rah66

New Member

First: Hi.

My name is Jakob, I'm a 26year old engineering student from Germany, currently living and studying in Sweden.

I enjoy playing Halo (well, that's why we're here, isn't it?) and tinkering around, so I thought of building some nice Halo guns.

Well, there's not much to tell about me - but I want to show you my first project so far and maybe get some valuable feedback from you.

I'm am not much of a forum user, and as well I'm not native to the english language, so please apologize any mistakes in language or etiquette...

But here's my first baby:

It's a Nerf Stryfe Elite with a custom made barrel and shoulder stock.

All additional parts are created in CREO2 (CAD-software) and then printed on a 3D printer. Because I had only one shot at the printer (sadly not my own), I had to work with prototype parts including all the flaws (see list at the end of the post).

But with a little fiddling and filing here and there, and some cardboard patches, it all fit together snugly. The whole gun can be disassembled with 7 screws (plus those of the Nerf gun). It is still shooting well and fully automatic. Only minor mods to the interior of the Nerf gun, like removing some restrictions. The light underneath the barrel can be substituted with a mini-Maglite. In the shoulder stock is space for a spare magazine.

Here are some more pictures and a drawing of the CAD parts.

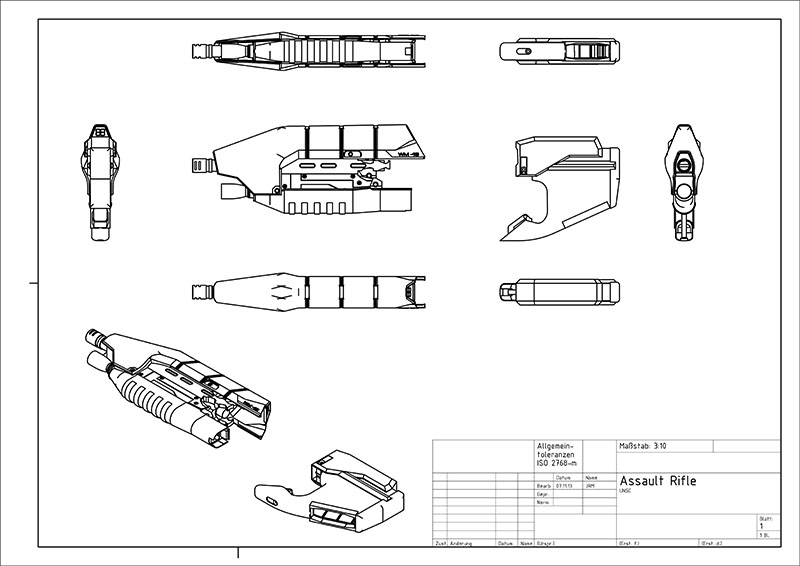

CAD drawing

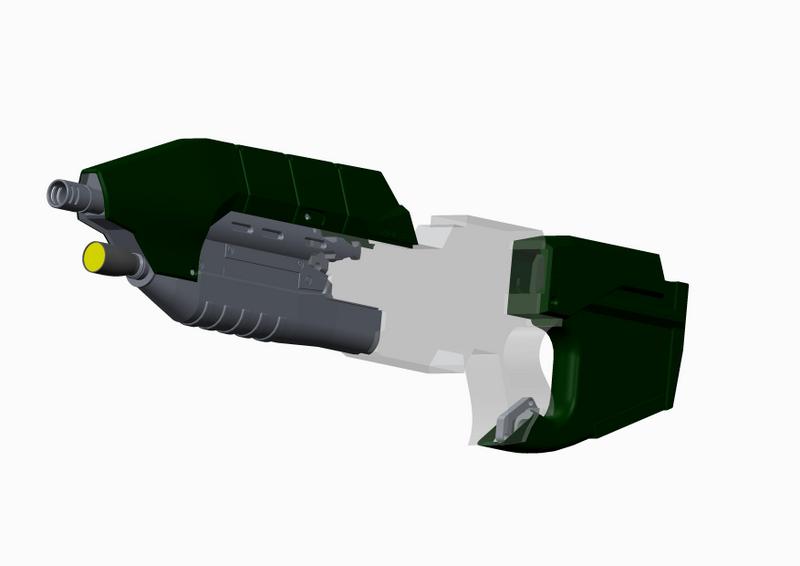

CAD 3D data, with Nerf gun in "glass"

assembly, Nerf gun grey, magazines orange, rp-parts white

not me...

oh, and i know, the paint job is horrible... i have to learn a lot there for my next project, which will be a Nerf Longshot sniper (like from Reach) mod in foam, and if foam and i get along well, a Jun266 armor suit... in the future, sometime...

maybe around christmas i'll see the gun again, and get some better pictures... above are only phone-shots.

If anyone is interested in the CAD-files, PM me. But they need some more work done, which i haven't had the time for so far (i'll do it if I have again the chances to use a 3D printer):

- increase wall thickness to min 2mm

- more accuracy around the connection of Nerf-front and barrel (I did a very bad job measuring the shape of the original gun)

- increased gaps at the connection of shoulder stock

- little bit more detail on the stock

and it would of course be possible to add some electronics for a illuminated ammo-count... but it was a birthday present (yes, i gave it away ) and i was running out of time.

) and i was running out of time.

My name is Jakob, I'm a 26year old engineering student from Germany, currently living and studying in Sweden.

I enjoy playing Halo (well, that's why we're here, isn't it?) and tinkering around, so I thought of building some nice Halo guns.

Well, there's not much to tell about me - but I want to show you my first project so far and maybe get some valuable feedback from you.

I'm am not much of a forum user, and as well I'm not native to the english language, so please apologize any mistakes in language or etiquette...

But here's my first baby:

It's a Nerf Stryfe Elite with a custom made barrel and shoulder stock.

All additional parts are created in CREO2 (CAD-software) and then printed on a 3D printer. Because I had only one shot at the printer (sadly not my own), I had to work with prototype parts including all the flaws (see list at the end of the post).

But with a little fiddling and filing here and there, and some cardboard patches, it all fit together snugly. The whole gun can be disassembled with 7 screws (plus those of the Nerf gun). It is still shooting well and fully automatic. Only minor mods to the interior of the Nerf gun, like removing some restrictions. The light underneath the barrel can be substituted with a mini-Maglite. In the shoulder stock is space for a spare magazine.

Here are some more pictures and a drawing of the CAD parts.

CAD drawing

CAD 3D data, with Nerf gun in "glass"

assembly, Nerf gun grey, magazines orange, rp-parts white

not me...

oh, and i know, the paint job is horrible... i have to learn a lot there for my next project, which will be a Nerf Longshot sniper (like from Reach) mod in foam, and if foam and i get along well, a Jun266 armor suit... in the future, sometime...

maybe around christmas i'll see the gun again, and get some better pictures... above are only phone-shots.

If anyone is interested in the CAD-files, PM me. But they need some more work done, which i haven't had the time for so far (i'll do it if I have again the chances to use a 3D printer):

- increase wall thickness to min 2mm

- more accuracy around the connection of Nerf-front and barrel (I did a very bad job measuring the shape of the original gun)

- increased gaps at the connection of shoulder stock

- little bit more detail on the stock

and it would of course be possible to add some electronics for a illuminated ammo-count... but it was a birthday present (yes, i gave it away