Alright, technically this isn't my build - I'm helping my kid build one for a school book report project. The plan is for the report to be on the hull of the ship itself. We're going to attach the paragraphs as removable panels so afterwards he can have the ship hanging in his bedroom. Long story short, this is on a tight schedule - roughly 4 weeks, so not going for complete accuracy here.

I couldn't find any Pillar Of Autumn files available but CPO mendez was gracious in providing one of his models for the project. Unfortunately this model has a lot of bad polygons in it and is needing a lot of cleanup work. While doing this I am also improving its details here and there when the edits aren't too difficult. The model's scale is huge - nearly 6 feet long! Although very tempting to make it full size, it's just not practical so we're building it at 50% scale, which makes it just over 2 feet long. At first this was going to be a Pepakura project but we just don't have the time to make the model edits, unfold it, clean up the junk Tamasoft exports with DXF files, and do all the folding and gluing - so this has ended up being a 3D printed model. The model file will not be provided for download (at least not just now).

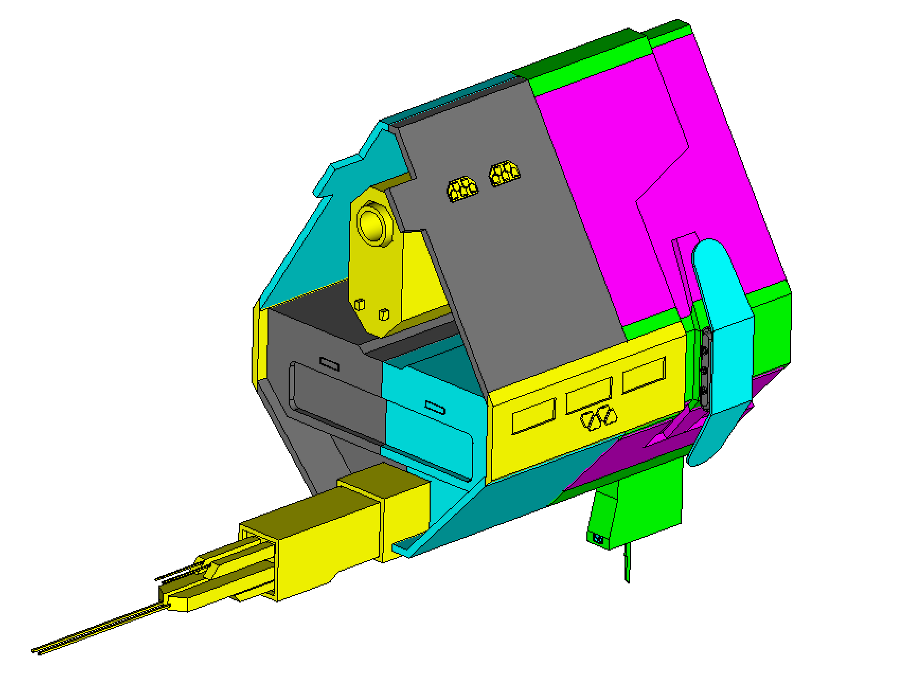

So like I said, the first step is getting that model cleaned up. I've got the forward section done (minus the lower turret - all the turrets might end up having to be put on later after we get the ship back home from school). To save on filament and overall weight I've hollowed out the model, and in order to print the parts without any steep overhangs needing supports plus keep the parts small so they print quicker I've divided the ship into parts similar to a model kit. Each part is represented by a different color in the image below:

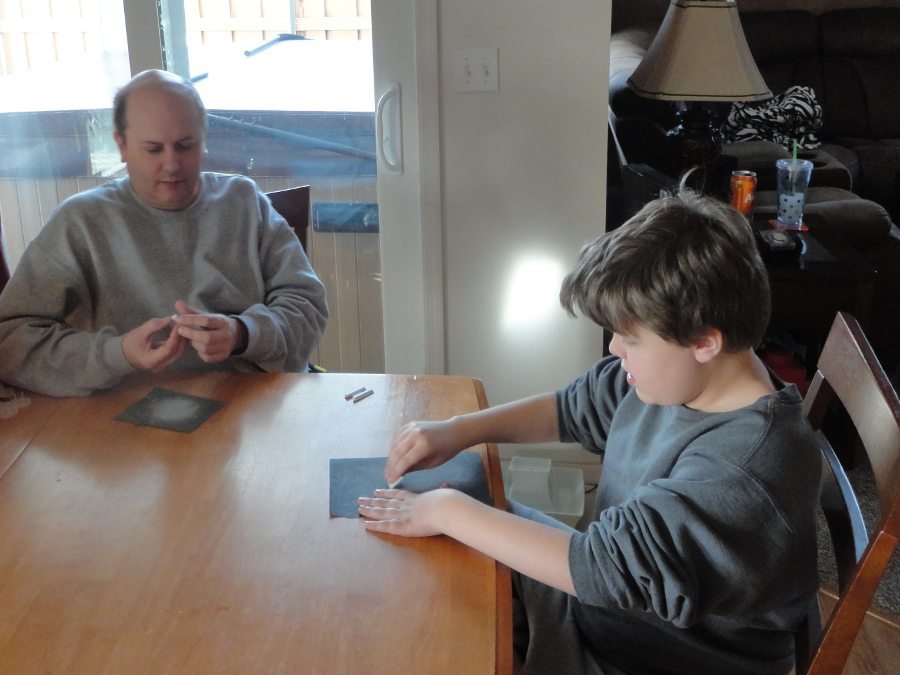

As you can see, still a long ways to go on converting the model. The first few parts are already printed and here we are with sandpaper getting them prepped:

I'll get a close-up photo of the printed parts when more of them are ready and before they start getting glued together. Still working at trying to figure out this whole 3D printing stuff. Hoping the build turns out looking good.

I couldn't find any Pillar Of Autumn files available but CPO mendez was gracious in providing one of his models for the project. Unfortunately this model has a lot of bad polygons in it and is needing a lot of cleanup work. While doing this I am also improving its details here and there when the edits aren't too difficult. The model's scale is huge - nearly 6 feet long! Although very tempting to make it full size, it's just not practical so we're building it at 50% scale, which makes it just over 2 feet long. At first this was going to be a Pepakura project but we just don't have the time to make the model edits, unfold it, clean up the junk Tamasoft exports with DXF files, and do all the folding and gluing - so this has ended up being a 3D printed model. The model file will not be provided for download (at least not just now).

So like I said, the first step is getting that model cleaned up. I've got the forward section done (minus the lower turret - all the turrets might end up having to be put on later after we get the ship back home from school). To save on filament and overall weight I've hollowed out the model, and in order to print the parts without any steep overhangs needing supports plus keep the parts small so they print quicker I've divided the ship into parts similar to a model kit. Each part is represented by a different color in the image below:

As you can see, still a long ways to go on converting the model. The first few parts are already printed and here we are with sandpaper getting them prepped:

I'll get a close-up photo of the printed parts when more of them are ready and before they start getting glued together. Still working at trying to figure out this whole 3D printing stuff. Hoping the build turns out looking good.

Last edited: