AlphaLupi

New Member

Greetings, this is my first time returning to this forum in.. 14 years! I wanted to build Halo armor in the 405th since I was a kid, failing to master Pepakura altogether. Now that I have a Neptune 3 Plus, I think Im ready to get this party started.

I'm attempting to start a Halo 3 marine, using the files provided in the file library.

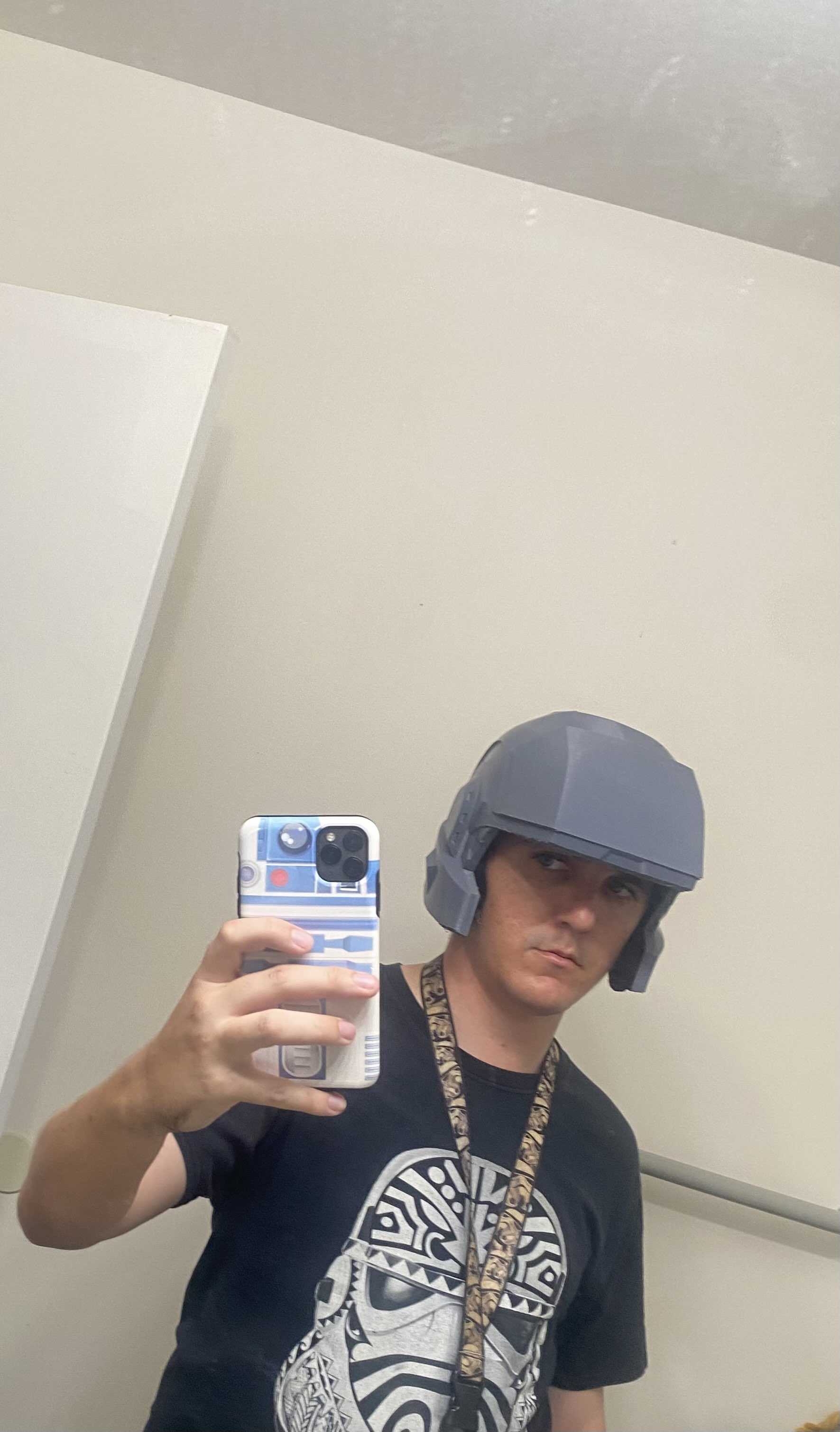

And so the helmet is done printing, after trial and error, and having to reprint this guy from PLA+ to PETG, (I'm new to 3d printing, this is my first helmet ever attempted on the machine)

I just stuffed the sides with foam as a fitting/comfort test. Using extra helmet pads I used for my Scout Trooper helmet (501st)

Next up I'll be printing the shoulders following that the Chest piece. I've already printed one shoulder before in PLA+ but again need to replace with PETG.. But good news its given me somewhat of an idea on sizing.

I've attempted to use Armorsmith for sizing but its now defunct apprently/broken, (at least for me?) until they update the software I'm gonna be eyeing it and trying to measure as good as possible.

I'm also deciding right now what kind of camo I should be using for this build, Ive read the thread suggesting faded New Zealand DPM (Used by WETA Workshops in Halo: Landfall), and British Desert DPM, if you guys have any camo suggestions lmk

British Desert DPM

Faded New Zealand DPM

I also don't know if I should use Wood Filler or Bondo for the helmet, if you guys know which is preferable, I'd like to know which! Oh and sand paper info please, lol, new to this

Thanks for reading, end ted talk. lol

I'm attempting to start a Halo 3 marine, using the files provided in the file library.

And so the helmet is done printing, after trial and error, and having to reprint this guy from PLA+ to PETG, (I'm new to 3d printing, this is my first helmet ever attempted on the machine)

I just stuffed the sides with foam as a fitting/comfort test. Using extra helmet pads I used for my Scout Trooper helmet (501st)

Next up I'll be printing the shoulders following that the Chest piece. I've already printed one shoulder before in PLA+ but again need to replace with PETG.. But good news its given me somewhat of an idea on sizing.

I've attempted to use Armorsmith for sizing but its now defunct apprently/broken, (at least for me?) until they update the software I'm gonna be eyeing it and trying to measure as good as possible.

I'm also deciding right now what kind of camo I should be using for this build, Ive read the thread suggesting faded New Zealand DPM (Used by WETA Workshops in Halo: Landfall), and British Desert DPM, if you guys have any camo suggestions lmk

British Desert DPM

Faded New Zealand DPM

I also don't know if I should use Wood Filler or Bondo for the helmet, if you guys know which is preferable, I'd like to know which! Oh and sand paper info please, lol, new to this

Thanks for reading, end ted talk. lol

Last edited: