nekothecat

New Member

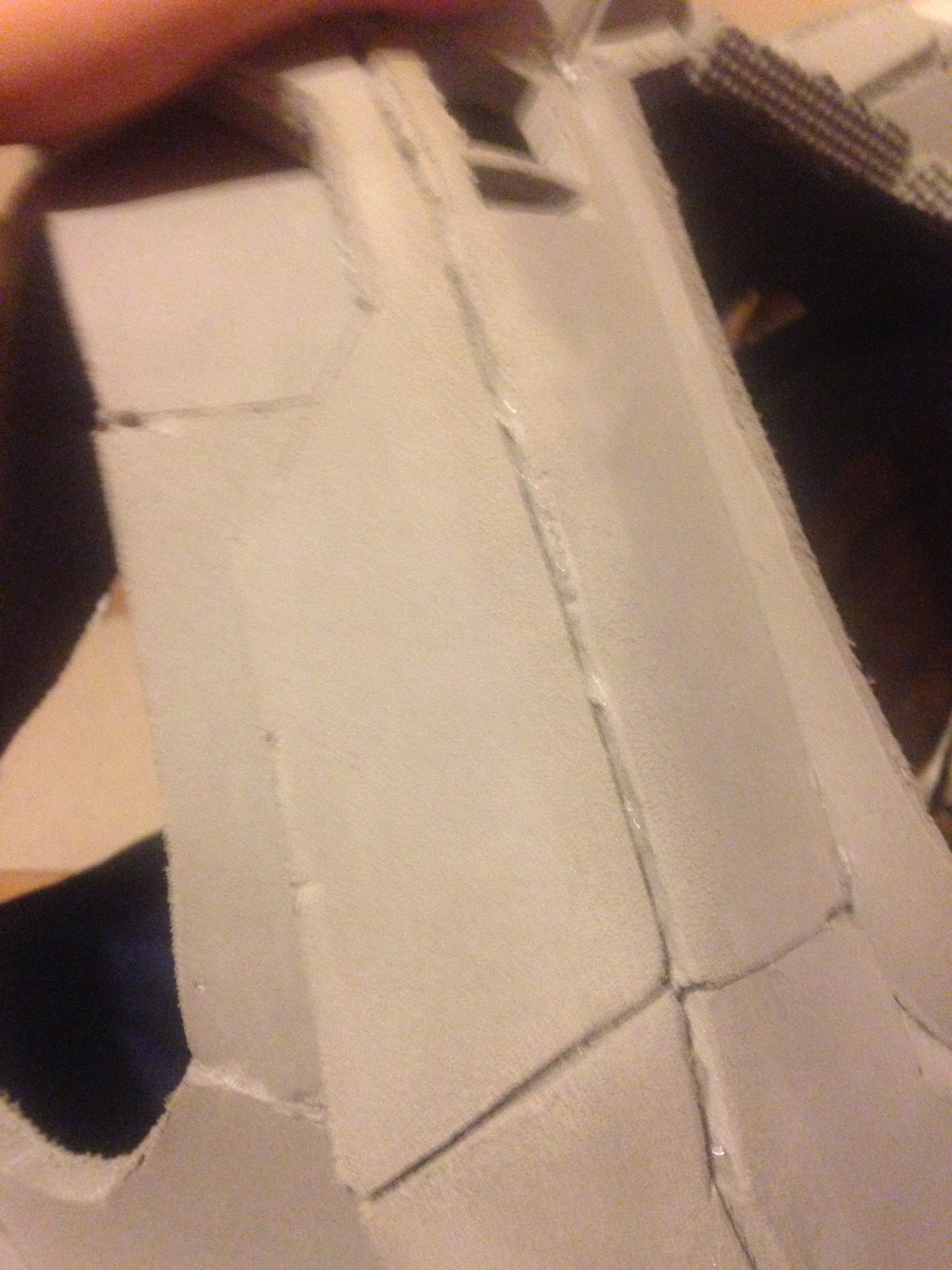

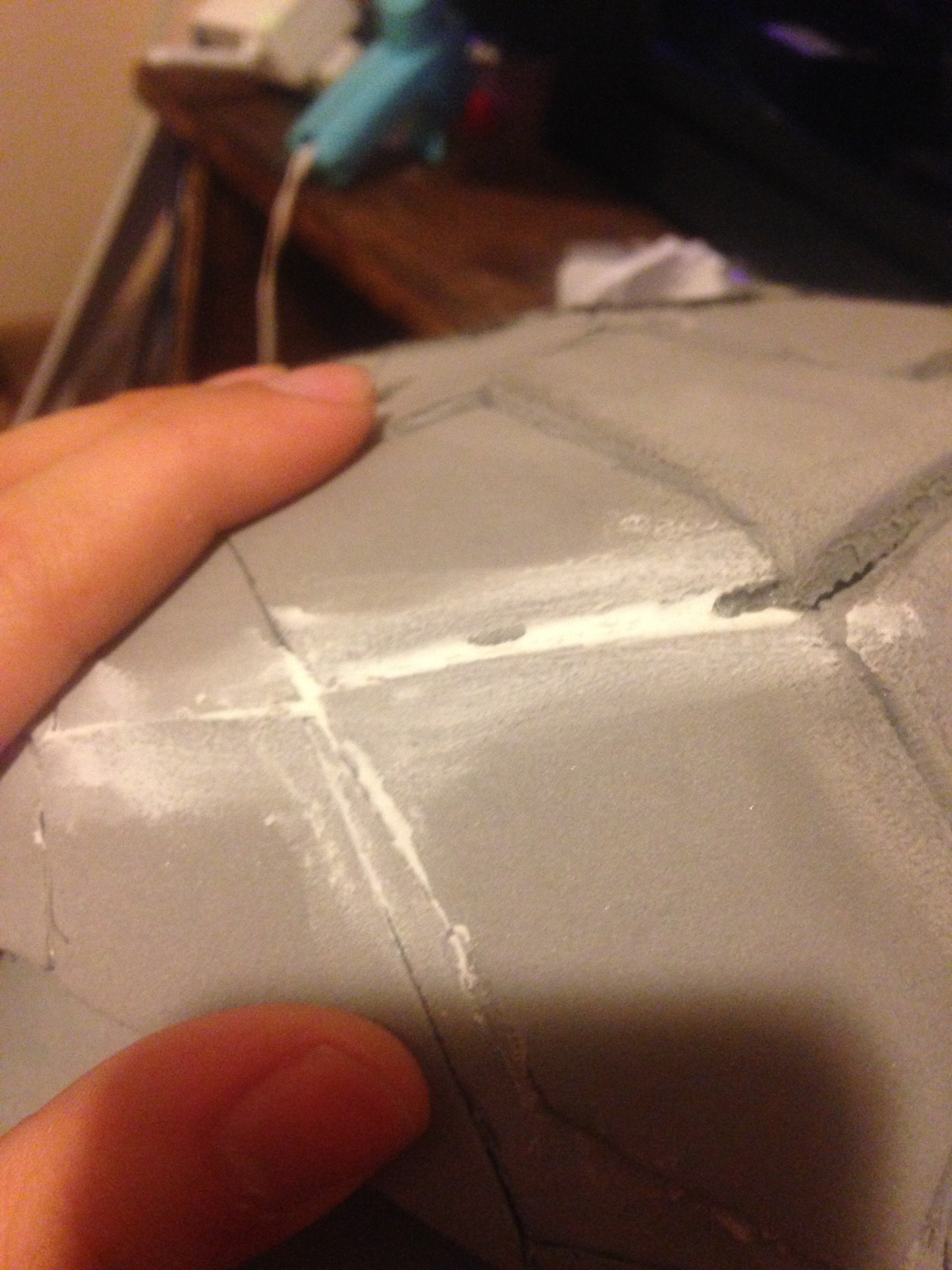

so I have a little problem. I finished my foam armor set but now I have to worry about glue seams and large gaps. I used all purpose silicone sealant and I don't know if it'll stick I feel like it would just peel off.

can anyone recommend any product that is within budget range.

I will soon fix the rough edges and deep gaps with sand paper to lower them so not much material will be used to fill gaps!

can anyone recommend any product that is within budget range.

I will soon fix the rough edges and deep gaps with sand paper to lower them so not much material will be used to fill gaps!

Last edited by a moderator: