macktruck

Member

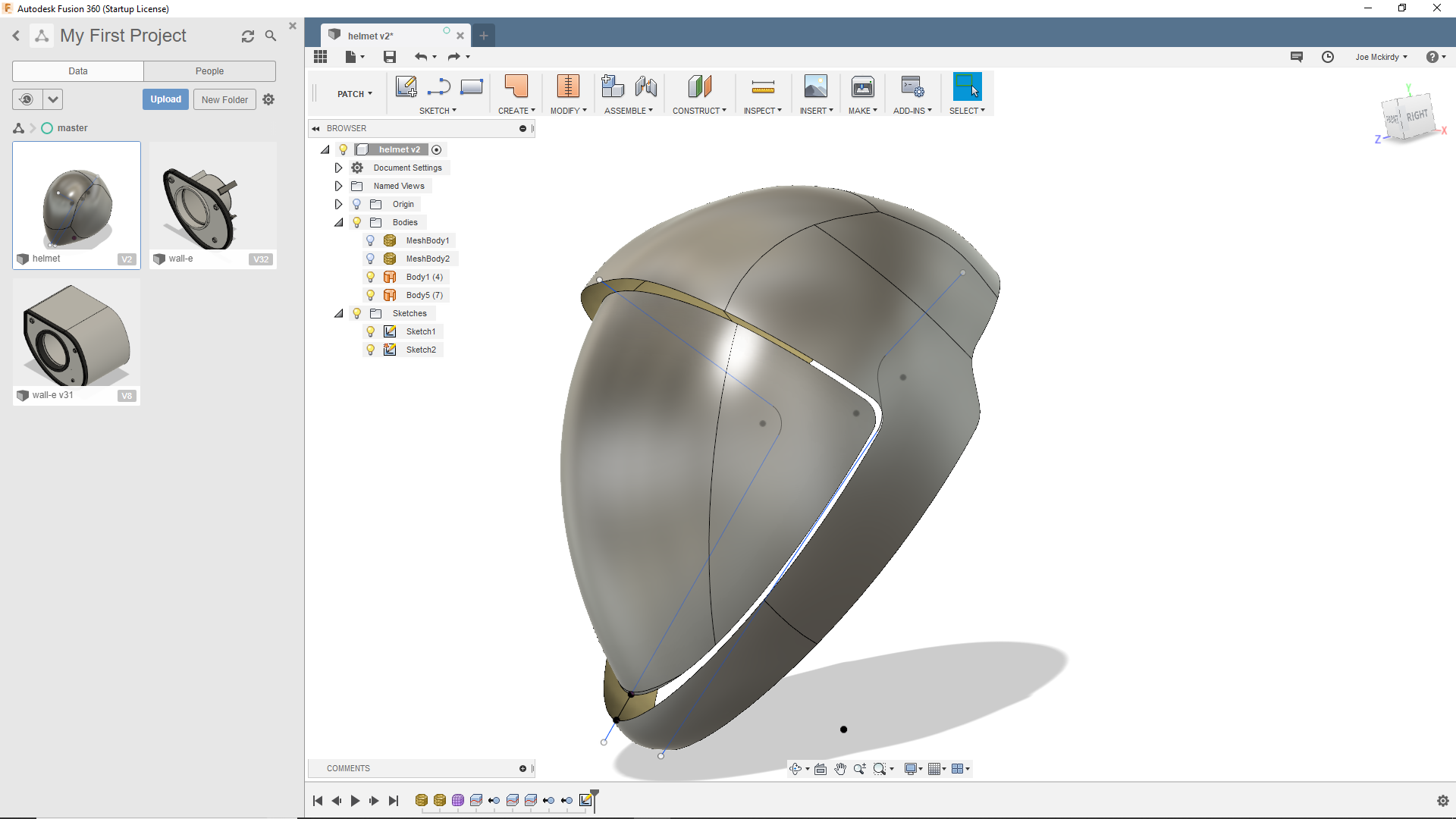

I was recently doing work on this forum and several people suggested I use Fusion 360 for desighning. I've started another project and tried to use Fusion 360 But I can't find a solution to my current problem.

I have made one "form" with several bodies from it. I have used a sketch to trip the objects but I can not find any way to join the two objects.

I've tried sweep, trim, and bridge.

Sweep doesn't let me select the line on a new sketch, trim doesn't find my selections to be valid, and bridge doesn't work either.

How should I go about fixing this?

I have made one "form" with several bodies from it. I have used a sketch to trip the objects but I can not find any way to join the two objects.

I've tried sweep, trim, and bridge.

Sweep doesn't let me select the line on a new sketch, trim doesn't find my selections to be valid, and bridge doesn't work either.

How should I go about fixing this?

Last edited: