Hey All,

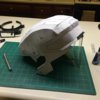

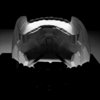

I got the itch to make one of these, so I dived into google and discovered both pepakura and 405th on the same day. You can see three weeks of progress in the photos attached.

I'm using 3mm EVA foam because I didn't realize cardstock was an option when I started, so this is purely a test helmet to get experience. Having said that, things are going pretty well considering I've never done this before. Advice welcome.

I got the itch to make one of these, so I dived into google and discovered both pepakura and 405th on the same day. You can see three weeks of progress in the photos attached.

I'm using 3mm EVA foam because I didn't realize cardstock was an option when I started, so this is purely a test helmet to get experience. Having said that, things are going pretty well considering I've never done this before. Advice welcome.