Hello Spartans,

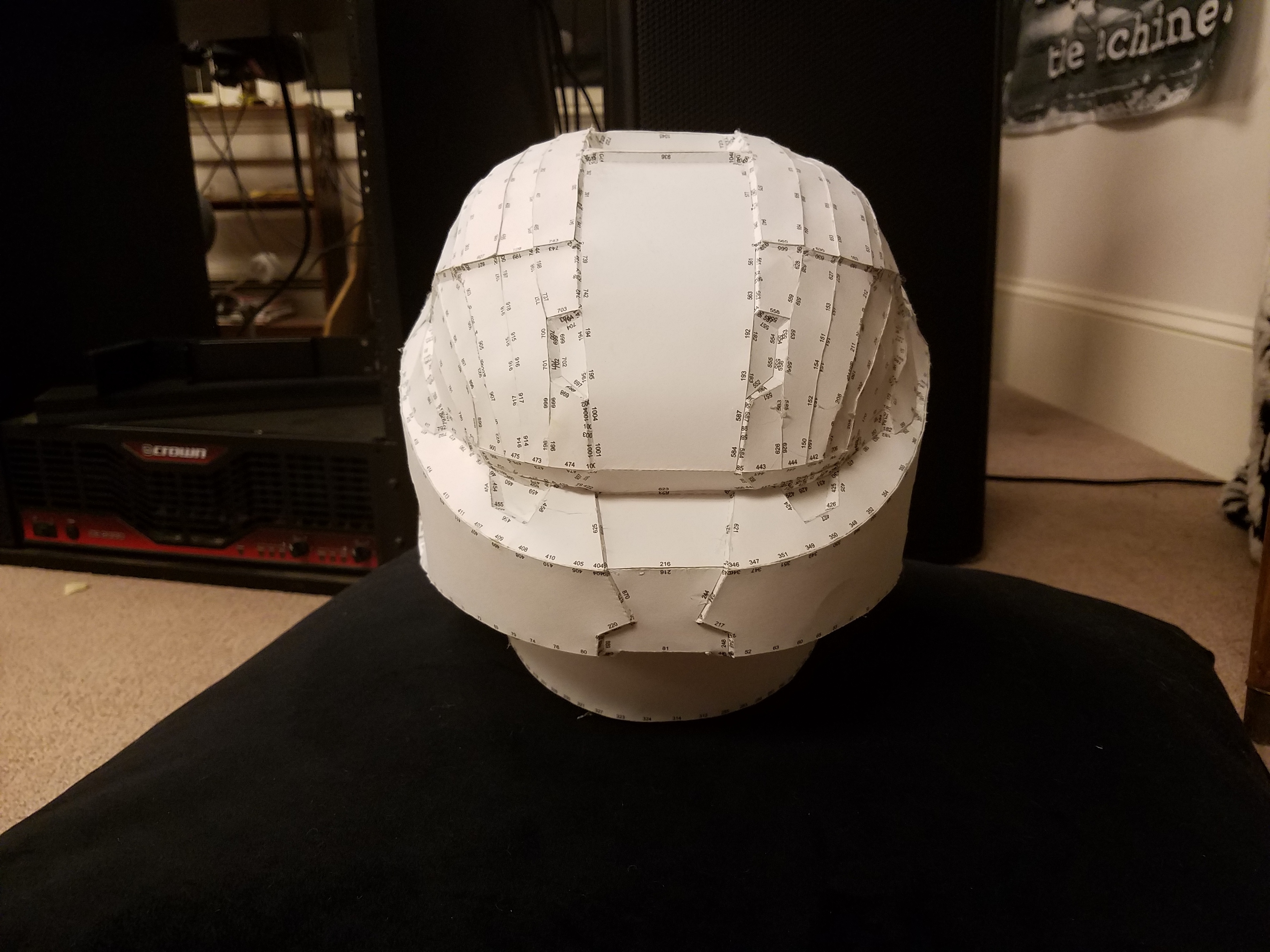

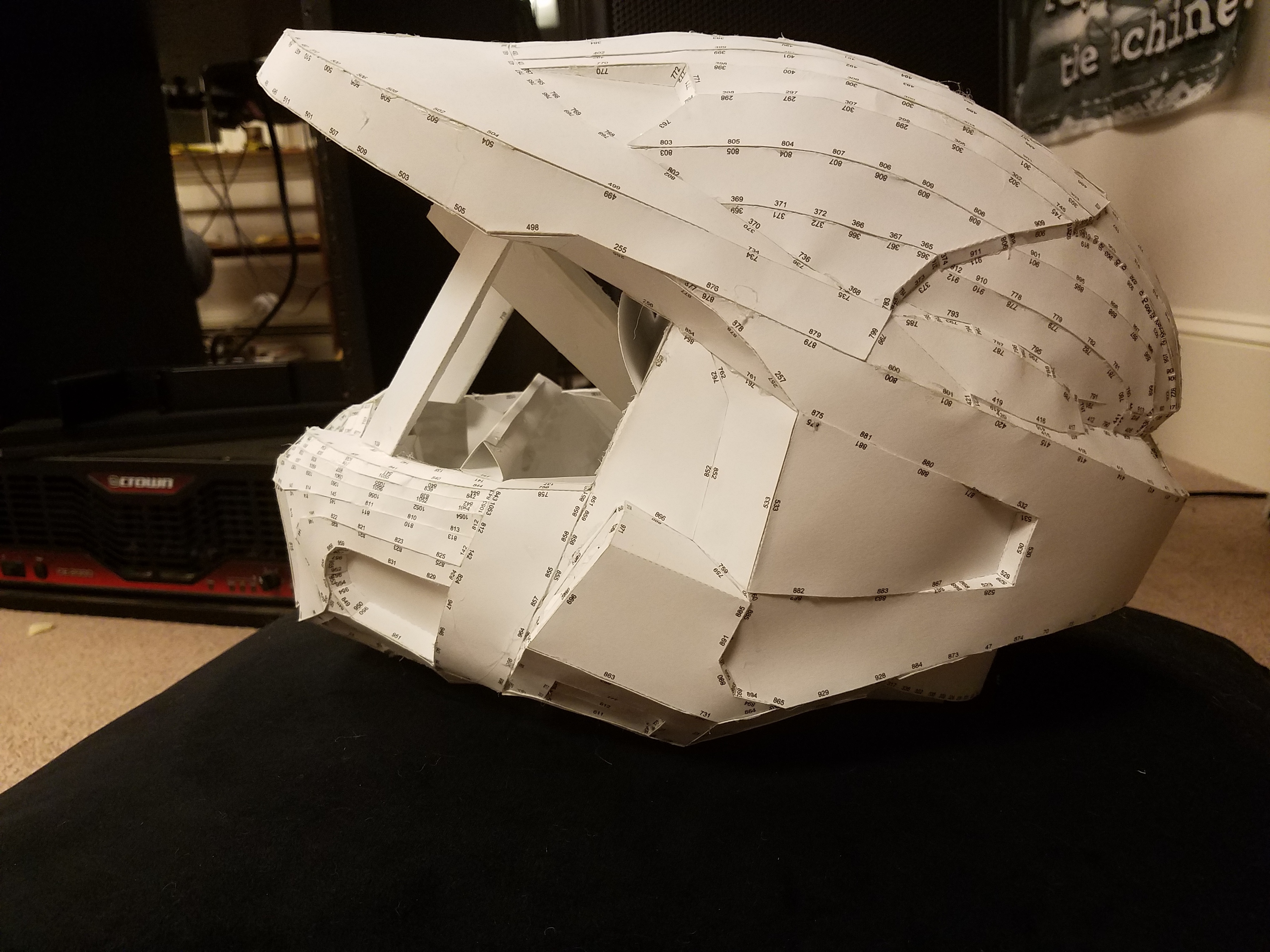

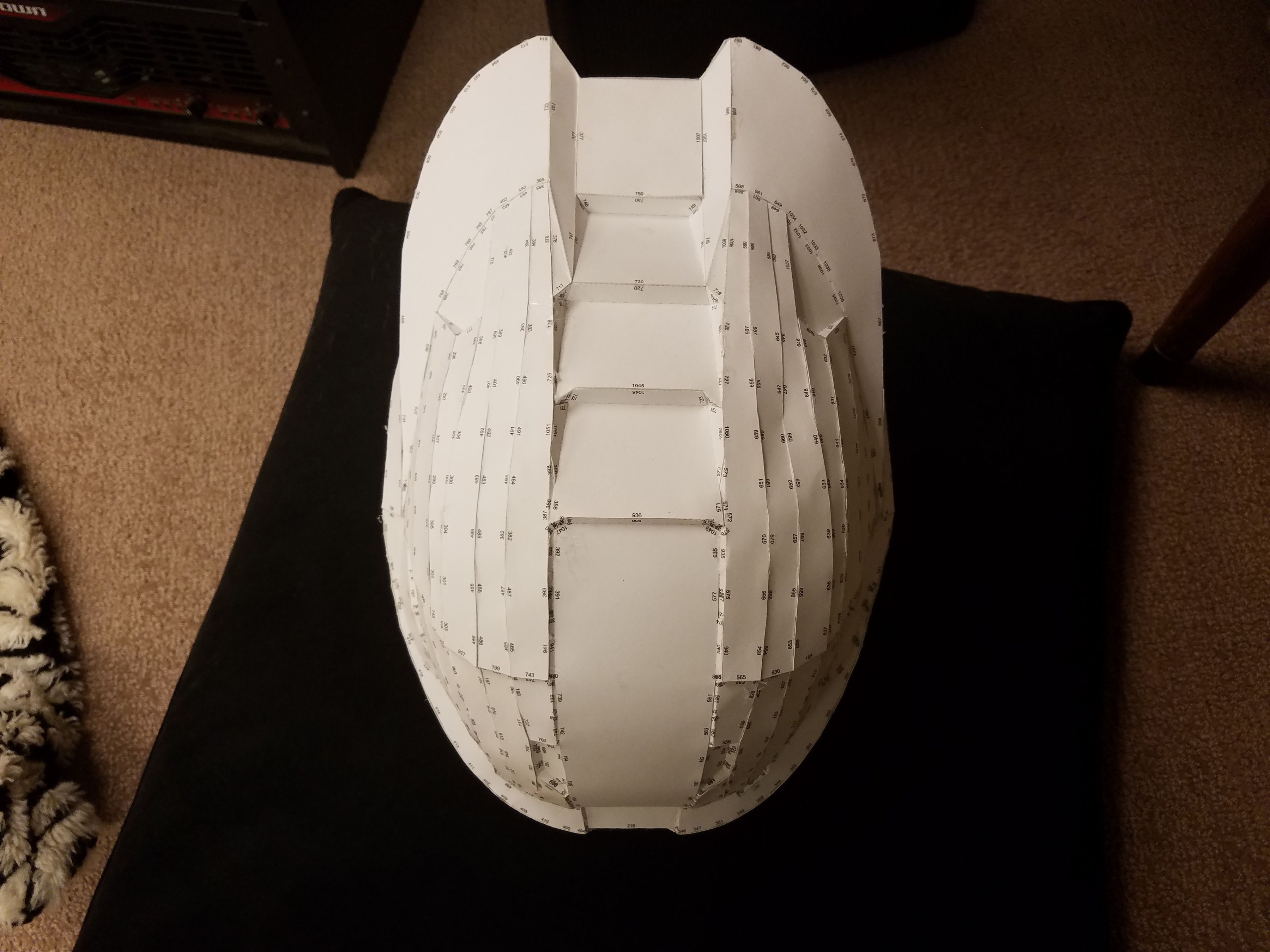

Hope everyone is having a great first day of Autumn. This is my first time posting, but I've been an on-and-off reader for a few years now and have a pep build to show and wanted to ask some questions I hope to find answers to. First off, here is my best pepakura work so far: a Mk. VI helmet build that I am hoping to complete in time for Halloween this year.

I think it came out pretty well! Before I move on to the next steps I have a few questions...

I've read all the sticky posts and tutorials I could find, but I'm still quite confused and unsure about what the exact order of steps are once I am done with the pep work. It seems like every tutorial I find is either incomplete or has it's own method of doing things. From what I can gather, the process seems to be as follows:

1) Pep work (done)

2) Gather materials (resin, body filler, brushes, respirator, gloves, goggles, and mixing containers)

3) Resin the outside (?)

4) Resin the inside (?)

...and then everything gets sort of confusing, with body filler on the outside (??) and fiberglassing the inside (??), and spot putty, etc...

It's all very confusing, and it seems like a lot of the links in the stickys are outdated, dead links, or only explain one step in the overall process without much indication about what the order of the steps are. If someone could lay out the process, step by step, in order from start to finish (meaning a complete helmet that looks finished), I would greatly appreciate it. I would like to finish this helmet so that I can wear it for Halloween and any help I can get is greatly appreciated. Hope you all like the helmet so far! I look forward to your feedback and advice!

Hope everyone is having a great first day of Autumn. This is my first time posting, but I've been an on-and-off reader for a few years now and have a pep build to show and wanted to ask some questions I hope to find answers to. First off, here is my best pepakura work so far: a Mk. VI helmet build that I am hoping to complete in time for Halloween this year.

I think it came out pretty well! Before I move on to the next steps I have a few questions...

I've read all the sticky posts and tutorials I could find, but I'm still quite confused and unsure about what the exact order of steps are once I am done with the pep work. It seems like every tutorial I find is either incomplete or has it's own method of doing things. From what I can gather, the process seems to be as follows:

1) Pep work (done)

2) Gather materials (resin, body filler, brushes, respirator, gloves, goggles, and mixing containers)

3) Resin the outside (?)

4) Resin the inside (?)

...and then everything gets sort of confusing, with body filler on the outside (??) and fiberglassing the inside (??), and spot putty, etc...

It's all very confusing, and it seems like a lot of the links in the stickys are outdated, dead links, or only explain one step in the overall process without much indication about what the order of the steps are. If someone could lay out the process, step by step, in order from start to finish (meaning a complete helmet that looks finished), I would greatly appreciate it. I would like to finish this helmet so that I can wear it for Halloween and any help I can get is greatly appreciated. Hope you all like the helmet so far! I look forward to your feedback and advice!