Hello!

This will be the first of many posts on improving my Master Chief pepakura that I completed and worn for Comic Fiesta 2019 (Basically Malaysian comic con), after the event, I decided to repair and continuously improve based on the experiences before, during and after the con.

First all, the goals are:

As a preliminary stage, I already printed out armor pieces for chest, arm, legs and helmet for detailing purposes and pending the return of the box where I stored the pieces during the convention from a friend of mine. As it for now, I only have the helmet.

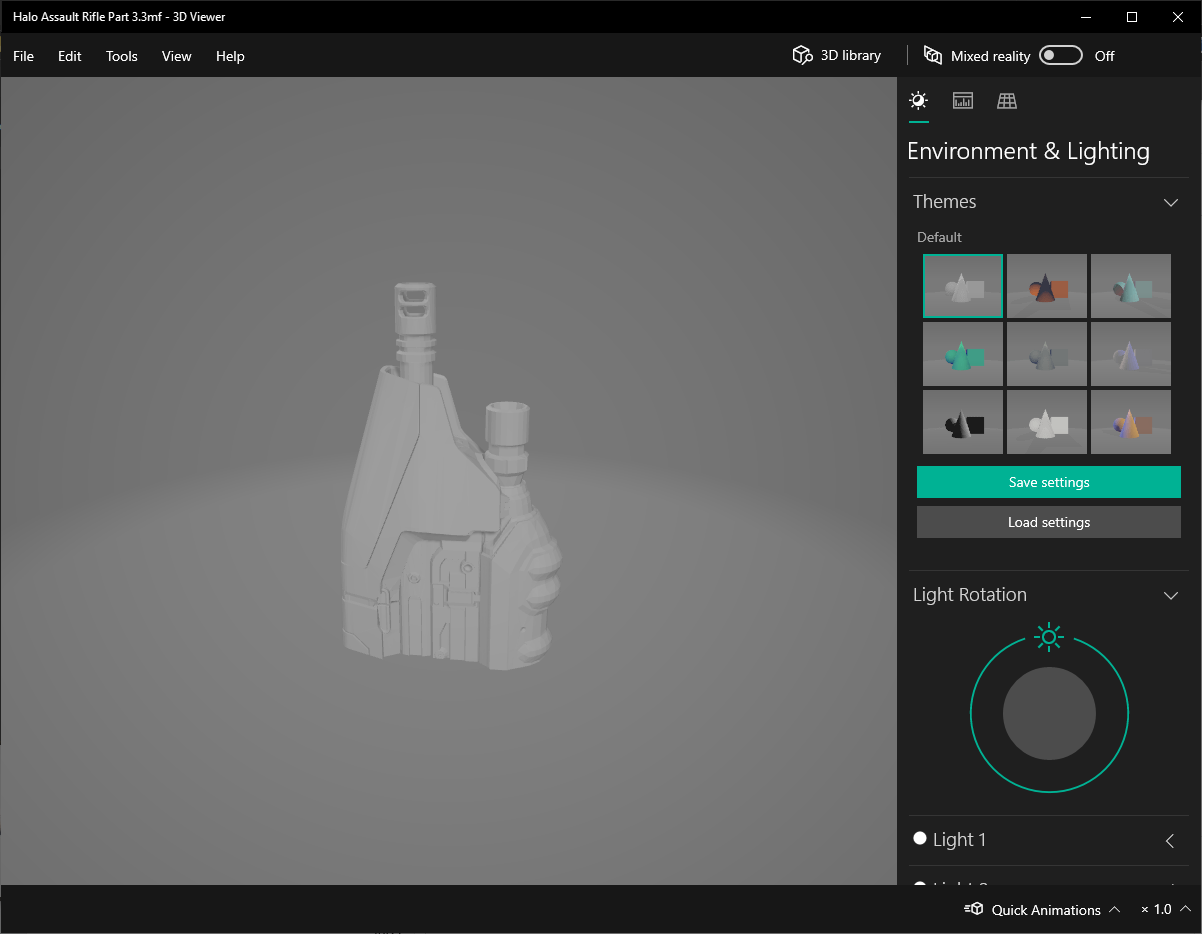

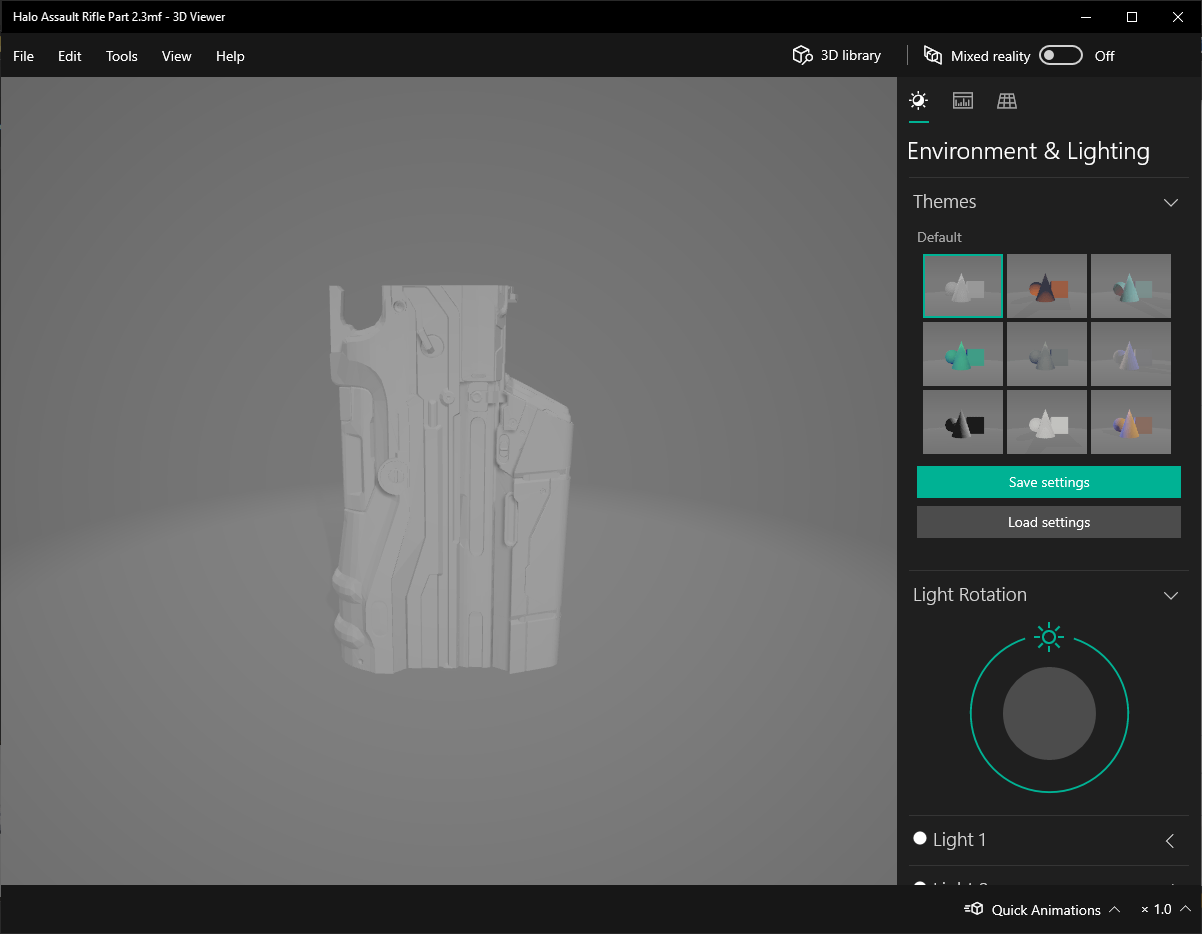

As for the weapon, I decided to head out and sourced a cheap but reliable 3D Printer from Creality and will due to arrive in a few weeks. The weapon I chosen is part of a set (halo-reach-unsc-ma37 icws-assault-rifle) and since the rifle would be too large, I decided to split it up into three parts and glue them together afterwards. Here are some screenshots of the pieces in the Microsoft 3D Viewer app.

That's it for today. I will update this thread once I got my 3D Printer.

This will be the first of many posts on improving my Master Chief pepakura that I completed and worn for Comic Fiesta 2019 (Basically Malaysian comic con), after the event, I decided to repair and continuously improve based on the experiences before, during and after the con.

First all, the goals are:

- Improve the strength of armor pieces so it won't get deformed during transit.

- A method to secure and fasten the armor pieces around my body so it won't move around

- Improve the mobility so I can make more action poses

- Produce a in-game-accurate weapon

- Increase the level of details and smooth out any hard edges from the pepakura construction.

As a preliminary stage, I already printed out armor pieces for chest, arm, legs and helmet for detailing purposes and pending the return of the box where I stored the pieces during the convention from a friend of mine. As it for now, I only have the helmet.

As for the weapon, I decided to head out and sourced a cheap but reliable 3D Printer from Creality and will due to arrive in a few weeks. The weapon I chosen is part of a set (halo-reach-unsc-ma37 icws-assault-rifle) and since the rifle would be too large, I decided to split it up into three parts and glue them together afterwards. Here are some screenshots of the pieces in the Microsoft 3D Viewer app.

That's it for today. I will update this thread once I got my 3D Printer.