beyonddead

New Member

Hi there,

I've been lurking here for a while and finally made the commitment to cosplay this year for NYCC. I got all the tools, a sharpener, a cutting mat, EVA Foam, Blades, X-Acto Knives, Etc Etc.

I started working on my ODST cosplay armor from DaFrontLineTrooper's tutorials. I've spent a few hours just sizing the shins until I got it all figured out.

I first printed it out on paper, then transferred it to cardboard for some measurements.

Finally, when I was happy, I started to cut the foam.

In my first cut, I thought it was kind of weird. I used a fresh, out of the box knife, and got a rough edge. However, most of my other cuts were fine.

I noticed that, long, straight or curved cuts can be flawless; but close and cornered cuts are jagged and rough.

Part of the tutorial requires bevels and 45 degree angles, which I just can't do. I tried everything, sharpnening, new blade, x-acto, and can't seem to cut the details in.

For example, If I'm trying to cut a bevel, I can cut the 90 degree half way fine, but when I cut into it with a 45 degree, it is almost spongelike and mush, won't cut.

As for 45 degree angles, if I'm doing it on a small piece, it'll keep mushing together too. As for corners. Below are some images of mine.

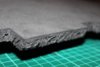

This is my attempt at a 45 degree angle.

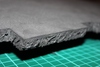

This is my attempt to bevel, the 90 degree is fine.

45 degree isn't...

Progress So far...

Thanks everyone, it looks like Andrew Cook in the videos can cut through these things like butter. I just can't seem to do it.

EVA Foam I'm using:

http://www.amazon.com/gp/product/B001E4XL3E?&redirect=true&ref_=oh_aui_detailpage_o03_s01

I've been lurking here for a while and finally made the commitment to cosplay this year for NYCC. I got all the tools, a sharpener, a cutting mat, EVA Foam, Blades, X-Acto Knives, Etc Etc.

I started working on my ODST cosplay armor from DaFrontLineTrooper's tutorials. I've spent a few hours just sizing the shins until I got it all figured out.

I first printed it out on paper, then transferred it to cardboard for some measurements.

Finally, when I was happy, I started to cut the foam.

In my first cut, I thought it was kind of weird. I used a fresh, out of the box knife, and got a rough edge. However, most of my other cuts were fine.

I noticed that, long, straight or curved cuts can be flawless; but close and cornered cuts are jagged and rough.

Part of the tutorial requires bevels and 45 degree angles, which I just can't do. I tried everything, sharpnening, new blade, x-acto, and can't seem to cut the details in.

For example, If I'm trying to cut a bevel, I can cut the 90 degree half way fine, but when I cut into it with a 45 degree, it is almost spongelike and mush, won't cut.

As for 45 degree angles, if I'm doing it on a small piece, it'll keep mushing together too. As for corners. Below are some images of mine.

This is my attempt at a 45 degree angle.

This is my attempt to bevel, the 90 degree is fine.

45 degree isn't...

Progress So far...

Thanks everyone, it looks like Andrew Cook in the videos can cut through these things like butter. I just can't seem to do it.

EVA Foam I'm using:

http://www.amazon.com/gp/product/B001E4XL3E?&redirect=true&ref_=oh_aui_detailpage_o03_s01