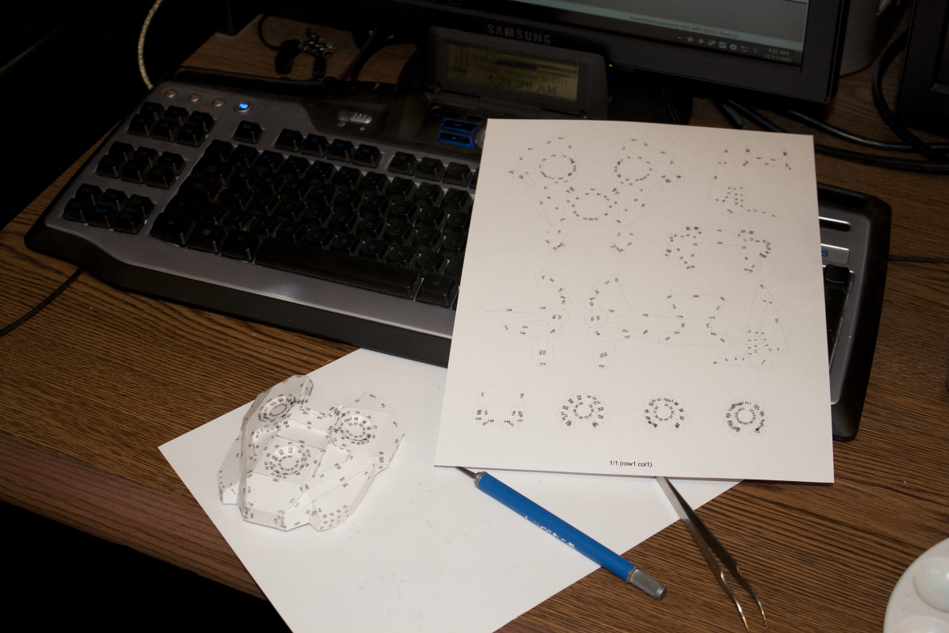

This is the first part I made finished from afar

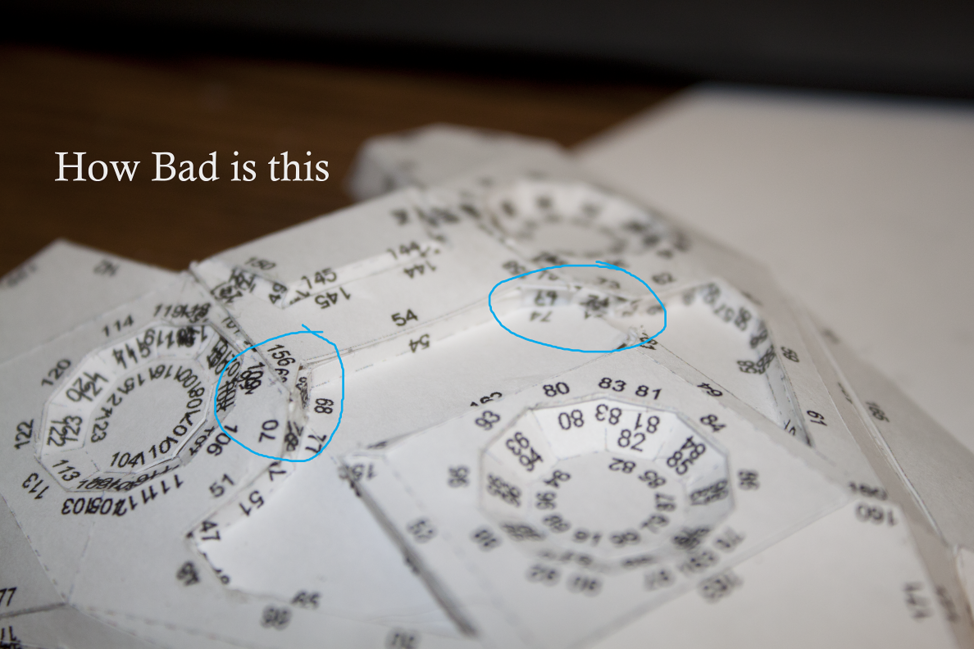

These are the imperfections that are worrying me

But hey at least i scaled it right on the first shot, I wasn't sure until about half way though I initially thought I made it to big

Well done with this for tonight and I will make another piece tomorrow.

Well I started my MK VI build today and this will be my first build ever. I thought starting with a small part would be easy to get familiar with peping but I found out that by choosing a small part that there is a **** load of little folds with even more little tabs and the whole thing ended up harder than what I was going for for a first pep piece. But hey all in all I got the experience and ended up with a some what terrible part. I don't know if resin and bondo can fix up the imperfections from this part so any input there would be great but I still have a Second of this part to make any ways.

This is the workspace

This is the first part I made finished from afar

These are the imperfections that are worrying me

But hey at least i scaled it right on the first shot, I wasn't sure until about half way though I initially thought I made it to big

Well done with this for tonight and I will make another piece tomorrow.