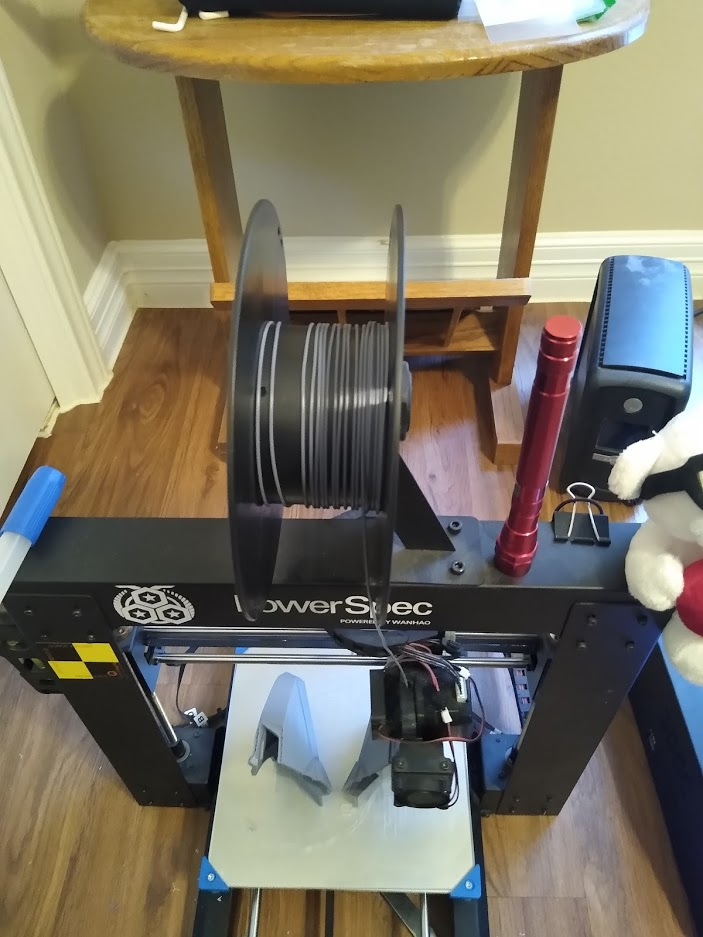

Since I have so much time on my hands lately I decided to finally get around to building my own armor. After a few agonizing weeks of me troubleshooting my 3D printer and tuning it, I am at the point where I can now print out quality pieces, and I can trust the thing to run overnight.

Thanks to Rainyfire for having the file sliced up properly and saving me a headache.

When printy boy prints you don't need to hover over it like you would while watching your child do her schoolwork at home.

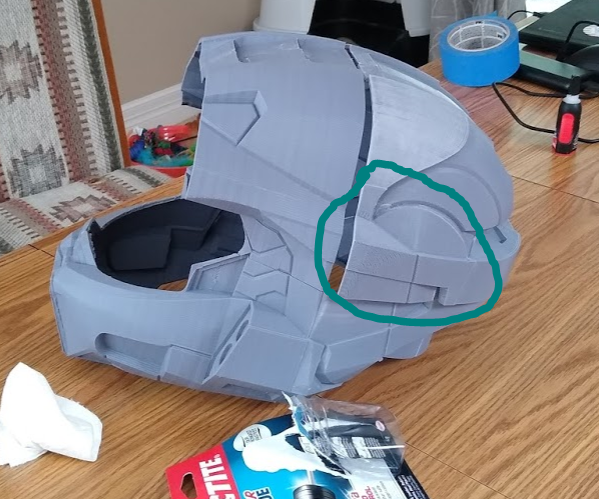

Once you have all the pieces printed out you can check fitment.

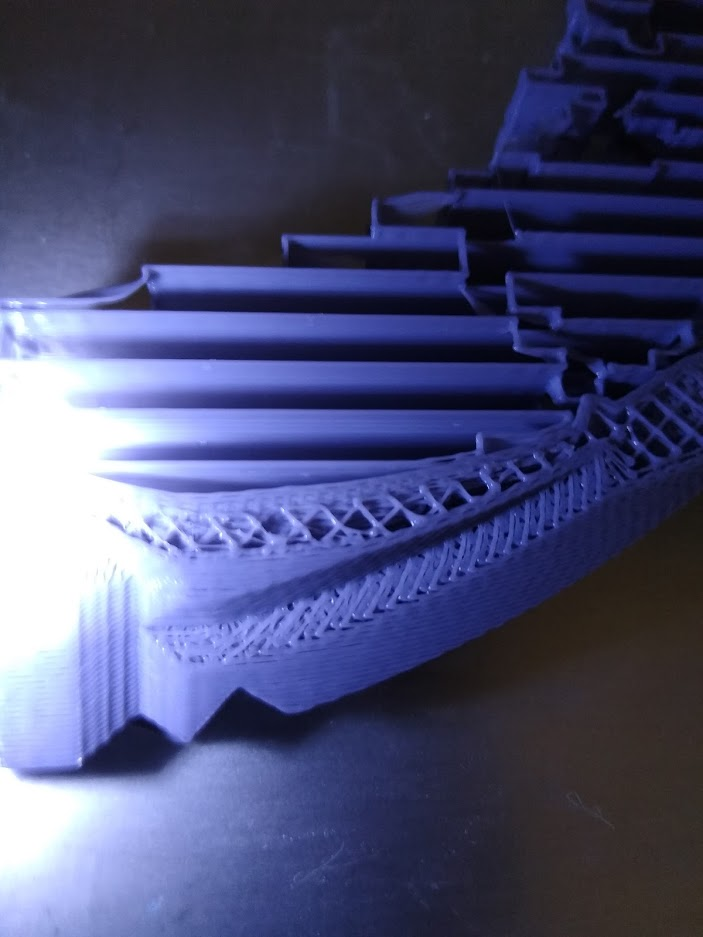

Sometimes things are going to line up perfectly and sometimes they aren't. As TurboCharizard helped me through this processhe made a very good point. If you want things to line up perfectly, the parts that will need to be glued should be on the bed of the printer.

I don't have that option due to the print bed size of my Wanhao. Some of the joints WILL end up being wonky, but we can fix these things in post production.

If you have armorsmith you should have scaled prior to printing. If not, be brave and print out the bottom half, or the neck seal area to check fitment. Mine did not fit, but I own a dremel. I can make it fit.

Using the painters tape we can get a rough idea of how are alignment is going.

Now that we got the bottom part lined up and glued, we can go check on our printer again. Always remind your buddies in discord to do a print check.

In this assembly I used Loctite liquid superglue. The gel stuff works but it doesn't bond as quickly.

You will glue yourself to yourself if you try to rush this part. Ask me how I know.

I know I have beautiful hands. I should have been a hand model, but we aren't here to discuss that. We are here to check more fitment as parts slowly come off of our printer.

If you look really close there is a small seam. This is what happens when you are 14 hours into a print and the power goes out. Slice the part off of the model you need to complete the print by moving it down the z axis in the slicer of your choice. Then you prepare that bad boy to print.

Then the power goes out again.

That wasn't a good day.

Another thing you need to do when printing is verify you have enough filament before you turn it on. I did not do that and came very close to messing this up.

Fitment. It may not work the way you want it to.

Now that we have a sortof glued together shell that will probably fall apart if we look at it wrong, we can reinforce it. I went with fiberglass because I like overkill. I'm 75% certain I could knock my kid out with this thing and it wouldn't break.

Thins aren't all going to be prefect, but we can fix this. It's bondo time.

Oh man, so much sanding. I started off with 60 grit because I am not a smart man. 100 would have worked fine.

I was going to avoid this picture because there is a lot to unpack here. I'm sanding something, why do i need an oven thermometer, a monkey wrnch, and a normal wrench? Because my buddy had resin I was going to use but it was old and I had a heck of a time getting it open. All of those tools were used, dont ask how or why, they just were.

Eventually you will get to the point where you've built up enough wood filler and bondo that it sortof resembles what you're going for.

Eventually you get to a point where seams are smooth enough that we can get around to paint.

BUT FIRST!!!!! We soak this puppy in epoxy to smooth out the print lines. I used some resin my buddy had leftover from a table build he did. It worked?

Filler primer. More magic forbidden dust. More sanding.

Decide you want to go green because people always fight over red and blue. Flat camouflage green.

Clearcoated with a can of satin clearcoat, then started weathering.

Then you need to look at reference photos and realize you forgot to paint black on it, so you have to go back and rework a bunch of stuff.

Next up, MoeSizzlac 's MK VI armor.

Thanks to Rainyfire for having the file sliced up properly and saving me a headache.

When printy boy prints you don't need to hover over it like you would while watching your child do her schoolwork at home.

Once you have all the pieces printed out you can check fitment.

Sometimes things are going to line up perfectly and sometimes they aren't. As TurboCharizard helped me through this processhe made a very good point. If you want things to line up perfectly, the parts that will need to be glued should be on the bed of the printer.

I don't have that option due to the print bed size of my Wanhao. Some of the joints WILL end up being wonky, but we can fix these things in post production.

If you have armorsmith you should have scaled prior to printing. If not, be brave and print out the bottom half, or the neck seal area to check fitment. Mine did not fit, but I own a dremel. I can make it fit.

Using the painters tape we can get a rough idea of how are alignment is going.

Now that we got the bottom part lined up and glued, we can go check on our printer again. Always remind your buddies in discord to do a print check.

In this assembly I used Loctite liquid superglue. The gel stuff works but it doesn't bond as quickly.

You will glue yourself to yourself if you try to rush this part. Ask me how I know.

I know I have beautiful hands. I should have been a hand model, but we aren't here to discuss that. We are here to check more fitment as parts slowly come off of our printer.

If you look really close there is a small seam. This is what happens when you are 14 hours into a print and the power goes out. Slice the part off of the model you need to complete the print by moving it down the z axis in the slicer of your choice. Then you prepare that bad boy to print.

Then the power goes out again.

That wasn't a good day.

Another thing you need to do when printing is verify you have enough filament before you turn it on. I did not do that and came very close to messing this up.

Fitment. It may not work the way you want it to.

Now that we have a sortof glued together shell that will probably fall apart if we look at it wrong, we can reinforce it. I went with fiberglass because I like overkill. I'm 75% certain I could knock my kid out with this thing and it wouldn't break.

Thins aren't all going to be prefect, but we can fix this. It's bondo time.

Oh man, so much sanding. I started off with 60 grit because I am not a smart man. 100 would have worked fine.

I was going to avoid this picture because there is a lot to unpack here. I'm sanding something, why do i need an oven thermometer, a monkey wrnch, and a normal wrench? Because my buddy had resin I was going to use but it was old and I had a heck of a time getting it open. All of those tools were used, dont ask how or why, they just were.

Eventually you will get to the point where you've built up enough wood filler and bondo that it sortof resembles what you're going for.

Eventually you get to a point where seams are smooth enough that we can get around to paint.

BUT FIRST!!!!! We soak this puppy in epoxy to smooth out the print lines. I used some resin my buddy had leftover from a table build he did. It worked?

Filler primer. More magic forbidden dust. More sanding.

Decide you want to go green because people always fight over red and blue. Flat camouflage green.

Clearcoated with a can of satin clearcoat, then started weathering.

Then you need to look at reference photos and realize you forgot to paint black on it, so you have to go back and rework a bunch of stuff.

Next up, MoeSizzlac 's MK VI armor.