Quick update because I appear to have gotten a whole bunch of pics today. Magazine so far is 2 days' work.

This took the entire first day (after adding the remaining dimensions):

This is my Monday afternoon, basically:

The sticker from the matboard. I'll make sure this is smoothed down:

In place, more or less:

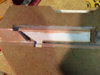

Here's some measurements for @Arcanine. This is how much space is available in back. Much more space available in front of the magazine than I thought there'd be. If you don't do a moving charging lever, that whole chamber section becomes available for use as well.

It may be that a pair of large diameter ultra-low profile speakers will fit in each side of the magazine, but I dunno. We'll see. It's a seriously hefty stock on the BR85, that's for sure. I may mould the magazine in two parts, so that people can access the bottom of the main compartment to cut it open and use it for something.

Tomorrow I do the "lid" and the exposed round. There was much discussion over in the ammunition thread about what exactly constitutes a HB BR round, but in the end I'm sticking with the asset dimensions of 13x80mm. That leaves room in the magazine not for 36 rounds, but 13. Nice one, Bungie.

All for now. Hopefully work begins on the stock itself by tomorrow afternoon. I'm starting to be thinking about ordering silicone! I'll do castings on demand, so purchasers, be aware: your order may take 3-4 weeks to arrive, since I have to order resin, wait on delivery, make the castings, then make up the shipping container and ship it out.

I just got an email from Digi-Key a few minutes ago, too. Switches have shipped, so hopefully they'll arrive by the end of the week, or maybe early next week.

This took the entire first day (after adding the remaining dimensions):

This is my Monday afternoon, basically:

The sticker from the matboard. I'll make sure this is smoothed down:

In place, more or less:

Here's some measurements for @Arcanine. This is how much space is available in back. Much more space available in front of the magazine than I thought there'd be. If you don't do a moving charging lever, that whole chamber section becomes available for use as well.

It may be that a pair of large diameter ultra-low profile speakers will fit in each side of the magazine, but I dunno. We'll see. It's a seriously hefty stock on the BR85, that's for sure. I may mould the magazine in two parts, so that people can access the bottom of the main compartment to cut it open and use it for something.

Tomorrow I do the "lid" and the exposed round. There was much discussion over in the ammunition thread about what exactly constitutes a HB BR round, but in the end I'm sticking with the asset dimensions of 13x80mm. That leaves room in the magazine not for 36 rounds, but 13. Nice one, Bungie.

All for now. Hopefully work begins on the stock itself by tomorrow afternoon. I'm starting to be thinking about ordering silicone! I'll do castings on demand, so purchasers, be aware: your order may take 3-4 weeks to arrive, since I have to order resin, wait on delivery, make the castings, then make up the shipping container and ship it out.

I just got an email from Digi-Key a few minutes ago, too. Switches have shipped, so hopefully they'll arrive by the end of the week, or maybe early next week.