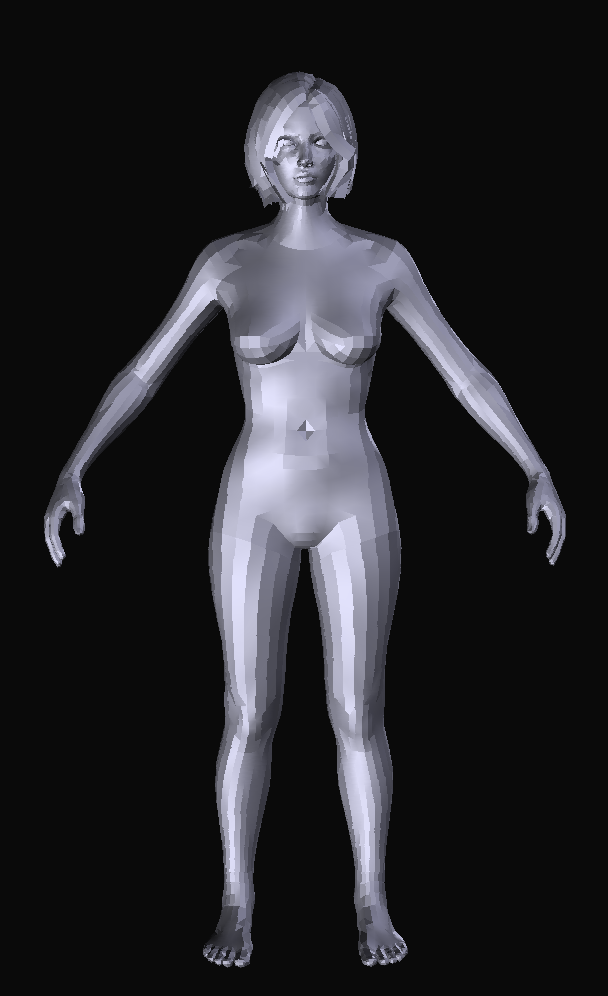

I'm planning a 3D printing project using Cortana as a gift for someone, and I've managed to get an export of the game model to use for reference. The problem is, the game model is fairly low-poly, and will not print well. Does anyone have a higher poly version of the model, preferably with bones so it can be posed before exporting to .stl?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Halo 4 Cortana model for 3D Printing

- Thread starter GeneralMayhem

- Start date

-

- Tags

- 3d printing cortana halo 4 modeling

- Status

- Not open for further replies.

Nuts4Accuracy

Active Member

Cant you smooth it?

you could try the "Subdivision Surface" tool in blender. First, you'll have to select the edges you want to sharpen by entering the edit interface (press TAB) then paint the edges you want using Shift+Left Click. Add all the edges you want to the selection, and use Shift+E and type 1.0 to sharpen the edges. press Tab again to exit the edit interface, and click the wrench on the right tab to open the modifiers drop down. After that, there should be another drop-down that says "add modifier", which houses all the differing modifiers. You'll want to click "Subdivision Surface" tool, and modifying the settings until you get the desired result.

The textures should carry over into the final model, but i'm not 100% sure. If you're unfamiliar with Blender, I can probably help you with the model.

So, I should also mention that it will be easier to pose the model while it is in low-poly form as high-poly models can stress out a program. You'll need to rig the model as well in a program such as Autodesk Maya.

The textures should carry over into the final model, but i'm not 100% sure. If you're unfamiliar with Blender, I can probably help you with the model.

So, I should also mention that it will be easier to pose the model while it is in low-poly form as high-poly models can stress out a program. You'll need to rig the model as well in a program such as Autodesk Maya.

I'm not familiar with blender at all, and simply subdividing what's there isn't the issue, as it's not a matter of what it looks like in a render, so much as the fact that printing depends entirely on the actual geometry. Essentially every polygon is going to be reproduced "as is" when it is sliced for printing. I'm considering using the preview render as a guide, and tweaking a figure in Poser to match Cortana's proportions, then posing and exporting a model from there.

