Very nice job with your pep work, looks good with no warping. As for the support pieces, you will need them. They are used to help prevent warping in pieces with out a lot of structure to them (like the bicep). What you want to do is test fit it, make sure it fits all proper and then put the support struts in before you start to resin it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Largo's MK VI Build WIP

- Thread starter Largo Usagi

- Start date

- Status

- Not open for further replies.

Largo Usagi

Jr Member

Sweet thanks a lot.

Just picked up some gloves to attach the hand pieces to

They where $25 at dunhams sports well worth it. Just got to get a seam ripper and pull off the under armor logo and they will be good to go.

If any one is interested in them here is a link

http://www.dunhamssports.com/products/under-armour-adult-clean-up-batting-gloves/

Hopefully tonight I will finish cutting out the shoulder pieces and at least get 1 of the assembled.

Just picked up some gloves to attach the hand pieces to

They where $25 at dunhams sports well worth it. Just got to get a seam ripper and pull off the under armor logo and they will be good to go.

If any one is interested in them here is a link

http://www.dunhamssports.com/products/under-armour-adult-clean-up-batting-gloves/

Hopefully tonight I will finish cutting out the shoulder pieces and at least get 1 of the assembled.

Cereal Killl3r

Well-Known Member

Your pep work looks really neat and clean!

Largo Usagi

Jr Member

Thanks for all the positive remarks about my peping work. I live in michigan and it will be a long while before I have warm weather and when it comes it will be high humidity most of the time. For fiber glassing I read that the temp should be about 75+ could I do it in the mid and upper 60's or will that ruin my peps?

This is what my weather is looking like for the next few days

http://www.weather.com/weather/tenday/Canton+MI+48187

And the biggest reason I have slowed up on this is because I want to see how these pieces handle the resin fiberglass and bondo so i know what each step can do for detail and what errors I cant cover up.

Thanks again for all the feedback

-Largo

This is what my weather is looking like for the next few days

http://www.weather.com/weather/tenday/Canton+MI+48187

And the biggest reason I have slowed up on this is because I want to see how these pieces handle the resin fiberglass and bondo so i know what each step can do for detail and what errors I cant cover up.

Thanks again for all the feedback

-Largo

7th Brig Walker

Jr Member

As for the weather im not sure, but I think it just slows down the curing process on the resin.

Anyway, Great work and Im looking forward to see what you Sir will make.

Anyway, Great work and Im looking forward to see what you Sir will make.

Largo Usagi

Jr Member

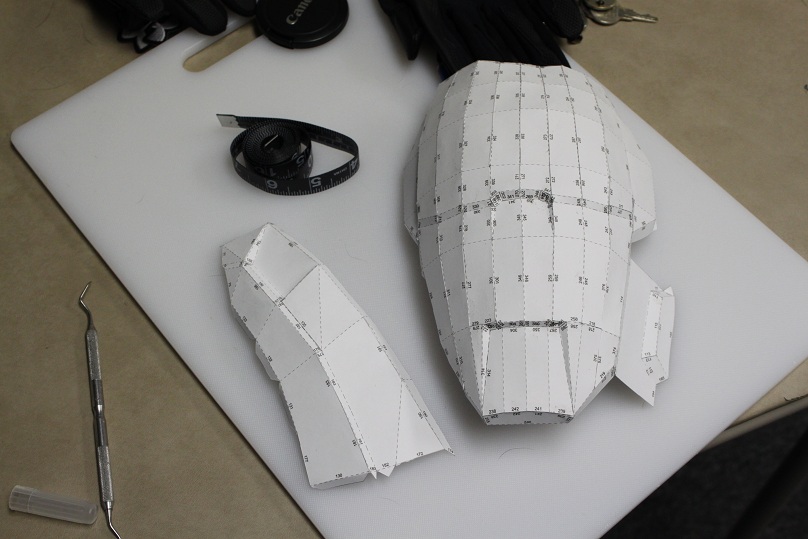

Here is today's progress, I am making a shoulder piece, not sure what one, I printed out both sides at the same time.

I Removed the under armor symbol from the gloves and started assembling one of the shoulders.

I Removed the under armor symbol from the gloves and started assembling one of the shoulders.

Largo Usagi

Jr Member

Here is the left shoulder fully assembled without the supports, I cant tell if this is to big it seems massive but compared to the other parts it seems to scale OK.

and that is resting on a dogs toy, need to get a manikin or something for this stuff.

The pep itself needs a little bit of work outside of the rigidity but all in all it turned out nice. I got about a 3rd of the right arm cut out and that will be assembled soon as well.

As a reference the part seems to be sized OK for length up and down my arms but the diameter seems a bit to much

Thanks for all the feedback

and that is resting on a dogs toy, need to get a manikin or something for this stuff.

The pep itself needs a little bit of work outside of the rigidity but all in all it turned out nice. I got about a 3rd of the right arm cut out and that will be assembled soon as well.

As a reference the part seems to be sized OK for length up and down my arms but the diameter seems a bit to much

Thanks for all the feedback

Largo Usagi

Jr Member

Well today I resin coated the majority of the parts I had made already, found out that even at low temps that **** cures FAST. After a few hours it was rock hard, they need a bit of touch up work but for a first time use I was very happy with the results.

On top of resin coating the peps I had done from before I also cut out every part for my right shoulder and will start building that on Sunday, I need to find a spartan template to show overall progress.

At 56.4f outside I was able to resin properly all of my peps with 3M bondo fiberglass resin. After researching the lowest temperature that fiberglass resin can be used is about 55 so I was splitting hairs today, I had a heat gun just in case though.

The workspace

And the finished product all parts not shown

So if any one else is wondering if they can do resin work in cool weather, I am confirming it is possible, and the resin will cure faster than you expect, even on the coldest side of the scale.

On top of resin coating the peps I had done from before I also cut out every part for my right shoulder and will start building that on Sunday, I need to find a spartan template to show overall progress.

At 56.4f outside I was able to resin properly all of my peps with 3M bondo fiberglass resin. After researching the lowest temperature that fiberglass resin can be used is about 55 so I was splitting hairs today, I had a heat gun just in case though.

The workspace

And the finished product all parts not shown

So if any one else is wondering if they can do resin work in cool weather, I am confirming it is possible, and the resin will cure faster than you expect, even on the coldest side of the scale.

Looks great on the resin. I'm from MI. Too, Sorry I didn't take the time to tell you that you can resin all year with the Hot box method. Well most of the year any way I find that you need it to at least be warm enuff to work with only latex gloves on 40 works great. A Hot box is simply that A box large enuff to put you're part in and a 100wt light bulb. As for scale you have to ask what type of under suit do I want, and add that to you measurements. That said, All you're hard work is really starting to show:cool

Largo Usagi

Jr Member

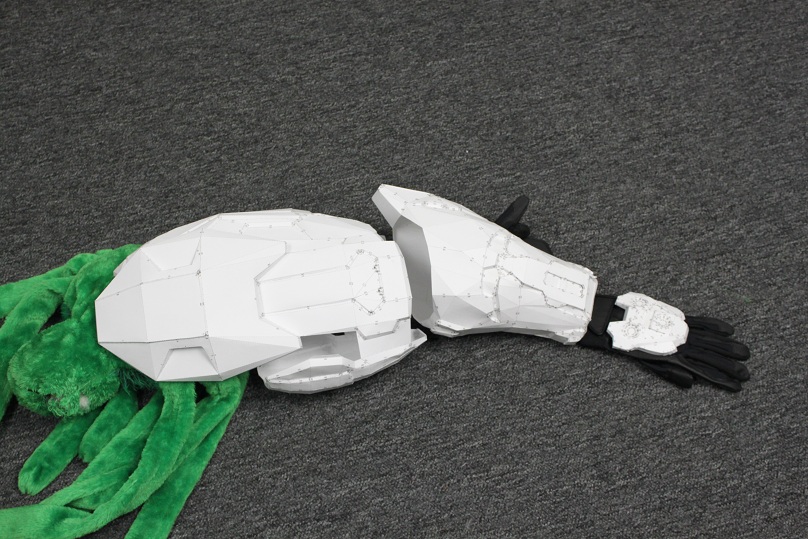

I finished up the other shoulder and that concludes the arms.

This is to show the scaling

And those are the completed pieces thus far

In the middle of the arms I have an arduino that will be used to control lights and other electronic things, I plan on hooking that into a raspberry pi and really go to town with the electronics on this armor.

This is to show the scaling

And those are the completed pieces thus far

In the middle of the arms I have an arduino that will be used to control lights and other electronic things, I plan on hooking that into a raspberry pi and really go to town with the electronics on this armor.

