Looking forward to seeing the progress!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam ODST: Version 1 was okay. Now for Version 2

- Thread starter PaiganBoi

- Start date

- Status

- Not open for further replies.

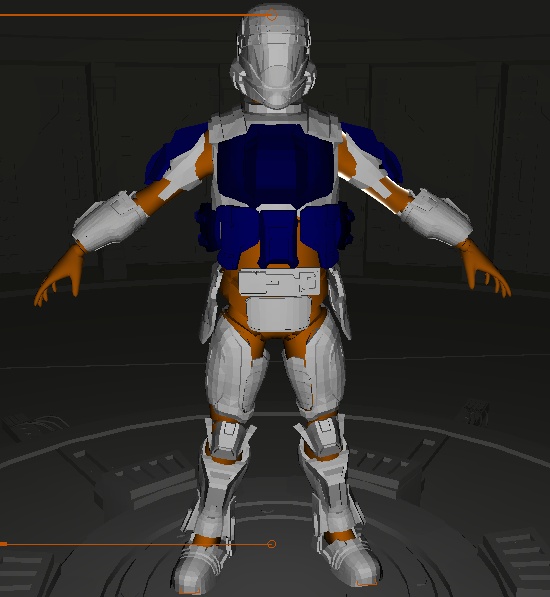

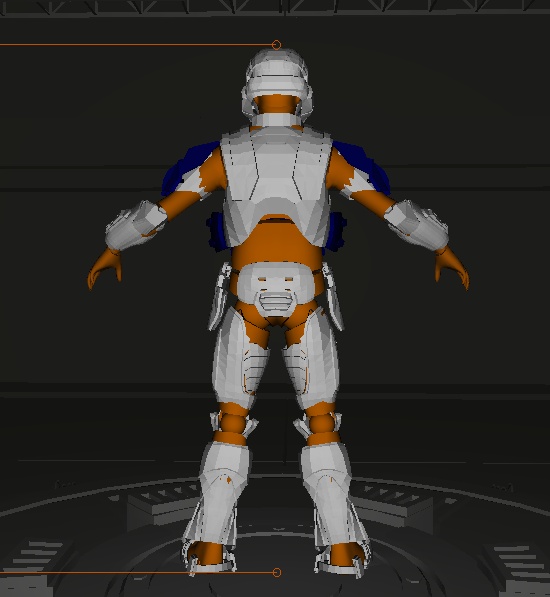

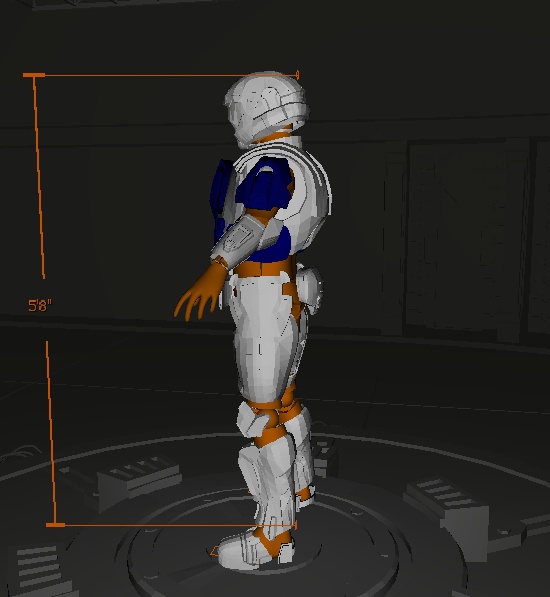

Foam file tweeking in Armorsmith. I still have some more fine tuning to do before I start printing the templates. I need to figure out how to use the non uniform scaling tool thingy.

The shins/knees were already redone last year. Everything else has been rescaled.

Too bad there isn't a file for the hand plates on the gloves. Will have to freehand that one like I did the first time.

The shins/knees were already redone last year. Everything else has been rescaled.

Too bad there isn't a file for the hand plates on the gloves. Will have to freehand that one like I did the first time.

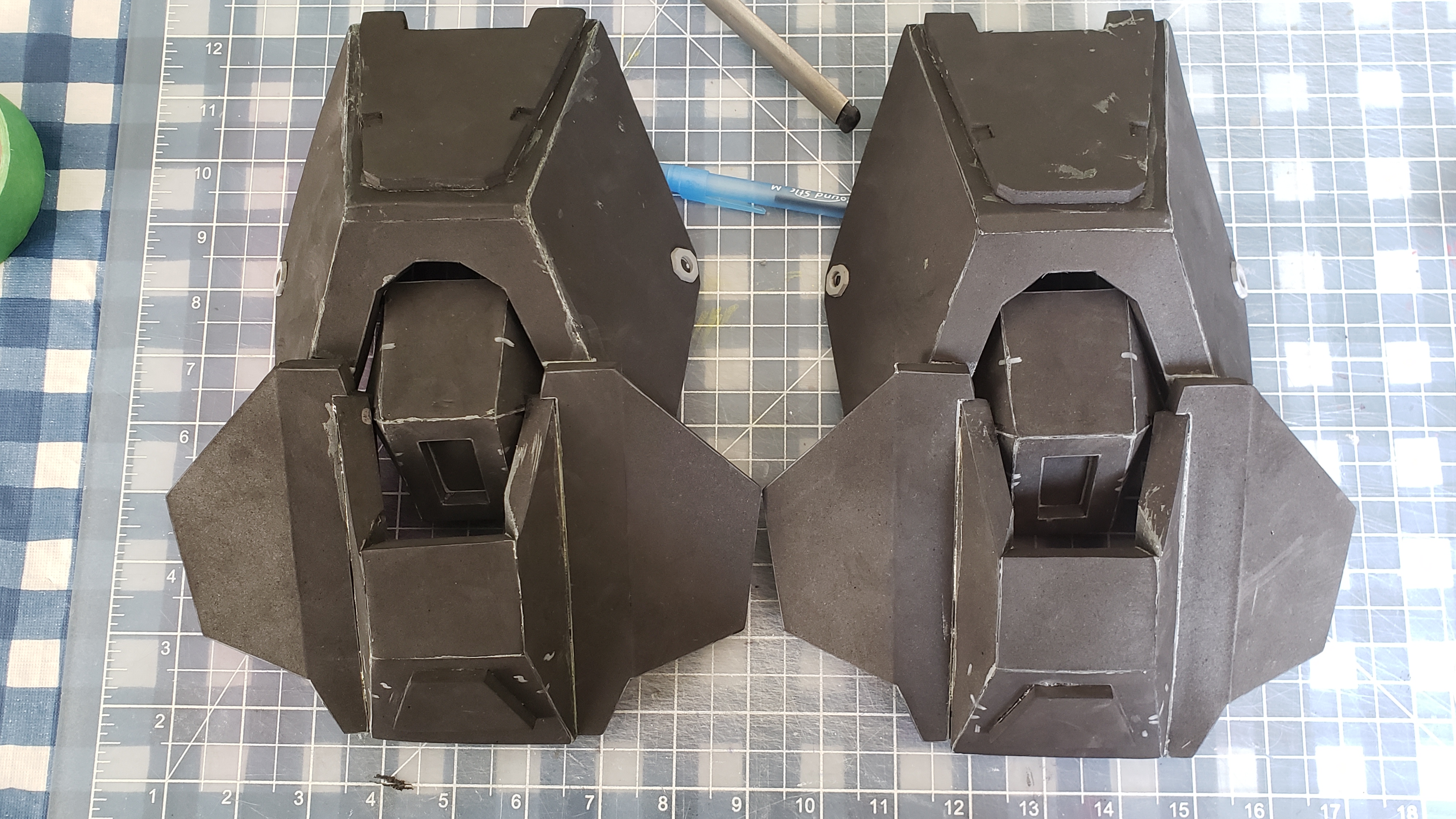

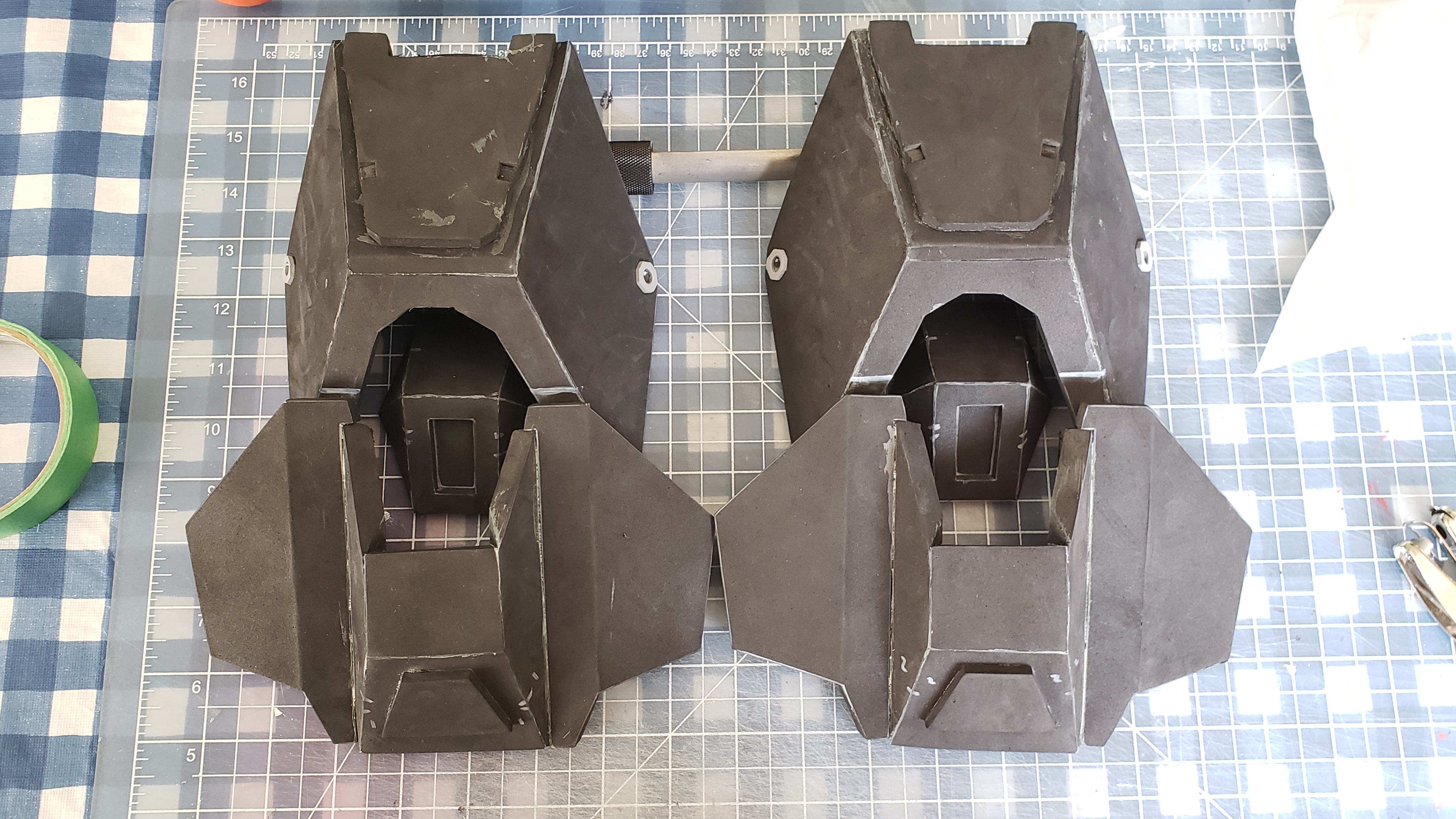

Late night post. Both thighs are done!

Two annoying thing popped up though....

There is a bloody piece missing on both of them!! At first I thought I had missed a piece when I was cutting the templates. It turns out that the missing piece is actually missing from the foam converted file. No biggie to fix this.

The second problem is whats really annoying me.

Here's the inner thigh part for the left leg. I made it all nice and what not....

Guess what? It doesn't even fit!! The shape of the inner thigh is completely off!!

Ugh!

I'm will have to make one up myself.

Two annoying thing popped up though....

There is a bloody piece missing on both of them!! At first I thought I had missed a piece when I was cutting the templates. It turns out that the missing piece is actually missing from the foam converted file. No biggie to fix this.

The second problem is whats really annoying me.

Here's the inner thigh part for the left leg. I made it all nice and what not....

Guess what? It doesn't even fit!! The shape of the inner thigh is completely off!!

Ugh!

I'm will have to make one up myself.

- Member DIN

- S434

I remember having to rig it to fit. Was not funLate night post. Both thighs are done!View attachment 287468

Two annoying thing popped up though....

View attachment 287466

There is a bloody piece missing on both of them!! At first I thought I had missed a piece when I was cutting the templates. It turns out that the missing piece is actually missing from the foam converted file. No biggie to fix this.

The second problem is whats really annoying me.

View attachment 287467

Here's the inner thigh part for the left leg. I made it all nice and what not....

Guess what? It doesn't even fit!! The shape of the inner thigh is completely off!!

View attachment 287469

View attachment 287470

Ugh!

I'm will have to make one up myself.

Yeah. I will most likely wrap my leg with cling wrap and Duct tape then while wearing the thigh have my wife trace out the inner thigh shape and make my own templates from that.I remember having to rig it to fit. Was not fun

Mad respect for the detail you're putting into this foam build. Looking great!

Hey WinterHuntsman! Just saw your post of your shoulders. Talk about coincidence that you posted yours just before I posted my shoulders.

All I have to do is mount them onto my shoulder bases.

All I have to do is mount them onto my shoulder bases.

WinterHuntsman

Member

Those shoulders look very nice! Anything you have been doing to get them to look that clean with the cuts, angles, and glue?

Biggest thing is using a higher quality foam. I splurged and bought some HD foam.Those shoulders look very nice! Anything you have been doing to get them to look that clean with the cuts, angles, and glue?

Foam and a sharp knife makes doe some really clean bevels.

Also when doing bevels I put some painters tape as a guide to keep me straight. Then some clean up with a rotary tool.

Alright... Dilemmas... For those you who have been following this thread, I want to ask your opinion. As you know my rebuild started last year with the shins. Those were made of reliable puzzle mat foam from Walmart. Now the recent armour parts that were completed were made with HD Foam by Lumin's Workshop bought from Arda Wigs Canada.

The question I am asking is.... Should I build the shins/greaves again? This time with the HD foam to match the rest of the rebuild.

The question I am asking is.... Should I build the shins/greaves again? This time with the HD foam to match the rest of the rebuild.

What would be causing you from holding back and pondering over it? If you have doubts, go for it, but if you are happy with what you already have, keep them. It doesnt hurt to make more thoughAlright... Dilemmas... For those you who have been following this thread, I want to ask your opinion. As you know my rebuild started last year with the shins. Those were made of reliable puzzle mat foam from Walmart. Now the recent armour parts that were completed were made with HD Foam by Lumin's Workshop bought from Arda Wigs Canada.

The question I am asking is.... Should I build the shins/greaves again? This time with the HD foam to match the rest of the rebuild.

TurboCharizard

RXO and BCO

Canadian Regiment

405th Regiment Officer

Delta

Community Staff

Stream Team

- Member DIN

- S068

It'll probably be more dent and ding resistant made with HD Foam but then again, it's the shins. Cheap foam getting beat up? BATTLE DAMAGEAlright... Dilemmas... For those you who have been following this thread, I want to ask your opinion. As you know my rebuild started last year with the shins. Those were made of reliable puzzle mat foam from Walmart. Now the recent armour parts that were completed were made with HD Foam by Lumin's Workshop bought from Arda Wigs Canada.

The question I am asking is.... Should I build the shins/greaves again? This time with the HD foam to match the rest of the rebuild.

To tell the truth I just guessed. I knew the angles were between 45 and 90 degrees. So when cutting my bevels one part had a bevel of 45 (roughly 1/4 inch) and then other side I would measure 1/8 inch and it works out.Great work on the shoulders. I'm struggling a bit with my own... any tips for getting the right angles? I've been trying to interpret the edge angles that Armorsmith gives you but it doesn't really make sense to me.

This is looking great man, I'm sorry i was not here early to support! Keep it up and looking forward forward to seeing this progress!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 491

- Replies

- 8

- Views

- 397

- Replies

- 3

- Views

- 354

- Replies

- 1

- Views

- 117

Similar threads

- Replies

- 1

- Views

- 117