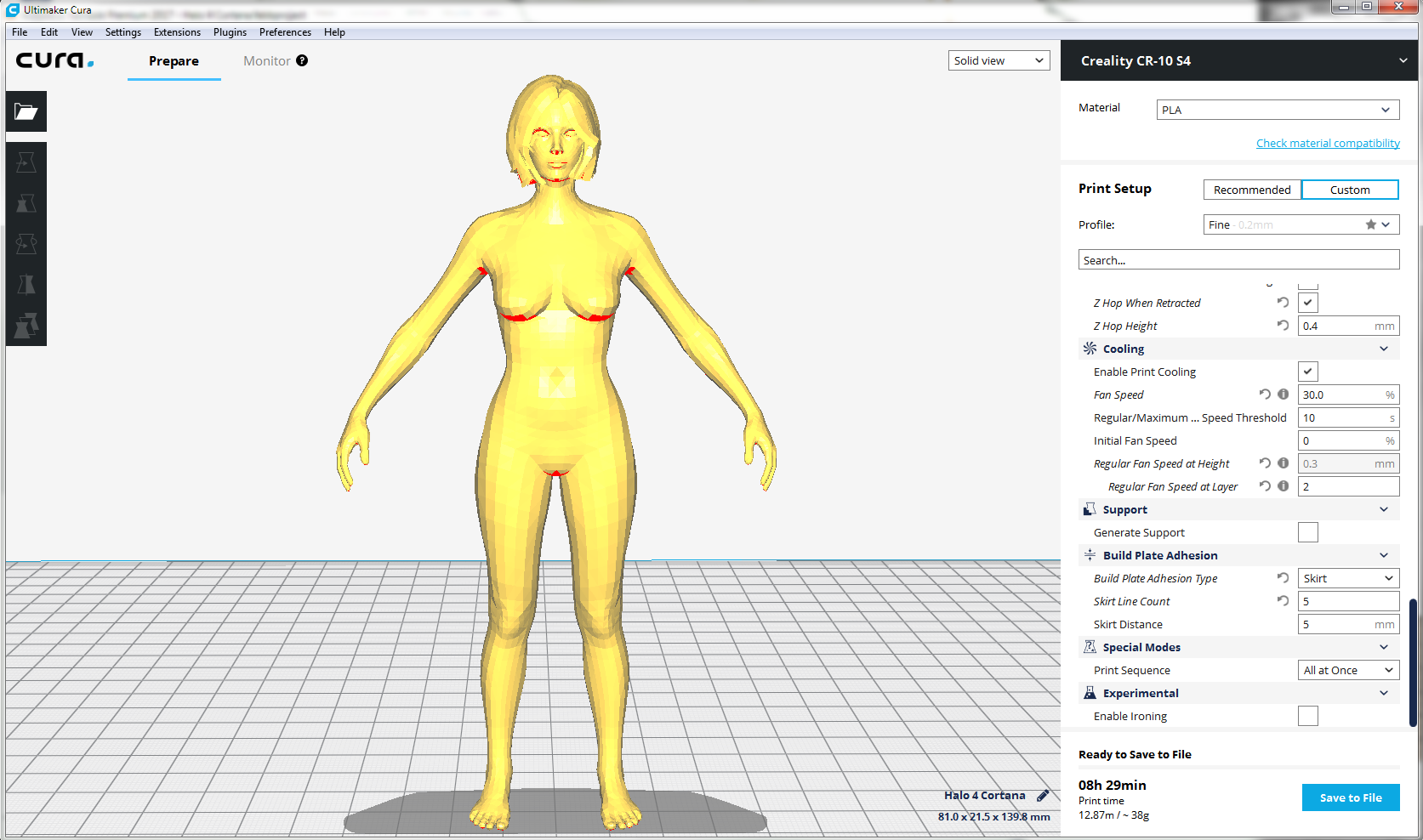

This is what the base model looks like in a slicing program. As you can see, the smoother the mesh, the smoother the final print will be. This resolution might be ok if I wanted a very small print, but what I'm thinking of calls for a figure that might be 8-10 inches tall.

Subdividing the surface (in the manner I am speaking of, Catmull-Clark) can actually increase the resolution and smoothness of a model. I'm not referring to simply increasing the face count, let me get you a pic.I'm not familiar with blender at all, and simply subdividing what's there isn't the issue, as it's not a matter of what it looks like in a render, so much as the fact that printing depends entirely on the actual geometry. Essentially every polygon is going to be reproduced "as is" when it is sliced for printing. I'm considering using the preview render as a guide, and tweaking a figure in Poser to match Cortana's proportions, then posing and exporting a model from there.

Before:

After:

up-close:

much higher poly model, much smoother as well. The trick is to crease certain edges so that it retains the proper shape.

Do you understand what i'm getting at?

I see. Unfortunately, I'm a total newbie when it comes to blender.

If you're printing Cortana upright, you'll end up having a lot of filament wasted on support struts. Even if you lay her on her back, the back probably won't be as smooth due to the attachment points of the support geometry (not sure how other 3d printers go, I only have a derpy little "DaVinci jr"). Personally I'd slice her down the middle so her front and back are separate halves, then glue them together afterwards.

The pose you're seeing her in is just the model's default pose, not the pose I'm planning on printing her in. Also, I'll be printing her in translucent PLA, so I will print her all in one piece. I have a Creality CR-10, with a build volume of 400mm x 400mm x 400mm, so the size of the final model is not going to require any assembly other than the separate pieces that will go together, such as the base, which I'm planning to make from a model of Cortana's chip. The completed piece will be lit from beneath by an LED circuit and a battery pack hidden in the base.

As you can see from this 3D printed full sized Battle Rifle, My printer is capable of larger prints with no worries.

As you can see from this 3D printed full sized Battle Rifle, My printer is capable of larger prints with no worries.

View attachment 251428

Yeah I have a little babby printer so I'm constantly thinking about economic printing. If I had known about the Crealty's I would've bought one of those instead.

What's the layer height on the battlerifle? Pretty cool. Seeing all these armors and stuff with different panels/detail lines I've been tempted to re-create a set so the different parts align accurately. Not sure if it would work or not... would be fun to assemble a set of MJOLNIR Mark VI game-accurate XD.

I used a layer height of .1mm for all the battle rifle parts, with 15% infill, because I wasn't in a rush, and I wanted to save myself some time sanding. Everything was printed in smaller sections, with some parts combined to save on assembly. I printed it over the course of about two weeks or so. Printing cost isn't much of a concern, since I'm only paying between $10-15 a KG for filament since I found a couple of very reasonable brands/vendors to buy from. The BR used about $25 worth of filament, so I have no complaints if a print fails and I have to reprint a part or two.

Well, if you want to pose her, I can smooth the model for ya afterwards.I see. Unfortunately, I'm a total newbie when it comes to blender.

