This is the first time i have ever started a topic on any forum in my life, please be kind.

I have read a few posts saying how there parent would not allow them to use the resin. So I have tried to think of a way for people to do this. This is what I came up with.

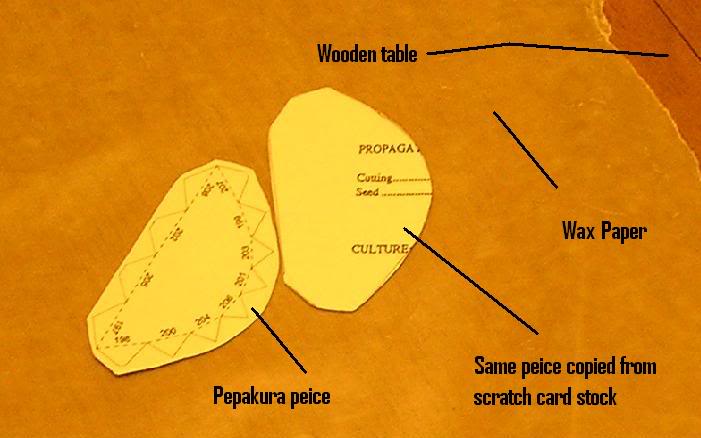

I have cut out the pepakura pieces leaving a small border of paper around as a buffer. Then I placed it on a scrap piece of card stock, and traced it out. Then I placed them both on wax paper.

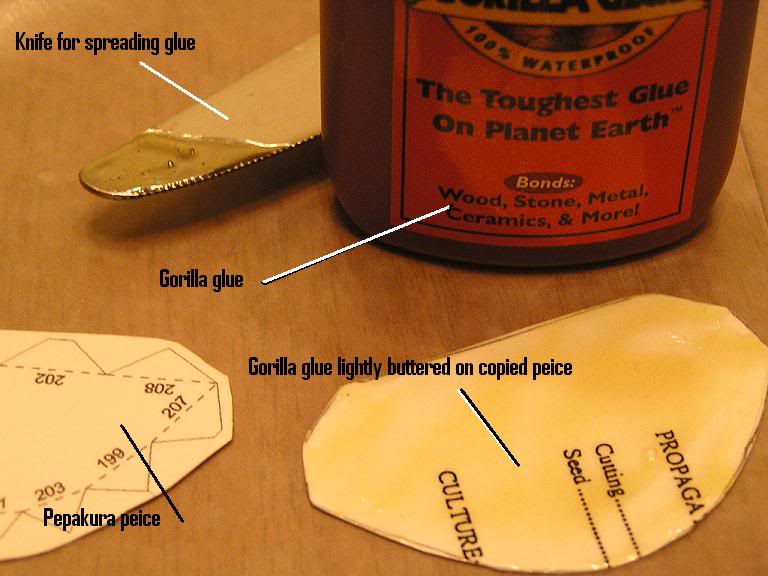

(Please don't use the knife again it is not safe anymore for eating purposes)

Next I used a butter knife and applied a thin layer of gorilla glue to the traced piece.

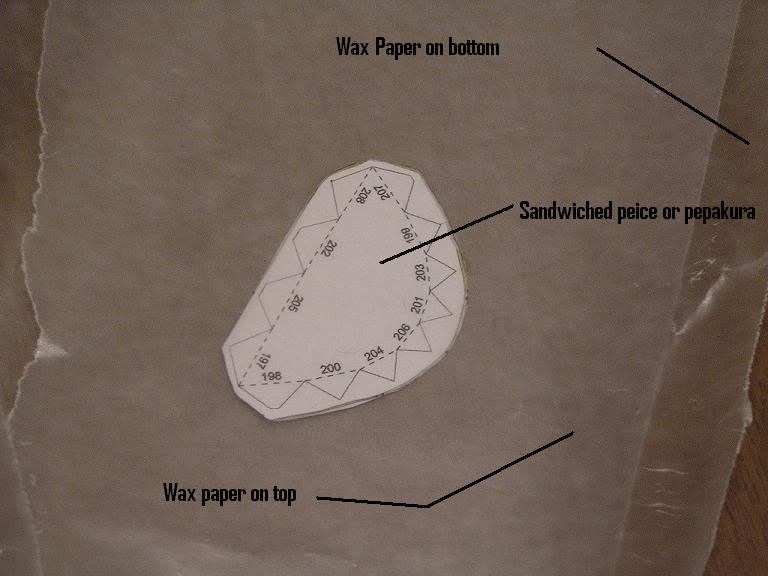

Next I placed another piece of wax paper over so the gorilla glue would not stick to the table.

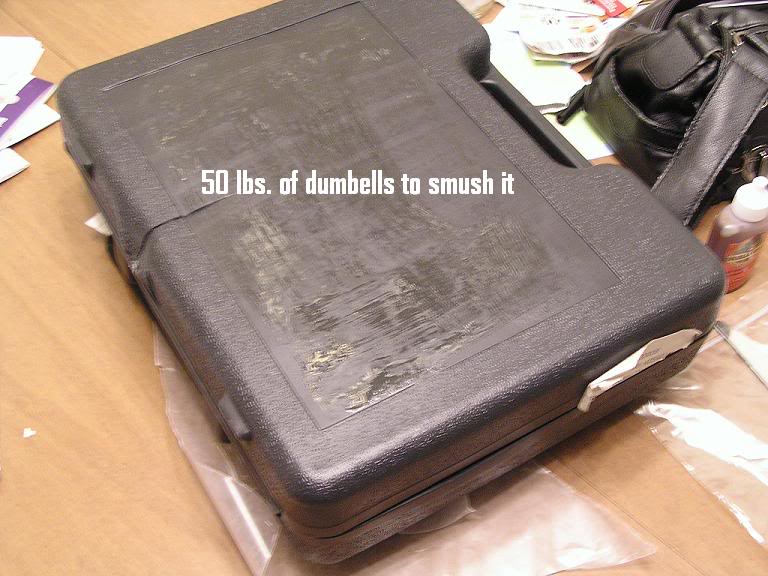

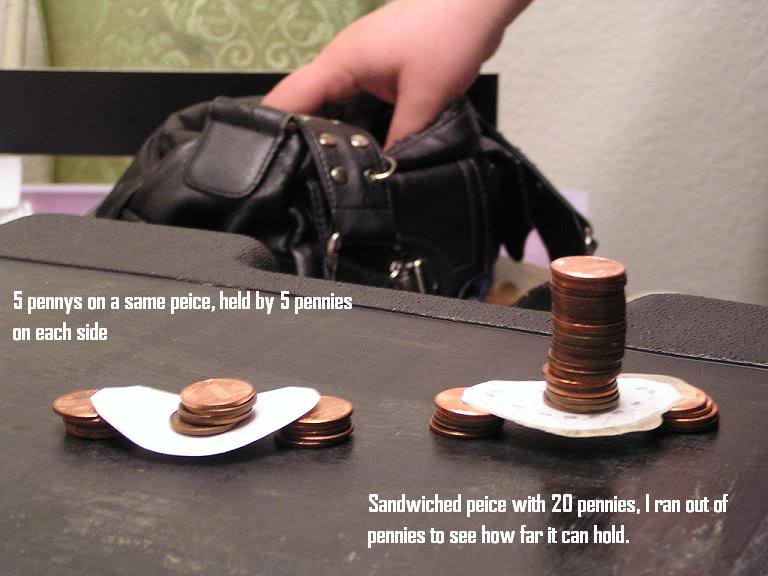

Next I added a nice weight to hold it down to create a tight bond.

Next I have pulled the sandwiched piece out to show you the strength compared to a normal piece of pepakura.

I would have placed more on pennies on it to bend it, but I ran out. The glue hasn't fully cured yet so I will post again when it is. Right now it has the feeling of a thin guitar pick, if that helps any. I will be going to the store today and buy some Elmers fiberglass sheets to see how much more that will alter the pepakura piece. I do not want it to strong, because then I will not be able to give it that little bend during assembly.

I have read a few posts saying how there parent would not allow them to use the resin. So I have tried to think of a way for people to do this. This is what I came up with.

I have cut out the pepakura pieces leaving a small border of paper around as a buffer. Then I placed it on a scrap piece of card stock, and traced it out. Then I placed them both on wax paper.

(Please don't use the knife again it is not safe anymore for eating purposes)

Next I used a butter knife and applied a thin layer of gorilla glue to the traced piece.

Next I placed another piece of wax paper over so the gorilla glue would not stick to the table.

Next I added a nice weight to hold it down to create a tight bond.

Next I have pulled the sandwiched piece out to show you the strength compared to a normal piece of pepakura.

I would have placed more on pennies on it to bend it, but I ran out. The glue hasn't fully cured yet so I will post again when it is. Right now it has the feeling of a thin guitar pick, if that helps any. I will be going to the store today and buy some Elmers fiberglass sheets to see how much more that will alter the pepakura piece. I do not want it to strong, because then I will not be able to give it that little bend during assembly.