RELLIK NISSASSA

Jr Member

What's up 405th?

I hope that you find this useful and inspiring as you journey through your Halo armor experience, and mad props to all on the 405th. We all belong to a great thing here.

BREAKDOWN OF ARMOR SPECIFICATIONS:

Armor Class: Mark VI

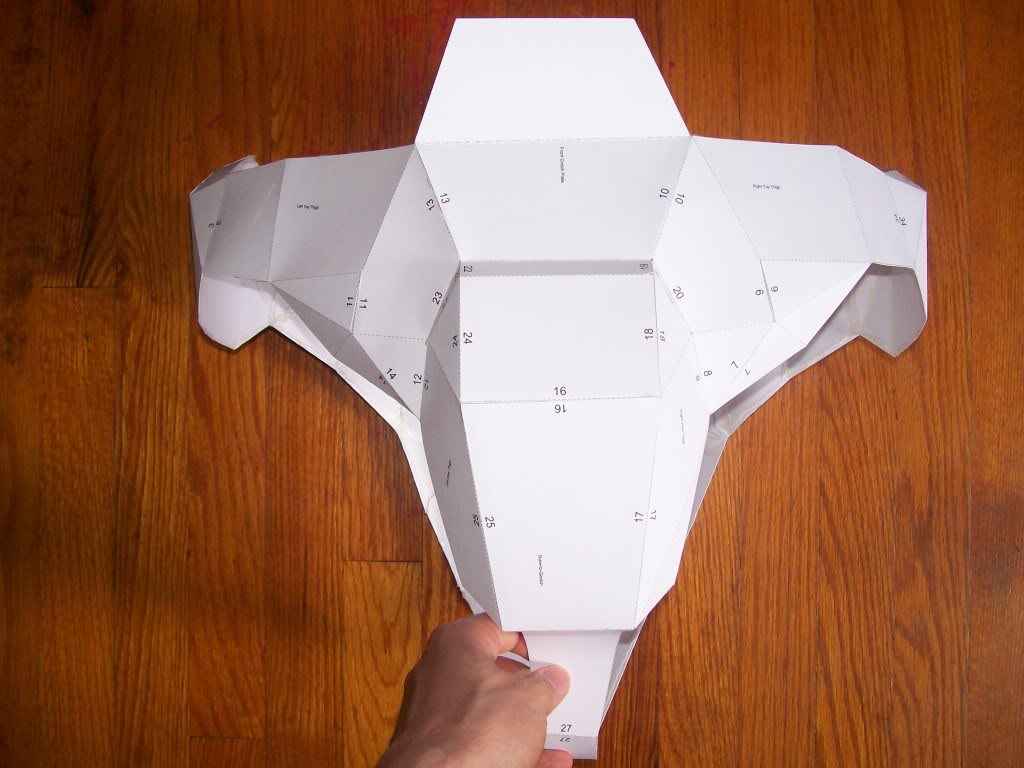

