I know this is not dead on game accurate but is designed as a base which can be easily added to and modified depending on the amount of detail and realism you are attempting to attain.

Ok guys… There have been a lot of questions about how I made my foam Reach boots. Since my boots were scratch made and I had drawn them out as I made them I decided to recreate the templates.. I drew it out how I had done it and then I ran into a problem. For the life of me I could not figure out how to put the hand drawn templates online to be able to adjust the size easily and maintain the scale.

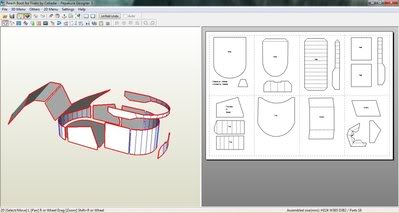

So I decided to teach myself blender in one day. YEA RIGHT!! Unfortunately I am old and when I was in college things were drawn out on a drafting table and with drafting tools and the only graphics programs were Autocad and Drafixcad (first generation) which I did have experience with and still had a copy of but alas they will not run on modern machines. So after that kicked my butt I began looking around for something else that I could pick up quickly. I downloaded Google Sketch up and was able to pick up the basics of it pretty quick.

Made a 3d model… transferred it to Pepakura… Unfolded it and then made a boot from the file.. I had to go back and forth and make several adjustments along the way to make it work the way I wanted it to. Now I know the model is basic and rough but it will get the job done. So without further a due here is the pep file and the tutorial to go with how I made it

and the file:

http://www.4shared.com/file/tk_xitUL/Reach_Boot_for_Foam_by_Callada.html

Now the file is sized for US Men’s size 11 – 12.. If you have to adjust it use the width line to adjust the size larger or smaller.

First I assembled my basic tools for working with foam..

1. Hot glue gun

2. Extra glue

3. Hot knife

4. Sharpie (I like silver)

5. Scissors

6. Straight edge

7. Desk top sharpening stone (for exacto blade)

8. Holder for hot knife / soldering gun

9. Tape (not pictured)

10. Foam mat (for this I am using ½” foam from walmart.. I prefer the 3/8” that I purchase from Amazon but I am currently out so this will have to do. Keep in mind that different thickness of the foam will affect the fit of the pieces. The file was made for ½” foam. If you use thinner foam you may have to trim some from the heel and toe for a proper fit. If you use thicker foam you may have to add some to the heel and toe for a proper fit.)

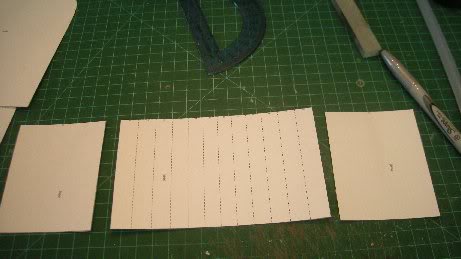

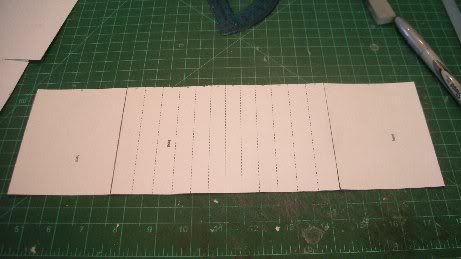

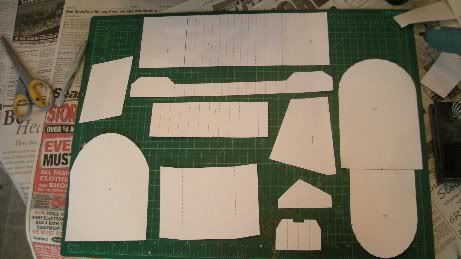

Now after printing the file I cut out all pieces.. I then proceeded to tape pieces together that I knew I would use to make larger pieces for the foam.

Tape the 2 pieces to the sole together, tape the 3 pieces of the heel together, tape the 2 pieces of the toe together, and tape the 2 detail pieces of the heel together.

Once I had all the pieces cut out and taped together I got ready to get down to business.

Time to turn this into a boot…

After cutting out the sole, heel, toe sides and toe it is time to assemble the basic boot.

First I am going to start at the heel. Attach the heel to the back of the sole starting at the bottom forward corner and work around the back to the other side. Flex the foam first so that it can easily bend around the curve of the heel. Glue in place.

Moving forward on the boot prepare the toe side pieces. You will want to bevel the front (forward) side of the toe side to help with getting a smooth seam and allow for the bend.

Glue the toe Side into place aligning with the sides of the sole.

Glue the toe piece to the front of the toe side piece and then hold a strong bend in the toe to help prepare it for the bend of the toe.

Ok guys… There have been a lot of questions about how I made my foam Reach boots. Since my boots were scratch made and I had drawn them out as I made them I decided to recreate the templates.. I drew it out how I had done it and then I ran into a problem. For the life of me I could not figure out how to put the hand drawn templates online to be able to adjust the size easily and maintain the scale.

So I decided to teach myself blender in one day. YEA RIGHT!! Unfortunately I am old and when I was in college things were drawn out on a drafting table and with drafting tools and the only graphics programs were Autocad and Drafixcad (first generation) which I did have experience with and still had a copy of but alas they will not run on modern machines. So after that kicked my butt I began looking around for something else that I could pick up quickly. I downloaded Google Sketch up and was able to pick up the basics of it pretty quick.

Made a 3d model… transferred it to Pepakura… Unfolded it and then made a boot from the file.. I had to go back and forth and make several adjustments along the way to make it work the way I wanted it to. Now I know the model is basic and rough but it will get the job done. So without further a due here is the pep file and the tutorial to go with how I made it

and the file:

http://www.4shared.com/file/tk_xitUL/Reach_Boot_for_Foam_by_Callada.html

Now the file is sized for US Men’s size 11 – 12.. If you have to adjust it use the width line to adjust the size larger or smaller.

First I assembled my basic tools for working with foam..

1. Hot glue gun

2. Extra glue

3. Hot knife

4. Sharpie (I like silver)

5. Scissors

6. Straight edge

7. Desk top sharpening stone (for exacto blade)

8. Holder for hot knife / soldering gun

9. Tape (not pictured)

10. Foam mat (for this I am using ½” foam from walmart.. I prefer the 3/8” that I purchase from Amazon but I am currently out so this will have to do. Keep in mind that different thickness of the foam will affect the fit of the pieces. The file was made for ½” foam. If you use thinner foam you may have to trim some from the heel and toe for a proper fit. If you use thicker foam you may have to add some to the heel and toe for a proper fit.)

Now after printing the file I cut out all pieces.. I then proceeded to tape pieces together that I knew I would use to make larger pieces for the foam.

Tape the 2 pieces to the sole together, tape the 3 pieces of the heel together, tape the 2 pieces of the toe together, and tape the 2 detail pieces of the heel together.

Once I had all the pieces cut out and taped together I got ready to get down to business.

Time to turn this into a boot…

After cutting out the sole, heel, toe sides and toe it is time to assemble the basic boot.

First I am going to start at the heel. Attach the heel to the back of the sole starting at the bottom forward corner and work around the back to the other side. Flex the foam first so that it can easily bend around the curve of the heel. Glue in place.

Moving forward on the boot prepare the toe side pieces. You will want to bevel the front (forward) side of the toe side to help with getting a smooth seam and allow for the bend.

Glue the toe Side into place aligning with the sides of the sole.

Glue the toe piece to the front of the toe side piece and then hold a strong bend in the toe to help prepare it for the bend of the toe.