spartanx360

Active Member

hi,

i'm going to tell about my CNC build of the magnum from halo reach.

first thing that I did was open an hi-res pepakura of the M6B.

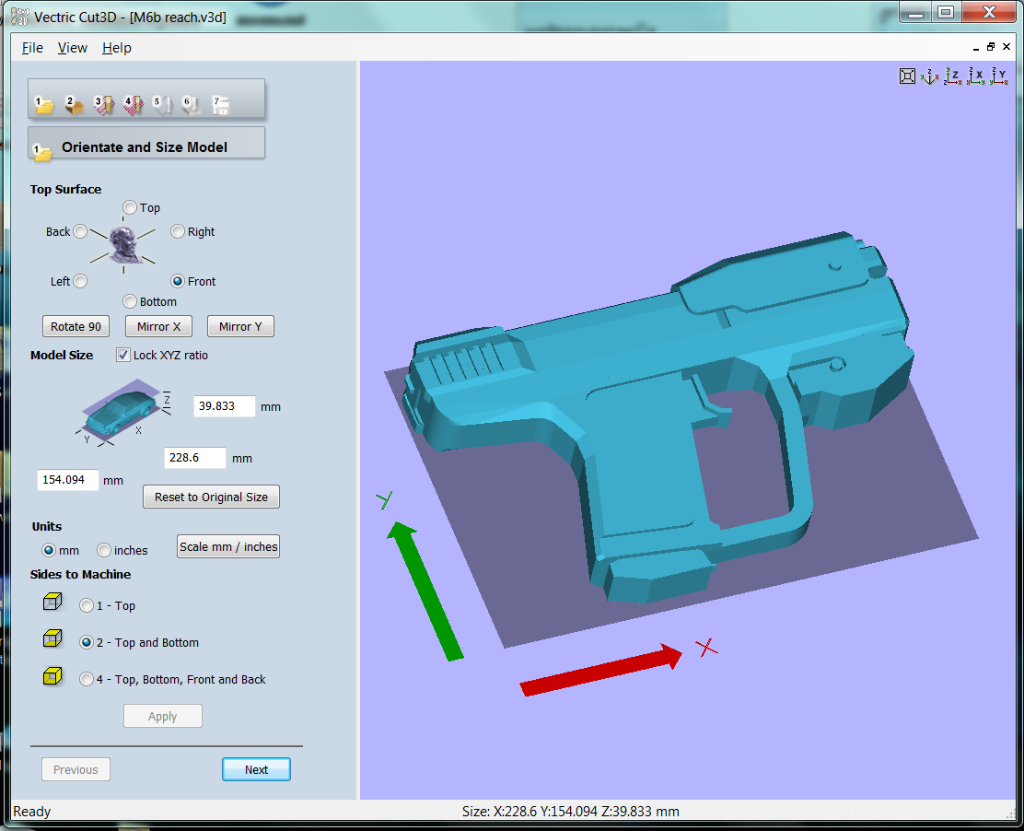

I exported it to an .obj where I could open it in CUT3D

I sliced the magnum in 2 halfs, because my machine can only do 1 side at a time.

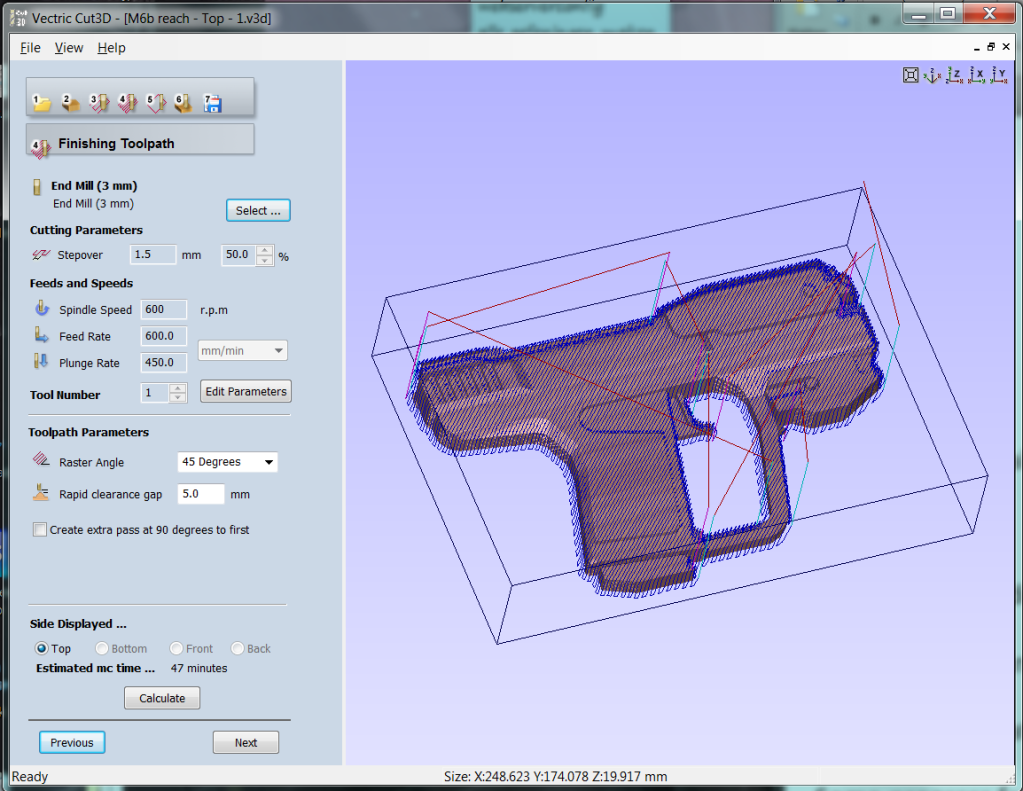

From there I created a path for the cnc machine to cut out the M6B.

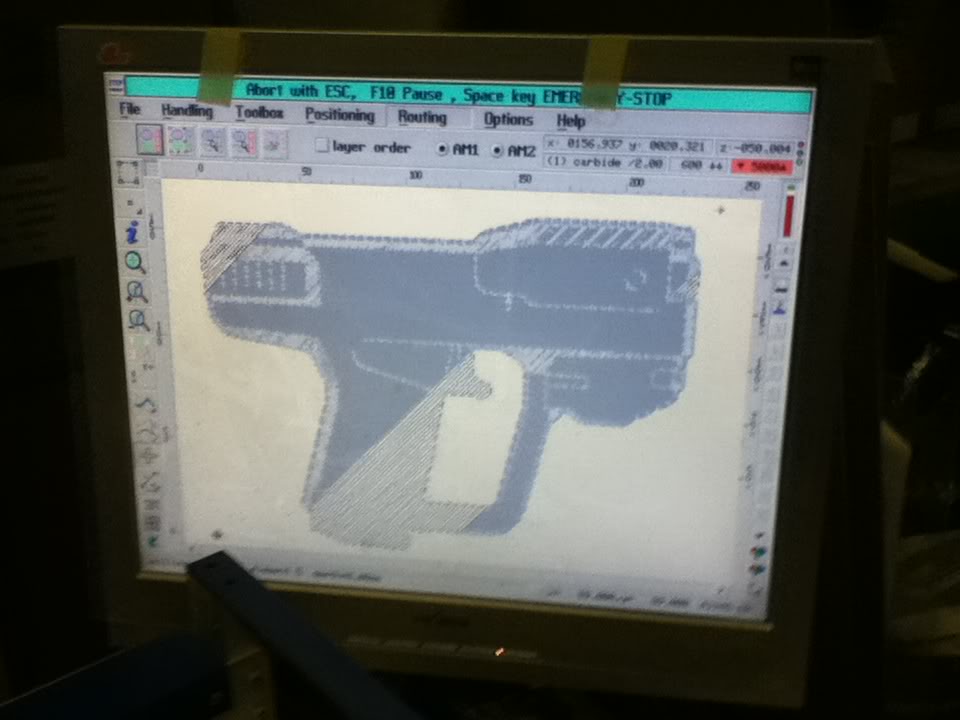

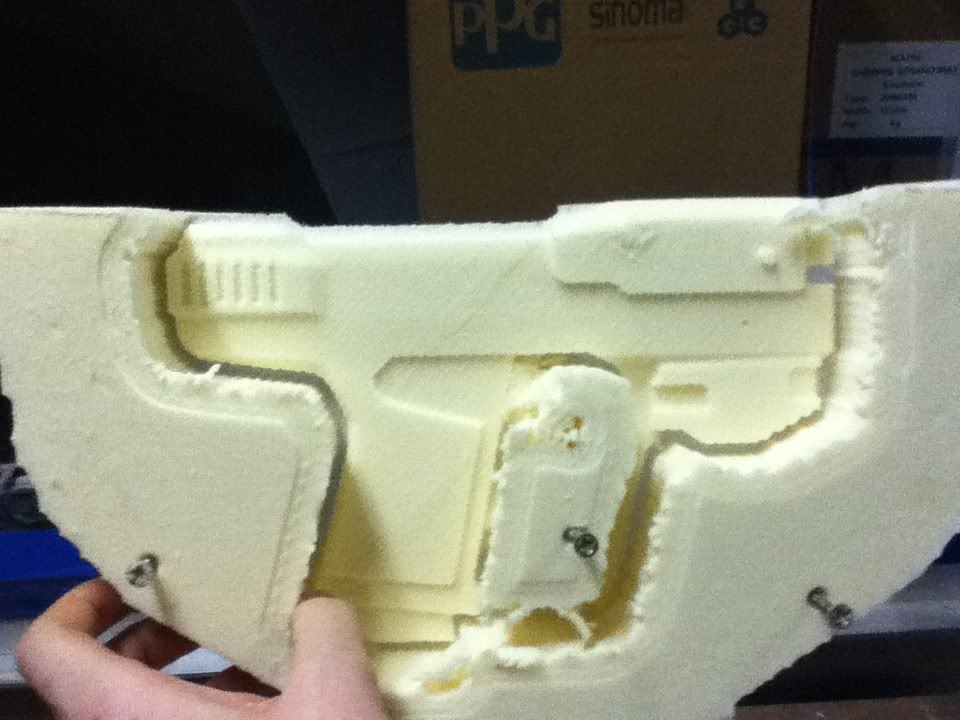

Some progress from the cnc machine

i'm going to tell about my CNC build of the magnum from halo reach.

first thing that I did was open an hi-res pepakura of the M6B.

I exported it to an .obj where I could open it in CUT3D

I sliced the magnum in 2 halfs, because my machine can only do 1 side at a time.

From there I created a path for the cnc machine to cut out the M6B.

Some progress from the cnc machine