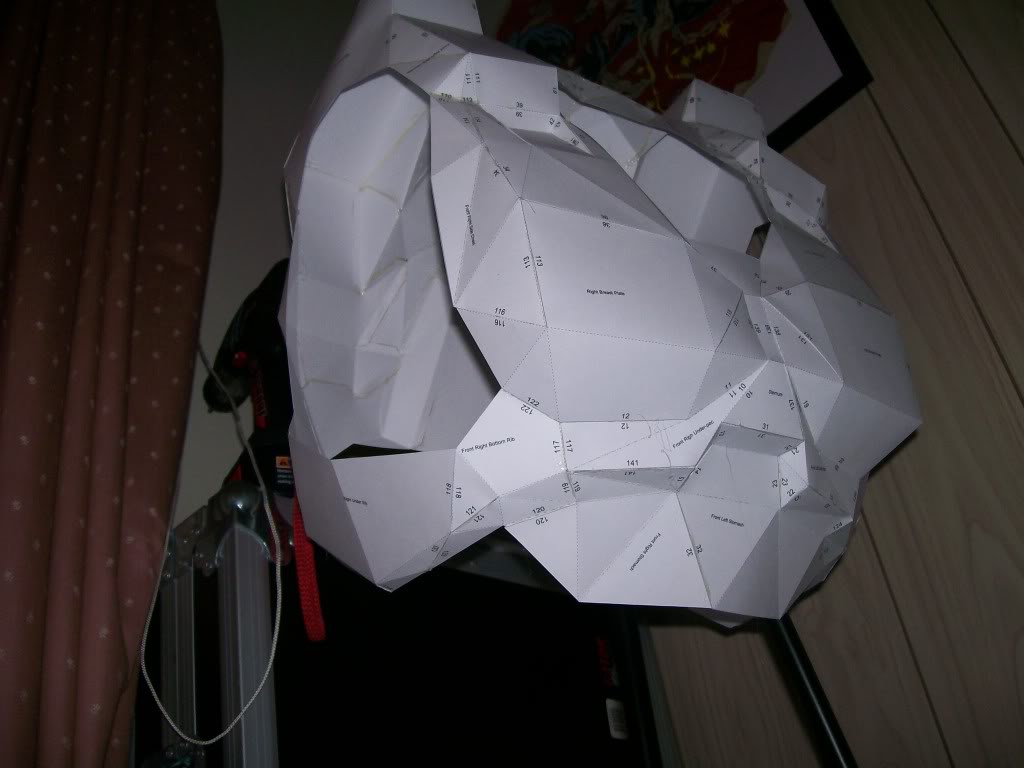

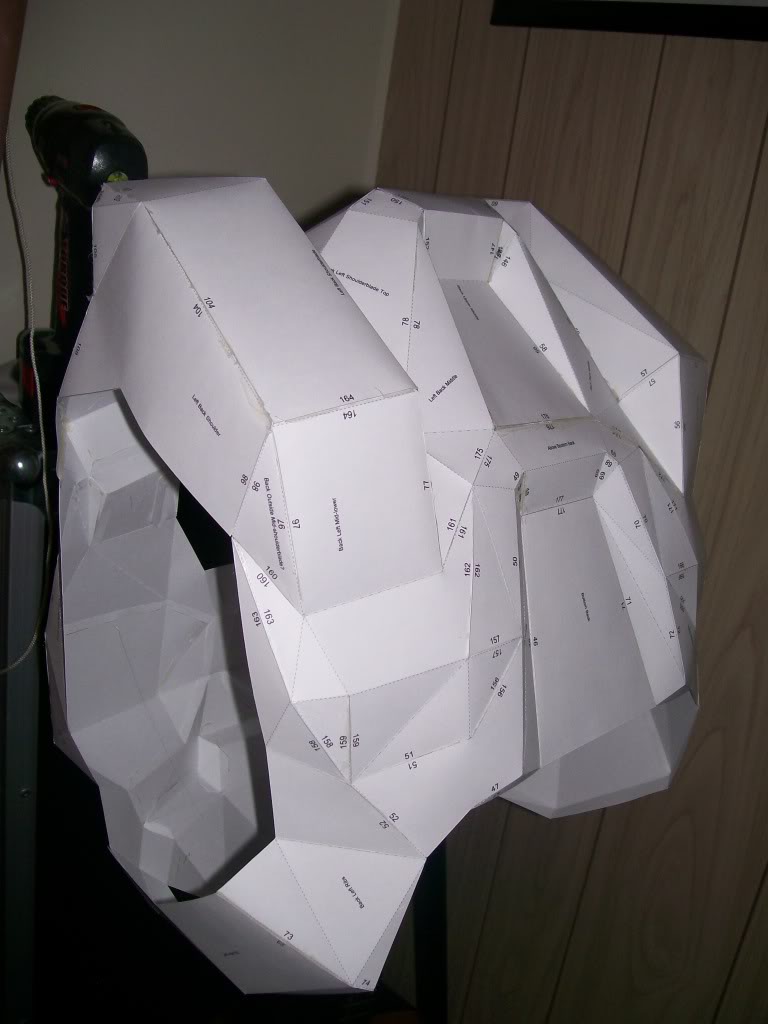

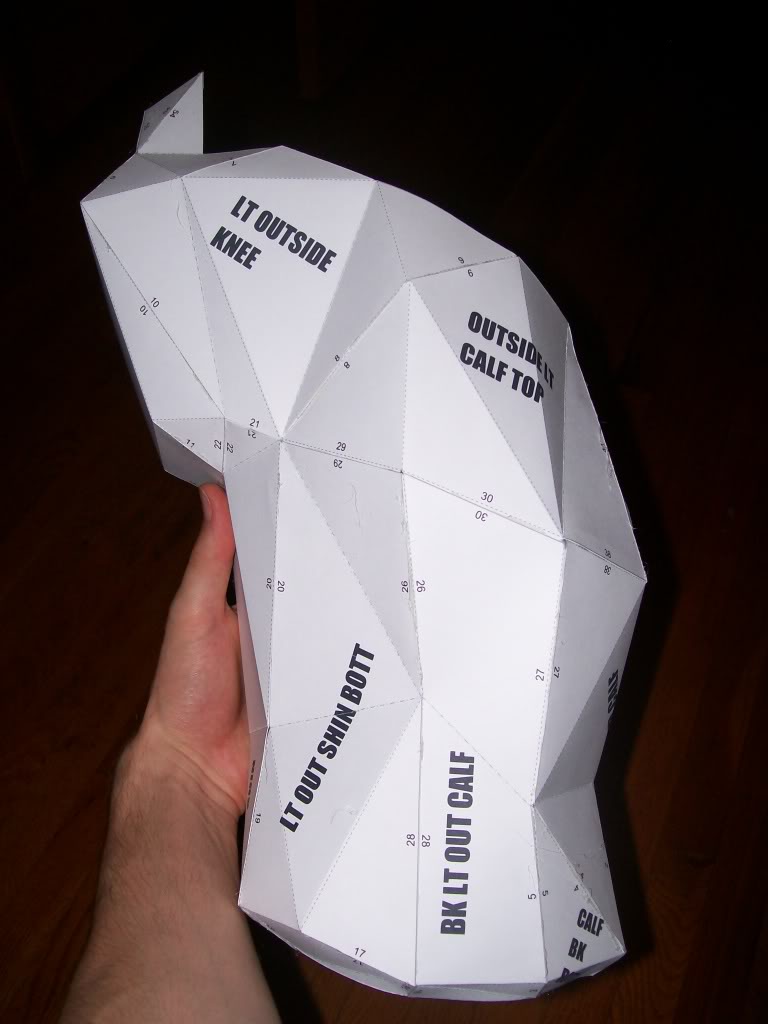

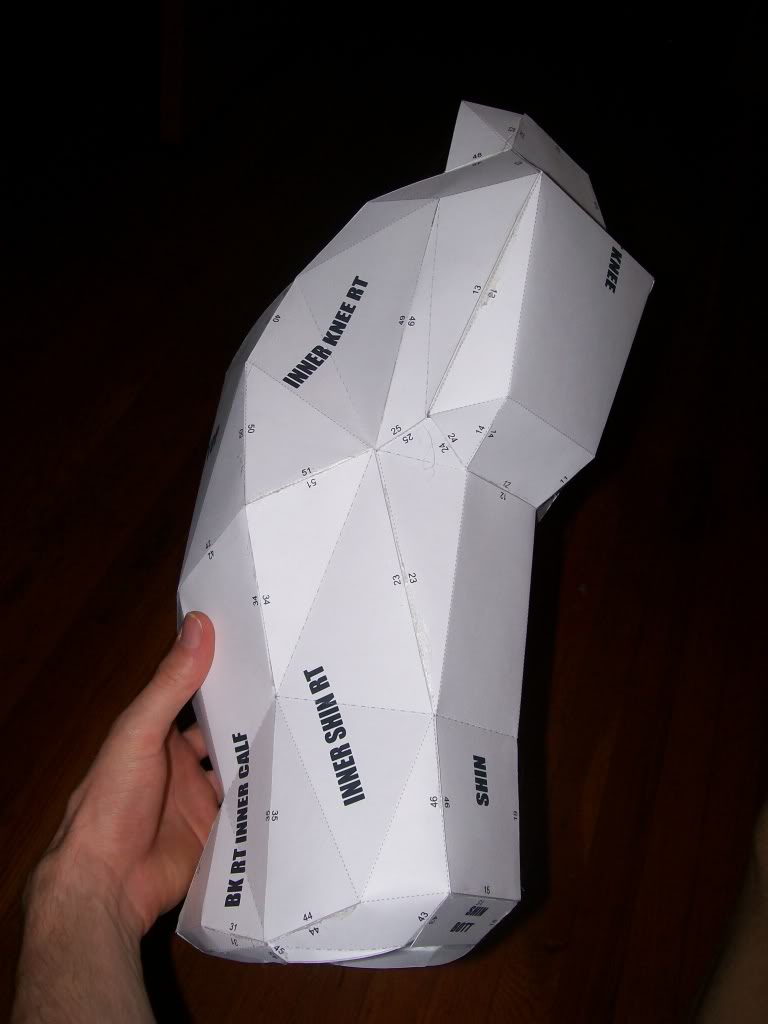

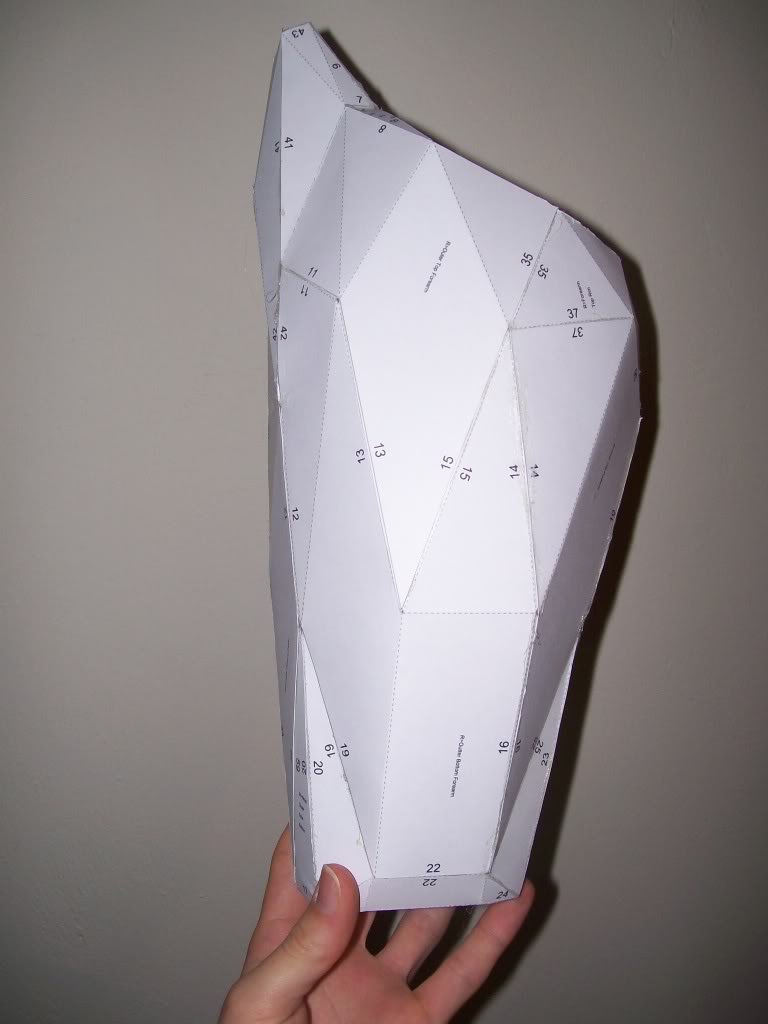

Armor Base: Pepakura

File Types: Frizzle Fry -full body// Flying Squirrel-HD Helmet

TOOLS LIST:

Paper Used: Georgia Pacifc White Card Stock// 110 lb Weight, 150 count

Adhesive Agent: Hot Glue

Glue Gun: Obvious

Cutting Device: Large X-ACTO knife

Cutting Board: Smooth finished scrap plywood

Straight Edge: Hard Platice, thich square (aprox 6-8 inches in length)

Scotch Tape: Used as a temp. holding agent for complicated bends

Red Rock Gloves: Used durign hot glue application. Able to hold parts and glue in place while experiencing no burns or discomfort.

Great Freakin Music to keep me going: Very important

EXTRA X-ACTO BLADES

EXTRA GLUE STICKS

possibly EXTRA CARD STOCK (this is for when you cut a flap off a piece, or have to cut a piece off you project and reprint the part)

PLAN OF ACTION:

To complete all peps before continuing onto the resin stage.

Once pepped, all parts will be coated in Smooth Cast 320 to solidify the base.

Parts then detailed, re-coated, and silicone/rubber molded.

PURPOSE OF ARMOR:

To have a functional suit to wear, ski in, play paintball, and rock out in.

GOAL:

To have the entire suit finished by 10/30/09. My real goal is to creatan armor so thich and durable that it will withstand any beating. I want this stuff to be ass thich and strong as a bike helmet, not just another pretty costume.

We're talking real, functional armor.

So.... on with the pictures.

I will not post a tutorial or video tutorials unless requested. so comment and reply away.

NOTE TO SELF: DO YOUR HELMET LAST!!! Look at everybody who has done their helmet first. They never seem to finish any other parts. I suppose they become so satisfied that the hlemet is finished and they have something cool to wear, so they give up on the other stuff. Pep all first, and save the best for last.

Don't forget to thank God for this forum and all who post on it.

I hope that you find this useful and inspiring as you journey through your Halo armor experience, and mad props to all on the 405th. We all belong to a great thing here.

BREAKDOWN OF ARMOR SPECIFICATIONS:

Armor Class: Mark VI

Armor Base: Pepakura

File Types: Frizzle Fry -full body// Flying Squirrel-HD Helmet

TOOLS LIST:

Paper Used: Georgia Pacifc White Card Stock// 110 lb Weight, 150 count

Adhesive Agent: Hot Glue

Glue Gun: Obvious

Cutting Device: Large X-ACTO knife

Cutting Board: Smooth finished scrap plywood

Straight Edge: Hard Platice, thich square (aprox 6-8 inches in length)

Scotch Tape: Used as a temp. holding agent for complicated bends

Red Rock Gloves: Used durign hot glue application. Able to hold parts and glue in place while experiencing no burns or discomfort.

Great Freakin Music to keep me going: Very important

EXTRA X-ACTO BLADES

EXTRA GLUE STICKS

possibly EXTRA CARD STOCK (this is for when you cut a flap off a piece, or have to cut a piece off you project and reprint the part)

PLAN OF ACTION:

To complete all peps before continuing onto the resin stage.

Once pepped, all parts will be coated in Smooth Cast 320 to solidify the base.

Parts then detailed, re-coated, and silicone/rubber molded.

PURPOSE OF ARMOR:

To have a functional suit to wear, ski in, play paintball, and rock out in.

GOAL:

To have the entire suit finished by 10/30/09. My real goal is to creatan armor so thich and durable that it will withstand any beating. I want this stuff to be ass thich and strong as a bike helmet, not just another pretty costume.

We're talking real, functional armor.

So.... on with the pictures.

I will not post a tutorial or video tutorials unless requested. so comment and reply away.

NOTE TO SELF: DO YOUR HELMET LAST!!! Look at everybody who has done their helmet first. They never seem to finish any other parts. I suppose they become so satisfied that the hlemet is finished and they have something cool to wear, so they give up on the other stuff. Pep all first, and save the best for last.

Don't forget to thank God for this forum and all who post on it.