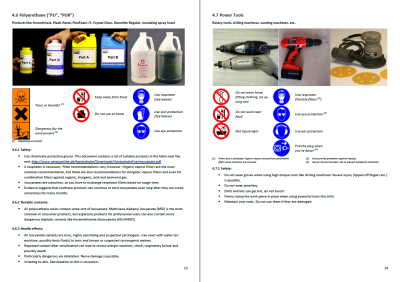

Evidence suggests that urethane products can continue to emit isocyanates even long after they are cured, sometimes for many months.

This is from page 13. Do you have any citations that expand on this? I cannot unfortunately read the German one, despite my account name.

Isocyanates have been a real thorn in my side as far as using Smooth-On products and whether I should worry about long term exposure(the primary use at the moment would be for filling voids in a helmet with Foam-It 10) post-cure.

Tonight I purchased access to "Flexible Polyurethane Foam. I. FTIR Analysis of Residual Isocyanate" which is an article from

Journal of Applied Science, Volume 34, Issue 1, July 1987, Pages: 395–407, K. C. Cole, P. Van Gheluwe, M. J. Hébrard and J. Leroux. This article seems to be cited in a lot of isocyanate research on health effects.

Basically, they used Fourier transform infrared techniques to measure the amount unreacted isocyanate present when cutting them open after they had been left in both dry and humid environments.

The long and short of it was that unreacted isocyanates were present in higher concentrations for a longer time in a dry environment than in a humid environment. Temperature and humidity at foam creation affected the amounts detected, with higher humidities and temperatures leading to less isocyanates being present. The article concludes with:

After a period of approximately 1 week, the residual isocyanate concentration becomes virtually stable. Only severe hydrolytic conditions accelerate the depletion of the remaining isocyanate groups.

which seems pretty hopeful to me.

Now, there are some things that need to be said about the conclusion I am drawing from this. One, they are talking about flexible polyurethane foam and Foam-It 10 is a rigid foam which is ultimately a difference of open cell vs. closed cell foam. I do not know if this affects the speed of outgassing but it seems like closed cell foam would outgas slower. Two, I have no idea how the test foam actually compares to Smooth-On's products, but I am trusting that Smooth-On has done the research and it is as good or better as far as toxic substance presence after cure. Three, there would still be a danger of unreacted isocyanates being released when sanding or cutting into the foam post-cure, especially within that first week to 10 days(this is longest period the study covered).

So, those are some of my thoughts on that particular subject. I hope this was an appropriate thread to expand the discussion on isocyanates. I just want to find the best, safest products to use for myself as well as everyone else. The last thing I would want to see is someone developing asthma or deteriorated lung function due to improper use of products in a hobby.