- Member DIN

- S386

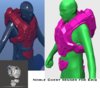

Re: Noble halo5 3D printing armor for a client

We figured out the mounting system for the legs.

so the black suit you see here has 2 holes on the outter leg to pass the snaps from the inner gurdle to the armor plates.

the Knees use a snap and some elastic .

Shins use his boots to origin them up to the right part and use foam under compression to center them.

Sholder is not mounted . but Same as the knees snap or 2 to origin them on the body suit and some elastic . they are hollow so theres not much mass to secure.

Peter..

We figured out the mounting system for the legs.

so the black suit you see here has 2 holes on the outter leg to pass the snaps from the inner gurdle to the armor plates.

the Knees use a snap and some elastic .

Shins use his boots to origin them up to the right part and use foam under compression to center them.

Sholder is not mounted . but Same as the knees snap or 2 to origin them on the body suit and some elastic . they are hollow so theres not much mass to secure.

Peter..