Gwaar

New Member

Hello 405th members!

This is my first post, i have not built anything yet but i am gathering supplies for an ODST build. I am a brand new member but i have over a decade of auto body and aviation experience.

I believe i have found an excellent solution for sealing EVA foam to last for a long time if not permanently. This is a product used to treat aircraft fabric used in the covering of small aircraft fuselage, wings, and control surfaces. This is your base layer before you apply your UV aluminum coat and paint.

POLY BRUSH!

"Poly Brush is a pink translucent, 1 part air drying resin used for the first 2 or 3 coats to penetrate and seal the fabric weave and assure good adhesion. Also used to attach the finishing tapes and reinforcing patches. Brush on initial coat thinned 3:1 with reducer. Subsequent coats are thinned 3:1 with reducer and applied with a spray gun to avoid brush marks & cut application time." (It can be thinned with Methyl Ethel Ketone (MEK) or their own proprietary thinner.)

WARNING*-The following was done at work in a rush and force cured with a heat gun. Your results will be much better while following the proper cure timeline.

In the above picture i just brushed one thin coat to check the chemical resistance of the EVA to the poly brush. In that test it held up perfectly.

In the above picture here i applied two coats.(Don't mind my finger prints i was at work so i was moving quickly to test the product). Here i brushed the POLY BRUSH on to make a thick coat to see how it would level and how well it would adhere to the EVA. It will NOT come off. POLY BRUSH doesn't cure to a hard surface hence it isn't great to sand but it can be done with wet paper and 600 grit. But, that "soft" cure give it great flexibility. Also, when applied properly it will self level into a perfect substrate to accept primer and paint.

(This is a rough coat. If you were to spray it on with a HVLP gun you would get an excellent uniform coat which is self leveling.)

In the above image here i applied some rattle can sand able auto primer to the POLY BRUSH. Again i force cured just to test and roughly sanded it smooth and it gives you a great flat substrate which has bonded excellently to the POLY BRUSH. This was tested again for flexibility and with the thin coat of primer and the POLY BRUSH it will not crack or smudge of de-bond. The POLY BRUSH also seeps into the foam and i think it will add a small bit of structure to the surface of the product after a full cure.

This is an aviation product but it is cheap!!!!! Around 28$ a Quart 93$ a gallon but a little goes a LONG way once you reduce it. You can find it for sale online all over the place.

I believe this will ensure your EVA pieces will last for a very long time. It will require more experimentation before i would suggest diving into it but once i get started on my build i am going to coat my first section of EVA armor in this before paint and i will post about that in the coming weeks.

I'm better at giving tutorials in person instead of online so i apologize in advance if this post doesn't help. Please ask questions i'm happy to help, and i have quite a bit of experience in automotive paint, refinishing, and aircraft refinishing and restoration.

THANKS FOR READING i hope this helps and becomes a real solution to long lasting EVA armor paint!

This is my first post, i have not built anything yet but i am gathering supplies for an ODST build. I am a brand new member but i have over a decade of auto body and aviation experience.

I believe i have found an excellent solution for sealing EVA foam to last for a long time if not permanently. This is a product used to treat aircraft fabric used in the covering of small aircraft fuselage, wings, and control surfaces. This is your base layer before you apply your UV aluminum coat and paint.

POLY BRUSH!

"Poly Brush is a pink translucent, 1 part air drying resin used for the first 2 or 3 coats to penetrate and seal the fabric weave and assure good adhesion. Also used to attach the finishing tapes and reinforcing patches. Brush on initial coat thinned 3:1 with reducer. Subsequent coats are thinned 3:1 with reducer and applied with a spray gun to avoid brush marks & cut application time." (It can be thinned with Methyl Ethel Ketone (MEK) or their own proprietary thinner.)

WARNING*-The following was done at work in a rush and force cured with a heat gun. Your results will be much better while following the proper cure timeline.

In the above picture i just brushed one thin coat to check the chemical resistance of the EVA to the poly brush. In that test it held up perfectly.

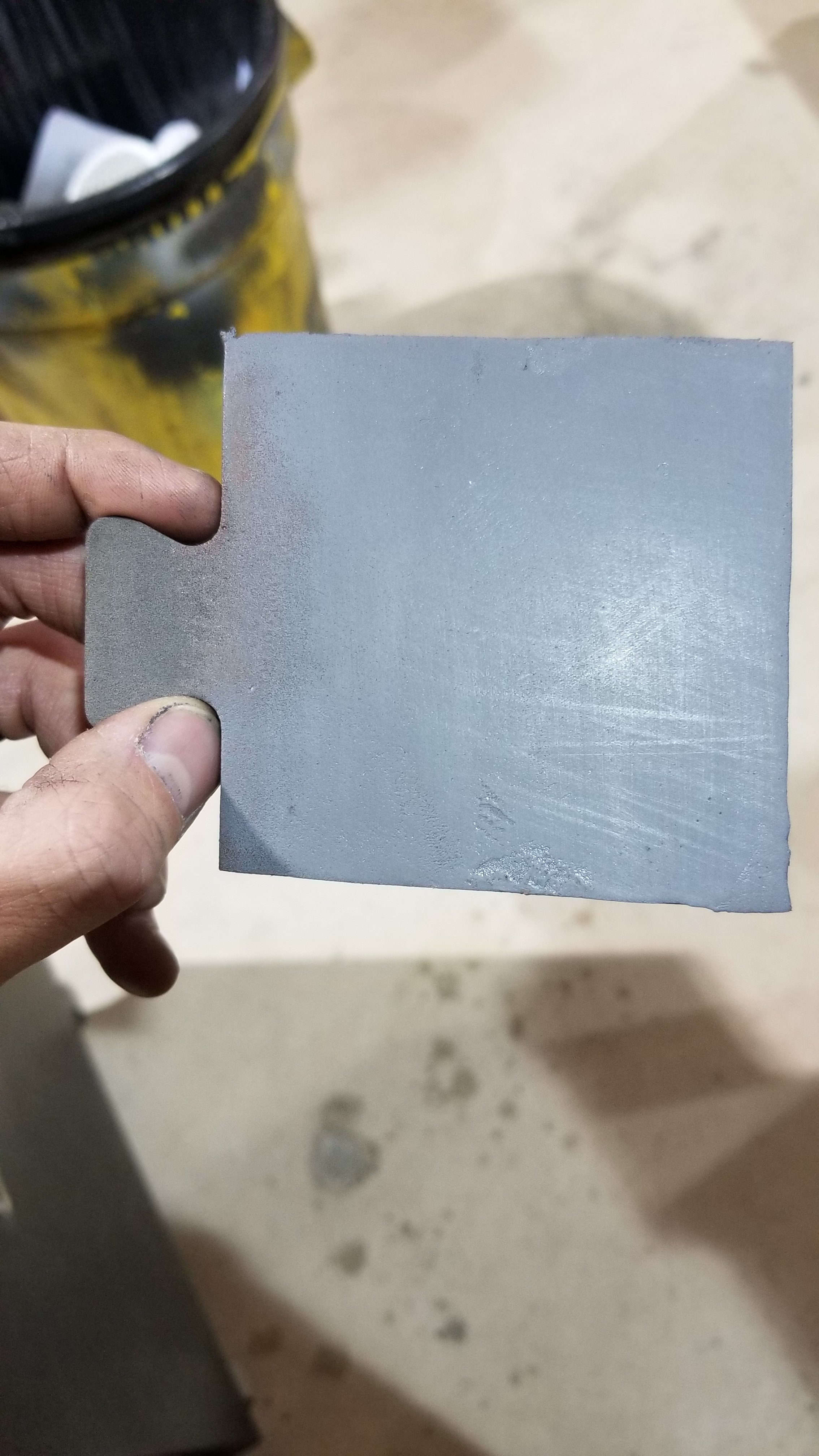

In the above picture here i applied two coats.(Don't mind my finger prints i was at work so i was moving quickly to test the product). Here i brushed the POLY BRUSH on to make a thick coat to see how it would level and how well it would adhere to the EVA. It will NOT come off. POLY BRUSH doesn't cure to a hard surface hence it isn't great to sand but it can be done with wet paper and 600 grit. But, that "soft" cure give it great flexibility. Also, when applied properly it will self level into a perfect substrate to accept primer and paint.

(This is a rough coat. If you were to spray it on with a HVLP gun you would get an excellent uniform coat which is self leveling.)

In the above image here i applied some rattle can sand able auto primer to the POLY BRUSH. Again i force cured just to test and roughly sanded it smooth and it gives you a great flat substrate which has bonded excellently to the POLY BRUSH. This was tested again for flexibility and with the thin coat of primer and the POLY BRUSH it will not crack or smudge of de-bond. The POLY BRUSH also seeps into the foam and i think it will add a small bit of structure to the surface of the product after a full cure.

This is an aviation product but it is cheap!!!!! Around 28$ a Quart 93$ a gallon but a little goes a LONG way once you reduce it. You can find it for sale online all over the place.

I believe this will ensure your EVA pieces will last for a very long time. It will require more experimentation before i would suggest diving into it but once i get started on my build i am going to coat my first section of EVA armor in this before paint and i will post about that in the coming weeks.

I'm better at giving tutorials in person instead of online so i apologize in advance if this post doesn't help. Please ask questions i'm happy to help, and i have quite a bit of experience in automotive paint, refinishing, and aircraft refinishing and restoration.

THANKS FOR READING i hope this helps and becomes a real solution to long lasting EVA armor paint!