I'm digging your pepp skills mate. Efforts like these inspire me to start pepp work myself. Keep up the good work!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Halex's MkVI Build (WIP)

- Thread starter Halex

- Start date

- Status

- Not open for further replies.

Thanks Ragnar!Loving your work

I'm sure you can, this was my first try and the amount I've learned along the way is nothing short of amazing. The community here is great, so if you ever have any questions, just ask!This looks fantastic! I hope I can make a build as good as this!

Thanks, Ghost! I kinda miss the pep part, actually. Gives me more incentive to start on another once this is done!I'm digging your pepp skills mate. Efforts like these inspire me to start pepp work myself. Keep up the good work!

--

Another quick update from last evening. Put in way more time than I thought would be necessary on a scratch-built foam ab plate, since I'd somehow forgotten that part so far. The rough upper edge/corner are hidden, but I had to bevel them to fit under the front of the torso without taking away any more of the inside space.

It's not bad, but if I had more time before Dragon*Con I'd either re-do it or make a few small changes. It's attached directly to the front of the torso, and fits pretty well.

The torso overall is a little small, but manageable. Now that I have the dimensions of it finalized with the addition of the ab plate, I can continue work tonight on the undersuit. The plan is to have each section of it buckle to the harness (not shown) in the front and back, then the two parts fasten together on the sides below the arms. I'll use either buckles, velcro, or both. It would probably be simpler to just fasten it directly to the harness, but I'd like to be able to reuse this for multiple armor sets so I'm avoiding attaching anything directly to it. Instead I'll add many, many attachment points so I can connect whatever I need to the same harness.

Now I just need to convince my team lead to let me work from home tomorrow...

More updates to come, and I appreciate all the support from you guys on this last sprint for Dragon*Con! As always, any comments/constructive criticism are welcome!

Last day to do work! I'm sure I'll be up late tonight trying to finish everything, but here's what I did last night (and this morning until 4 am).

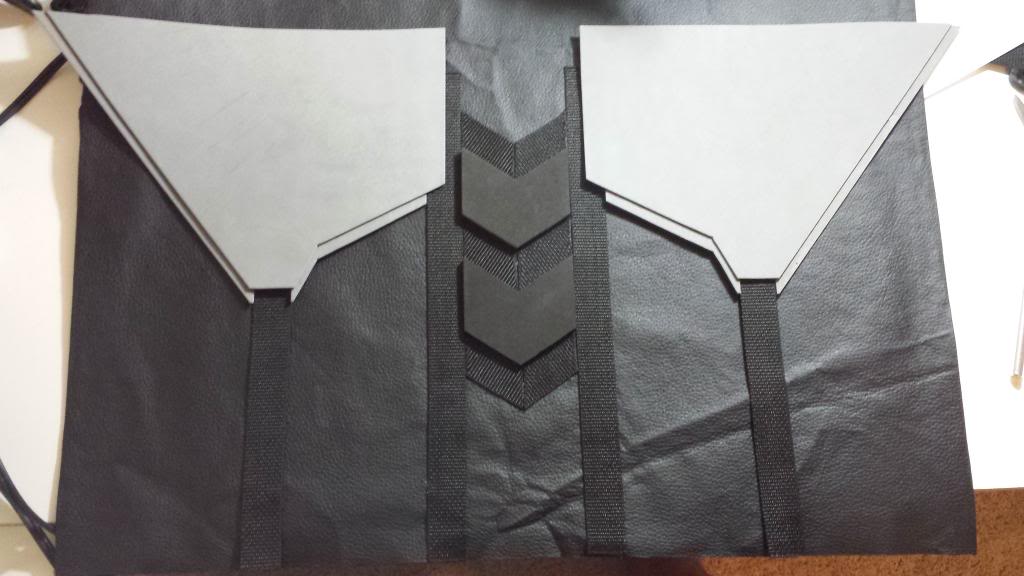

Starting with a basic vinyl piece, after about four hours I had the basics laid out.

I knew I'd never be able to perfectly align and seal the seams in the two 2mm gray pieces, so I decided to go with an overlap. Seemed to work out pretty well and gave me an easy way to hide the strap, too. Trying foam to start with, but if it doesn't hold up I may convert to more vinyl in the 11th hour. Everything is held together by hot glue at this point. So much hot glue... just silly, ludicrous amounts of hot glue.

Four more hours later I was essentially done.

Buckles installed and ready, the strap on the female end velcros to the felt backing on the inside to be adjustable. There's a small slit in the fold that allows the strap to be fed through to hide the extra webbing. The foam parts are all plasti-dipped and trimmed to fit the front.

I was happy with how it turned out until I went to try it on under the torso... and I couldn't get the torso to close. I'll be removing some material from the inside of it tonight to get it to fit, and if that still isn't enough I'll convert the large foam undersuit pieces to vinyl.

Still have to do boots and lights and a neck seal and... jeez this list is too long. Time to get back to work!

Starting with a basic vinyl piece, after about four hours I had the basics laid out.

I knew I'd never be able to perfectly align and seal the seams in the two 2mm gray pieces, so I decided to go with an overlap. Seemed to work out pretty well and gave me an easy way to hide the strap, too. Trying foam to start with, but if it doesn't hold up I may convert to more vinyl in the 11th hour. Everything is held together by hot glue at this point. So much hot glue... just silly, ludicrous amounts of hot glue.

Four more hours later I was essentially done.

Buckles installed and ready, the strap on the female end velcros to the felt backing on the inside to be adjustable. There's a small slit in the fold that allows the strap to be fed through to hide the extra webbing. The foam parts are all plasti-dipped and trimmed to fit the front.

I was happy with how it turned out until I went to try it on under the torso... and I couldn't get the torso to close. I'll be removing some material from the inside of it tonight to get it to fit, and if that still isn't enough I'll convert the large foam undersuit pieces to vinyl.

Still have to do boots and lights and a neck seal and... jeez this list is too long. Time to get back to work!

quick question what did you use for the rubber peaces on the jaw of the helm i was brain storming some ideas but yours look flawless

I used a "pool connector" hose for the rebreathers. I think it's supposed to connect the pump or something, but basically I walked around Home Depot and bought the best thing I could find. Painted it up with 4-5 layers of flat black and done!

Here's the item I got:

http://www.homedepot.com/p/Pool-Shop-4-ft-Connector-Hose-69400/202524754#.UiQS_TbrxAs

--

Update time! Didn't make it for Dragon*Con but I should have more than enough time to finish by "Halo"ween. The undersuit came out looking pretty well, though I'm still debating whether or not I need to subtract more material from the torso. I'll get a pic of everything together once it's all dry, but for now I do have the updated vinyl part.

Not sure why the lighting is so bad, but it gets the point across. I did decide to go ahead and rip the foam off and use all vinyl, which was the right thing to do. It's much more flexible and less bulky than even the thin foam. Unfortunately I'm finding that the glue is already peeling off of the smooth side of the vinyl after about 48 hours, which means I need to find SOME way to sew this all together. I don't think I can do it by hand... I have the patience but the un-evenness in the stitches would drive me insane, provided I could even get the needle through all those layers. Once I can either figure out the sewing or find someone locally who can do it, I'll call that portion of the undersuit complete. Since I have additional time all of the sudden, I may fabricate something for the more exposed parts of the suit, like the shoulders/elbows/knees to hide the bare UA suit.

I also managed to find and use a pattern for the BlueRealm neck seal (despite their site being down for maintenance... thank you Google caching!), which turned out great... until it too started to peel apart. le sigh.

Still, all the pieces are there and it fits great. The last two pieces in the back overlap, and the velcro is completely hidden. Come to think of it, if I'm getting it sewn I may have a zipper installed for ease of use...

The boots also got some attention, as they were the main part of what kept me from the con. No matter what I did, I just could not get the three parts to line up correctly. I concluded that I really should have built the two-piece boots and just cut them apart at the end, but since I don't really want to redo them entirely I'm trying something different. I used a couple of small foam pieces on my helmet to close up some gaps, as it was much easier than glassing in such a small section. I figured, why not try the same thing on the boots.

Here's the original piece, on the better fitting of the two sides.

It. Would. Not. Line. Up. I know it's because I was rushing these to get them done for the con, but even so... who wants to start all over again! So I did this...

... which eventually turned into this.

I haven't worked out exactly how to do the recessed holes yet, but once I do I think this will be a good solution. Not perfect, but certainly much more workable than the previous piece. The foam on the sides is 5mm, though I'll be adding a second layer on the inside that overlaps inside of the boot as well, keeping it in place while moving. It should add enough strength, while also giving the entire "buckle" piece some stability. I don't think I'd ever do a foam build, but I'm coming to appreciate it in situations like this and on the helmet, where it just makes sense to not go all the way back through resin/sanding/bondo again.

With my time off tomorrow I may try some sewing again and see how it goes, though I don't hold out much hope. If it doesn't work still... well, there's always super glue!

I'm hoping to make it to "Halo"ween, as well! Hey, the glue solution is one to be appreciated. Flexibility is soooo useful in these kind of hobbies... I made a spine, fully intending to sew the thing directly to my undersuit...ended up hot gluing the vinyl and didn't sew a single stitch after the first piece.

Hot glue will separate over time. It's not so much a question of "if" as it is "when". I learned this on my first pair of scratch-built Gene Simmons dragon boots from Kiss. When I rebuilt them, I stitched all the seams with an upholstery sewing machine and they have yet to come apart, plus the added bonus of looking professionally-made. There really isn't any reliable alternative to stitching when it comes to clothing and vinyl. (Even vinyl adhesives start separating at the edges due to all the flexing from body movement.)

BlueMatter

New Member

Everything looks awesome. Great job, I really enjoyed looking through each page

Badledgend

New Member

How did you manage to size the handplates? I tried to size mine to 76mm (3 in) and the pieces got way too big

firefighter72

New Member

ur stuff looks great i love the plain black it just has a sense of greatness 2 it lol

I'm hoping to make it to "Halo"ween, as well! Hey, the glue solution is one to be appreciated. Flexibility is soooo useful in these kind of hobbies... I made a spine, fully intending to sew the thing directly to my undersuit...ended up hot gluing the vinyl and didn't sew a single stitch after the first piece.

Glue is great when it holds! I used it in a couple ways on the undersuit. First (and most successfully) was creating the edges on the vinyl; I would cut a section out using a pattern and leaving a good half inch around all edges, then notch out the corners and fold down the excess with a small glue bead along the crease. This gave me the exact shape of the pattern and nice crisp edges that had some relief. It holds nicely on the felt side, but where it's against the smooth vinyl is where I'm running into problems.

Hot glue will separate over time. It's not so much a question of "if" as it is "when". I learned this on my first pair of scratch-built Gene Simmons dragon boots from Kiss. When I rebuilt them, I stitched all the seams with an upholstery sewing machine and they have yet to come apart, plus the added bonus of looking professionally-made. There really isn't any reliable alternative to stitching when it comes to clothing and vinyl. (Even vinyl adhesives start separating at the edges due to all the flexing from body movement.)

Yeah, after finishing it I wasn't as happy with it as I'd hoped, but it'll work for Halloween. Still want to do the sewing version but alas, my machine doesn't handle the heavy vinyl workload that well. Still, I'll figure something out for the long haul.

Pretty much exactly what I experienced.. sewing machine bogs down trying to go through the layers. If I had any experience with it I might be able to figure out the right settings, but that's just not the case. I may have to look into finding someone that has a heavy-duty machine like you mentioned.

Everything looks awesome. Great job, I really enjoyed looking through each page

Thanks BlueMatter, it's been quite a journey! It's fun for me to read back sometimes too or look at old pictures and see how far it's come.

Excellent craftsmanship. I see this headed for Elite status. Keep up the attention to detail.

Thank you Fred, I really appreciate that. I see far too much wrong with it to ever be in Elite, but I think most people feel that way about their suits. We're all our own worst critics.

How did you manage to size the handplates? I tried to size mine to 76mm (3 in) and the pieces got way too big

Hey Bad, I measured from the front of my knuckles to the wrist joint. The tip of the handplate comes just over the proximal end of my fingers, and the rear of the plate is far enough out on my hand that I can have full wrist movement (unlike every other body part in this suit!).

ur stuff looks great i love the plain black it just has a sense of greatness 2 it lol

Thanks Fire! I had originally planned to add something like the spinal plates from Reach armor, but after trying it on I decided that it wouldn't look right, and the straps give enough to look at on the back without being cluttered.

--

Quick no-pic update! With the deadline now extended another 8 weeks, I have plenty of time to go back and touch up the parts I was rushing and didn't end up being happy with. Mostly, that's the boots. Every time I look at the bondo work along the edges on them I cringe. I'll be sanding the paint down and touching that up again, as well as possibly messing around with the torso attachment mechanism. It works, but the bolts tend to bind by the time I undo the bottom alignment posts and it turns into a major hassle. The bolts will probably stay, but I need to do something different with the piece underneath. Time will tell...

I went ahead and cut out the inner-most ridge of the torso rear section and it's more roomy now, so it's time to go back and try it with the undersuit again. If it fits better, I'll go onto adding in the back "fins" and their base, material TBD. Hope to have more pics up soon. Until then, thanks everyone for the comments! They're very much appreciated and help keep me going, almost ten months into this whole process now.

Glue is great when it holds! I used it in a couple ways on the undersuit. First (and most successfully) was creating the edges on the vinyl; I would cut a section out using a pattern and leaving a good half inch around all edges, then notch out the corners and fold down the excess with a small glue bead along the crease. This gave me the exact shape of the pattern and nice crisp edges that had some relief. It holds nicely on the felt side, but where it's against the smooth vinyl is where I'm running into problems.

Pretty much exactly what I experienced.. sewing machine bogs down trying to go through the layers. If I had any experience with it I might be able to figure out the right settings, but that's just not the case. I may have to look into finding someone that has a heavy-duty machine like you mentioned.

You'll find the canvas side of vinyl separating over time as well, especially with hot glue. Believe it or not, just your own body heat is enough to turn the glue "gummy". I've yet to find anything that will adhere decently to the plastic side due to the inherent oils in the vinyl. Even roughing up the surface to provide more grip (a tedious process, by the way) doesn't guarantee a reliable bond. A regular sewing machine is not designed for stitching vinyl. You might get away with it sewing just two layers (no folded edges over a backing piece - I'm talking strictly two layers), but you'll need a heavy duty needle (like what's used on coats), upholstery (or coat) thread, and the proper tension settings. Even then you'll probably need to hand walk the needle through. An upholstery machine makes it easy. Mine will do up to about 4 or 5 layers thick (great for overlapping hemmed seams), but at the higher end I too need to hand walk pieces through the machine.

You'll find the canvas side of vinyl separating over time as well, especially with hot glue. Believe it or not, just your own body heat is enough to turn the glue "gummy". I've yet to find anything that will adhere decently to the plastic side due to the inherent oils in the vinyl. Even roughing up the surface to provide more grip (a tedious process, by the way) doesn't guarantee a reliable bond. A regular sewing machine is not designed for stitching vinyl. You might get away with it sewing just two layers (no folded edges over a backing piece - I'm talking strictly two layers), but you'll need a heavy duty needle (like what's used on coats), upholstery (or coat) thread, and the proper tension settings. Even then you'll probably need to hand walk the needle through. An upholstery machine makes it easy. Mine will do up to about 4 or 5 layers thick (great for overlapping hemmed seams), but at the higher end I too need to hand walk pieces through the machine.

I was playing around with some tension settings on the machine the other night and was able to get it to breeze through 3 layers of vinyl without issue, but when I moved into the pieces I'd already created I ran into problems. I suspect it's bogging down going through the hot glue that I wasn't able to remove, so I'll either have to pull them apart and do a more thorough removal of the glue or re-cut the top layer pieces. Either way, the machine will work, which is good news!

--

Currently waiting on materials to arrive from Amazon to continue with this build. Ordered some more powerful neodymium magnets for the torso and cod, since I'm tired of them pulling apart when even minor pressure is applied. Also got some smaller center-release buckles to attach my foam boot pieces, and a balaclava to keep my head dry underneath the neck seal and helmet.

I did burn out a little in the week before Dragon*Con, so I've been dabbling with other stuff in the weeks since. I'll still have the build done by Halloween, but I don't want to work on it because I feel like I have to or am obligated to do so. The last thing I want is for it to become another job, so I've been taking it at a slower pace and am still making progress. I should be back with another update fairly soon, provided everything arrives on time. Maybe even some pictures this time!

Awesome build Halex. I like your approach to the undersuit parts. Looking forward to seeing this come together!

As for the magnets, would you ever use them to keep armor in place? I'm using webbing/clips to hold major parts together, but then securing with strong velcro - but your post made me consider having mounted magnets in my undersuit and on an armor piece in key places to secure. Like holding up gauntlets or bicep plates in place. Think they would be more secure than velcro?

As for the magnets, would you ever use them to keep armor in place? I'm using webbing/clips to hold major parts together, but then securing with strong velcro - but your post made me consider having mounted magnets in my undersuit and on an armor piece in key places to secure. Like holding up gauntlets or bicep plates in place. Think they would be more secure than velcro?

Your build is amazing! Very inspiring!

I suspect it's bogging down going through the hot glue that I wasn't able to remove, so I'll either have to pull them apart and do a more thorough removal of the glue or re-cut the top layer pieces. Either way, the machine will work, which is good news!

True, the existing hot glue is too rubbery and thick for the scrawny sewing machine motor to push a needle through. Even if you do get it to work, the needle will gum up with glue. How do I know this? Been there, done that.

- Status

- Not open for further replies.