marscreature

New Member

Doing my 1st weapon build and I chose the BR55 because I love Halo 2 and I already have the Boomco MA5.

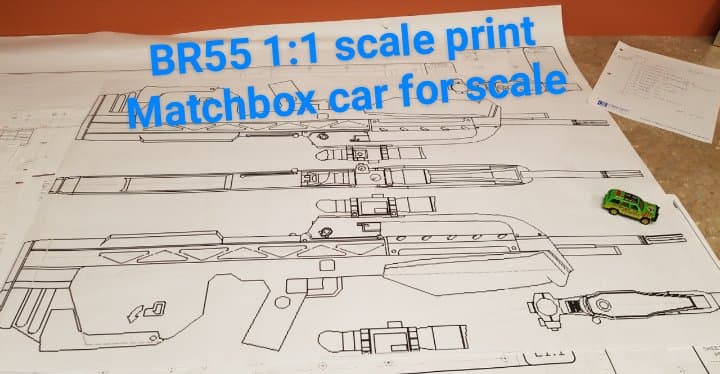

Started with Wizard of Flight's H3 Battle Rifle blueprint, then scaled it so I could print it full size.

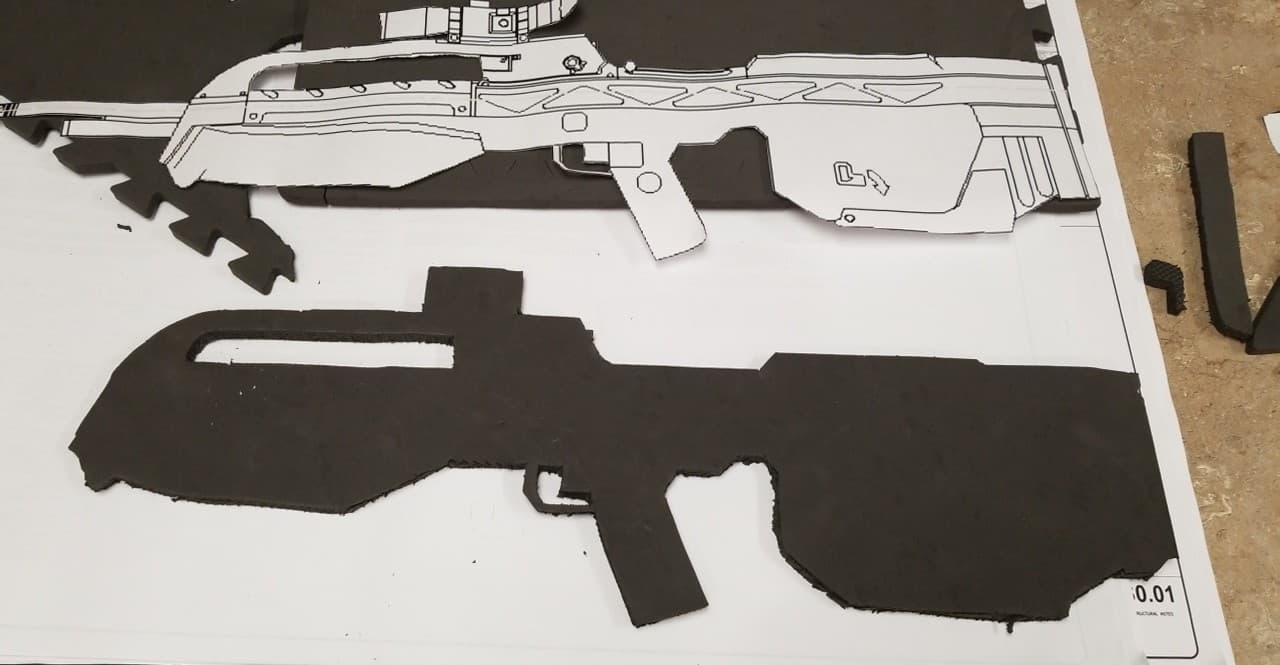

Cut it out then traced and cut it out of the foam.

Planning on using 1/2" PVC for the barrel and a nerf gun scope.

I will be putting a sheet of metal in between 2 foam layers to make it more rigid and hopefully magnetic enough to hold to the magnets I will be putting in my back armor.

Still debating on what to do for a coating before painting. Thoughts:

A. couple coats of elmers glue to keep it easy

B. 1 layer fiberglass mesh and resin on most and resin over all

C. thick layer of Duraglass fiberglass filler

Edit (9-11-18): probably going to just use plastidip

Started with Wizard of Flight's H3 Battle Rifle blueprint, then scaled it so I could print it full size.

Cut it out then traced and cut it out of the foam.

Planning on using 1/2" PVC for the barrel and a nerf gun scope.

I will be putting a sheet of metal in between 2 foam layers to make it more rigid and hopefully magnetic enough to hold to the magnets I will be putting in my back armor.

Still debating on what to do for a coating before painting. Thoughts:

A. couple coats of elmers glue to keep it easy

B. 1 layer fiberglass mesh and resin on most and resin over all

C. thick layer of Duraglass fiberglass filler

Edit (9-11-18): probably going to just use plastidip

Last edited: