glasscutter

Jr Member

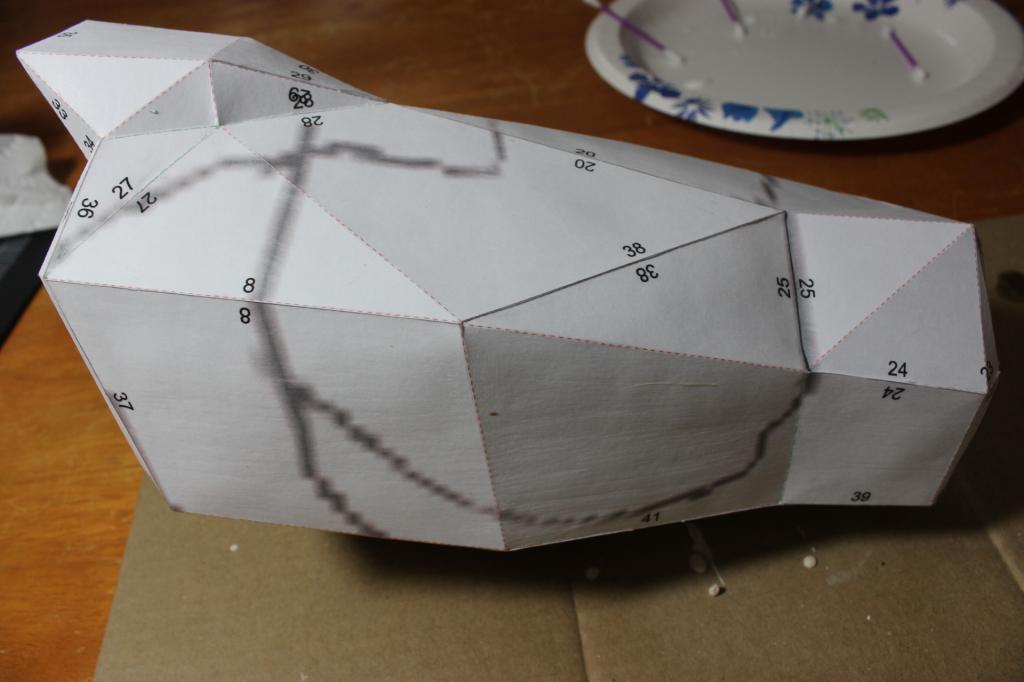

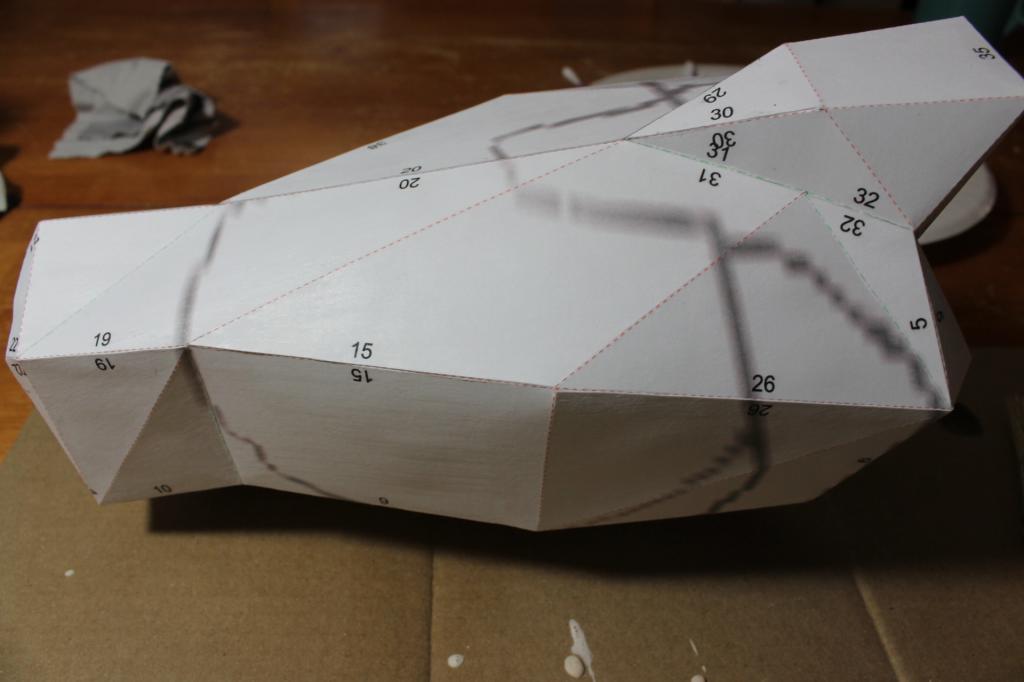

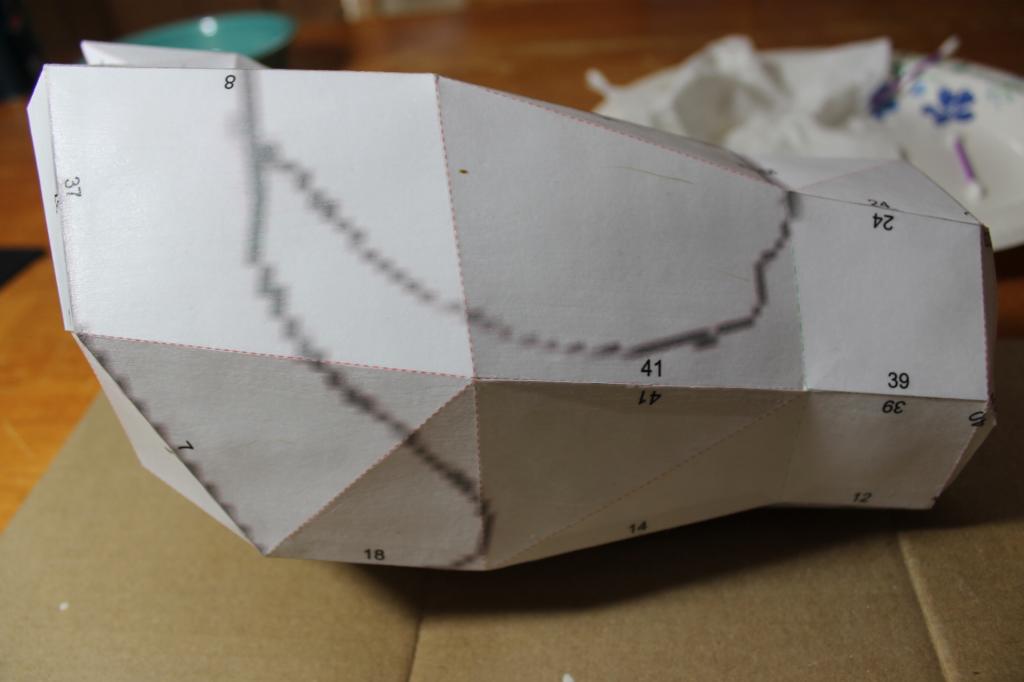

This update is going back to the sealing stage for a new test. After seeing some of the warping my wife suggested using Mod Podge to seal the cardstock instead of Acrylic spray sealer. She uses it in scrapbook/jewelry making. So I figured what the heck, it couldn’t hurt. I used a LD version of the Mark V CE forearm for the test victim. Nice big pieces of cardstock just begging to warp lol. Hoping it works out because it is non-toxic, washes off with soap and water, and doesn’t ruin brushes.

The first few coats were very light almost like dry brushing.

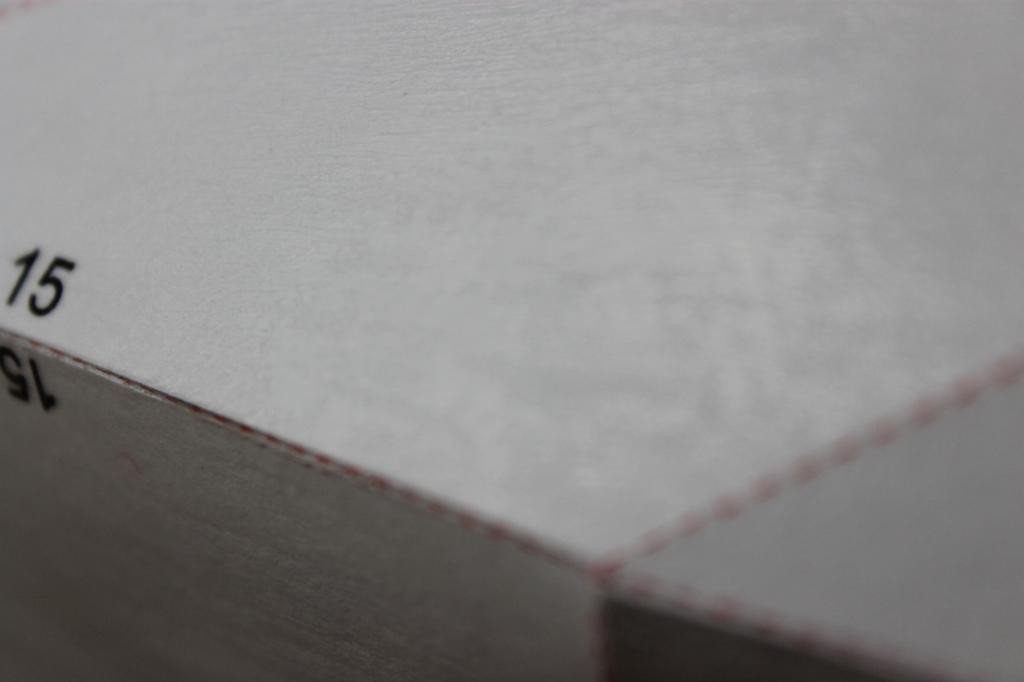

After the first coat the only warping was from me handling it while coating. Oh and my daughter poking at it and declaring, “My imperial helmet is harder and better”, and then walking off. I love the way little kids think lol. Anyway, the first two coats were very light and mostly covered the piece. The below close ups are after the first light coat.

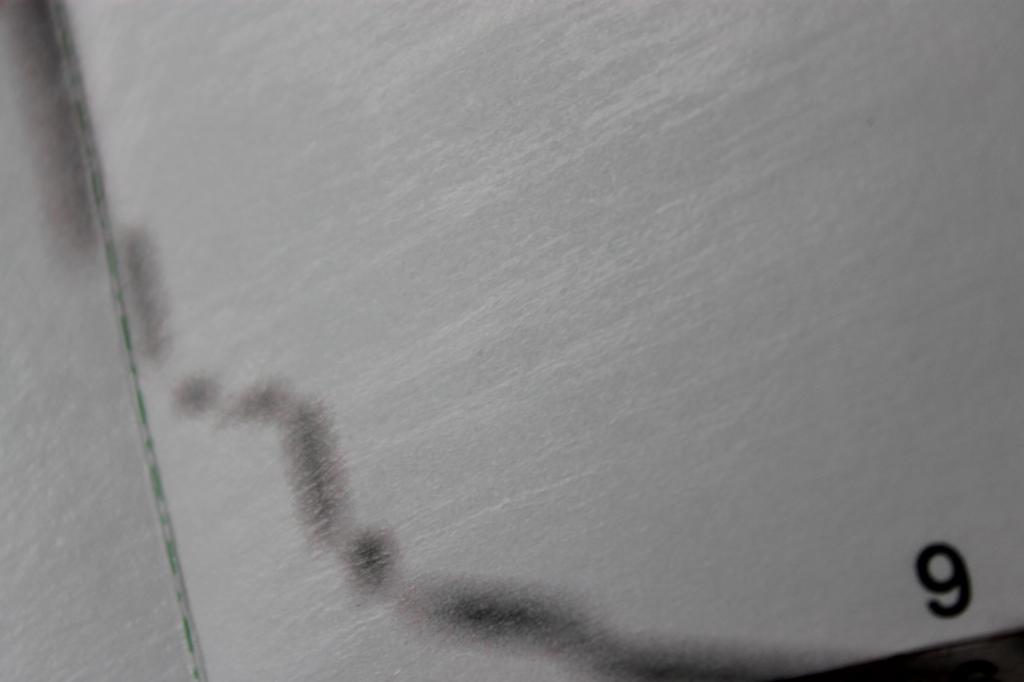

And then the second light coat.

After that a full light coat was put on the entire piece.

No real warping to speak of yet. Another full coat has been applied on the outside and 1 really light and 1 full coat on the inside. Pics of that with some outside resin later this week.

The first few coats were very light almost like dry brushing.

After the first coat the only warping was from me handling it while coating. Oh and my daughter poking at it and declaring, “My imperial helmet is harder and better”, and then walking off. I love the way little kids think lol. Anyway, the first two coats were very light and mostly covered the piece. The below close ups are after the first light coat.

And then the second light coat.

After that a full light coat was put on the entire piece.

No real warping to speak of yet. Another full coat has been applied on the outside and 1 really light and 1 full coat on the inside. Pics of that with some outside resin later this week.

Attachments

-

IMG_0640_zpsf921dec1.jpg58 KB · Views: 161

IMG_0640_zpsf921dec1.jpg58 KB · Views: 161 -

IMG_0632_zps598d2910.jpg51.7 KB · Views: 156

IMG_0632_zps598d2910.jpg51.7 KB · Views: 156 -

IMG_0639_zpsd4ac32fa.jpg43.3 KB · Views: 163

IMG_0639_zpsd4ac32fa.jpg43.3 KB · Views: 163 -

IMG_0638_zps4563b8b6.jpg39.9 KB · Views: 162

IMG_0638_zps4563b8b6.jpg39.9 KB · Views: 162 -

IMG_0635_zpsf6bf726e.jpg36.7 KB · Views: 177

IMG_0635_zpsf6bf726e.jpg36.7 KB · Views: 177 -

IMG_0634_zps183580ab.jpg28.1 KB · Views: 151

IMG_0634_zps183580ab.jpg28.1 KB · Views: 151 -

IMG_0633_zpsa73cd57f.jpg45.2 KB · Views: 164

IMG_0633_zpsa73cd57f.jpg45.2 KB · Views: 164