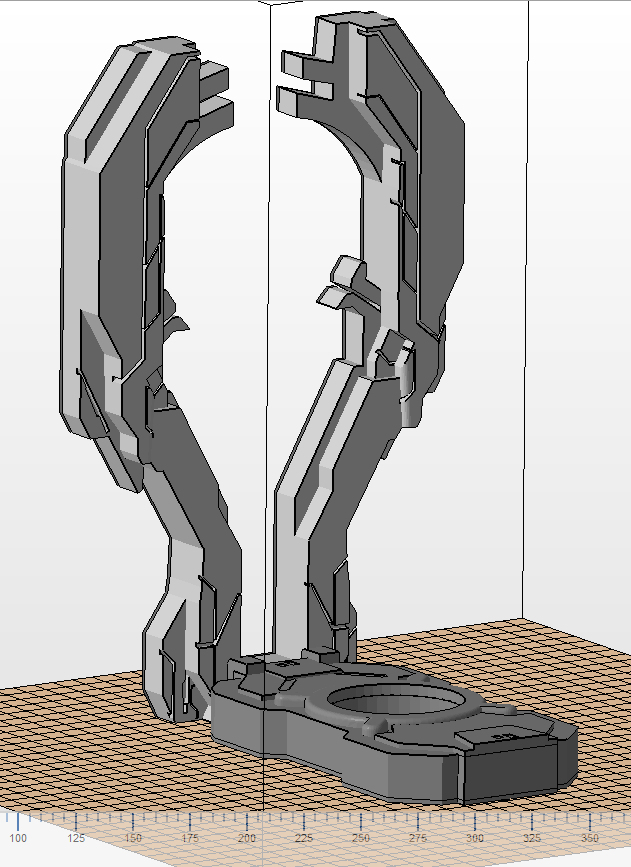

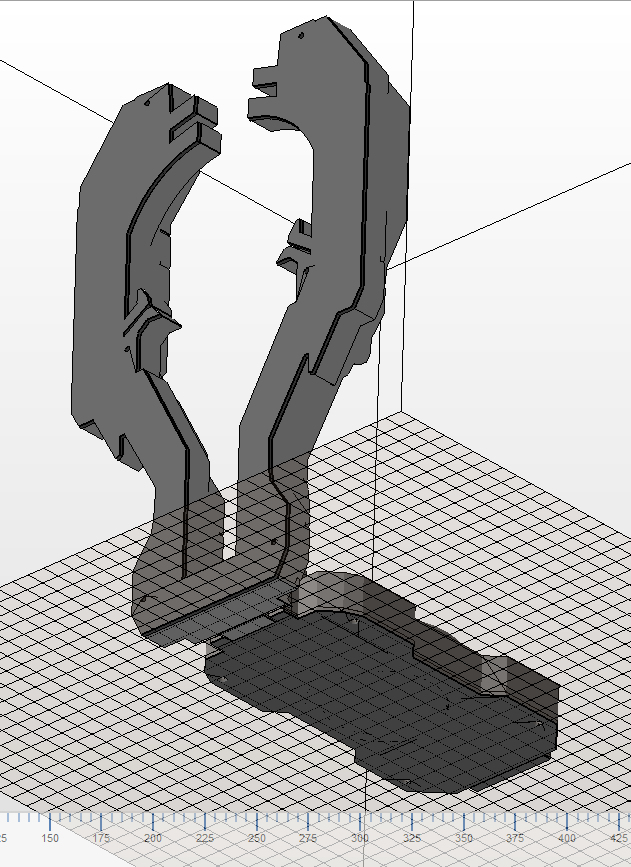

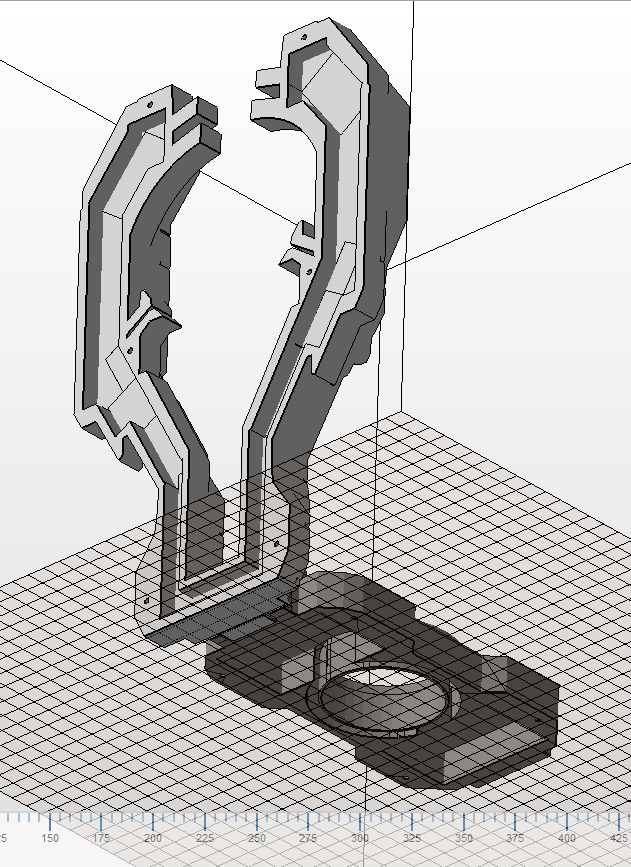

Here's an update. I've got the stand itself worked out, and I'm currently printing my second iteration of the parts for it. My first run didn't have enough space for lighting the back piece, and my first chip was split across the middle instead of featuring a bottom plate. I found an inexpensive string of color changing "fairy lights" to light the stand with, and the main parts are being printed in translucent PLA.

The back and internals...

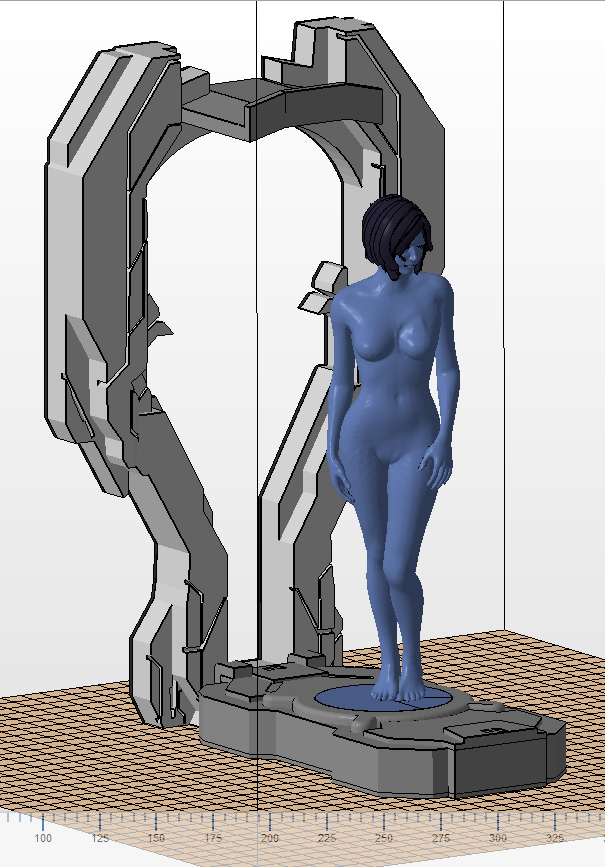

Headphone clip added, Cortana is now posed, with a surface subdivision smooth in Blender (I took your advice, mblackwell1002), and her hair split off to be printed separately.

Headphone clip added, Cortana is now posed, with a surface subdivision smooth in Blender (I took your advice, mblackwell1002), and her hair split off to be printed separately.

Lookin' nifty! You might want to smooth out the weights (weight paint mode) where the left breast meets the sternum.

Did you make your own rig or use something like "Rigify"?

I used the original rig from the game model. I'm not too worried about the model being flawless, as the whole thing will be sanded post printing, and then painted.

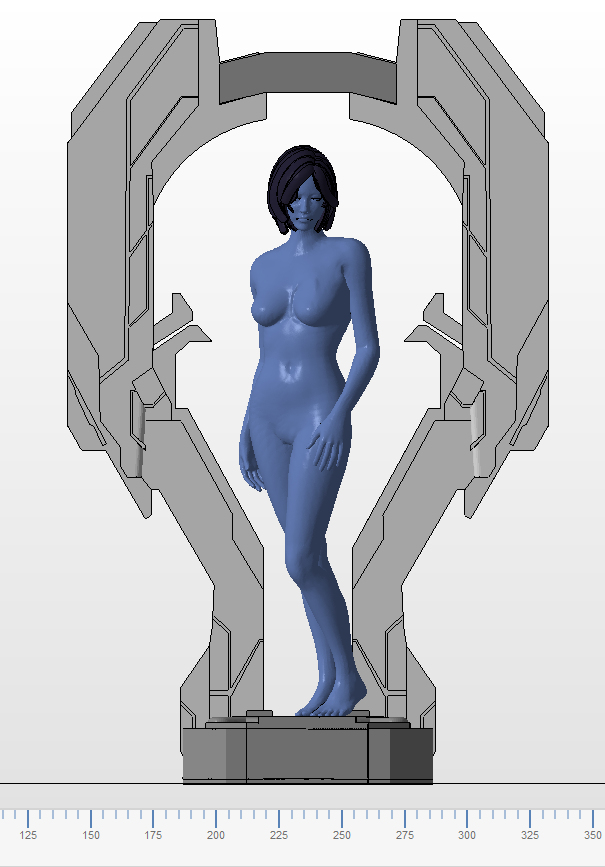

Stand parts are printed, but still need sanding and painting. Cortana is printing now.

Here's Cortana. Final pose, and second print, after I decided that her feet needed a little support due to only her toes making contact with the base.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 406

- Replies

- 2

- Views

- 334