Largo Usagi

Jr Member

So i started working on the legs, starting with the feet, I am trying to figure out if i should use combat boots as the shoes or regular tennis shoes. both are about the same size so they will fit just fine but in terms of appearance what ones will look better.

Thanks for the input and I will get some more pictures up soon.

EDIT

Here is the current boot so far,

Thanks for the input and I will get some more pictures up soon.

EDIT

Here is the current boot so far,

Largo Usagi

Jr Member

So today I did my first bit of fiber glassing. It was great, I am truly shocked at how durable one layer of mat is. Granted it started to get rather messy, is there a recommended type of glove to use because the rubber ones I have seem to attract the fiberglass.

I will get some pics up soon, also is bondo sold in less than a gallon

EDIT

here is a photo, this is the first time I have had the for arm part on myself since I finished peping it.

Getting there this week, the boots get done.

this week, the boots get done.

I will get some pics up soon, also is bondo sold in less than a gallon

EDIT

here is a photo, this is the first time I have had the for arm part on myself since I finished peping it.

Getting there

Largo Usagi

Jr Member

I got my first boot made up, working on the second, this is how it scales to my combat boots.

I am wondering if the combat boots will interfere with the shin pieces at all, or if there is some thing special that needs to be taken into account if i use these boots with the armor. I have an alternative shoe I can use that would be fully contained inside of the final piece so that is an option too. Any feedback or recommendations here would be great.

Thanks for the feedback as always and I hope to have the legs finished in the next 2 weeks.

I am wondering if the combat boots will interfere with the shin pieces at all, or if there is some thing special that needs to be taken into account if i use these boots with the armor. I have an alternative shoe I can use that would be fully contained inside of the final piece so that is an option too. Any feedback or recommendations here would be great.

Thanks for the feedback as always and I hope to have the legs finished in the next 2 weeks.

Largo Usagi

Jr Member

Well its been a while since I updated, but thats mostly because I have been doing fiber glass work and that really doesn't change the appearance of the parts. This week I have been doing something else Here is a picture

If the weather holds I will resin and fiberglass it this weekend and then start bond work, I ended up with a gallon of that so I got plenty.

-Largo

If the weather holds I will resin and fiberglass it this weekend and then start bond work, I ended up with a gallon of that so I got plenty.

-Largo

Largo Usagi

Jr Member

Helmet looks great.

Thanks, due to our great states terrible weather patterns, I won't be able to resin coat and fiberglass this until next week Tuesday or Thursday; And that is stating that the weather people got it right and for michigan... yah right.

Largo Usagi

Jr Member

I got a bit of work done on my helmet, so here is some updates on that.

Currently Looks like this

I found that 1 Layer of cloth around the whole helmet would sufficiently harden the piece. Then around the openings (neck and the lens area) I added a layer of mat. This gave the durability that I wanted and kept the part from flexing almost completely. There is a spot on the top that I will reinforce with some mat tomorrow but for the most part it was fine.

You can see the cloth here

And here is the effect of the mat, you can see how thick the fiberglass is around the edge and it helps a lot.

I have a little warp in the pep here and it was made permanent in the fiber glassing stage but I figure I can sand it flat.

How I will be padding the helmet

And most importantly how it fits for scale

For the raised surfaces I am trying to decide what to do, and I am looking for high quality and cheap. My best though right now is to get some 1/16th or 1/32 inch balsa wood and glue my template onto the sheet with a spray adhesive, then gluing it down and painting on some resin to harden it because its a very soft wood.

If any one else has some input on a way to give nice clean raised surfaces I am all ears.

-Largo

Currently Looks like this

I found that 1 Layer of cloth around the whole helmet would sufficiently harden the piece. Then around the openings (neck and the lens area) I added a layer of mat. This gave the durability that I wanted and kept the part from flexing almost completely. There is a spot on the top that I will reinforce with some mat tomorrow but for the most part it was fine.

You can see the cloth here

And here is the effect of the mat, you can see how thick the fiberglass is around the edge and it helps a lot.

I have a little warp in the pep here and it was made permanent in the fiber glassing stage but I figure I can sand it flat.

How I will be padding the helmet

And most importantly how it fits for scale

For the raised surfaces I am trying to decide what to do, and I am looking for high quality and cheap. My best though right now is to get some 1/16th or 1/32 inch balsa wood and glue my template onto the sheet with a spray adhesive, then gluing it down and painting on some resin to harden it because its a very soft wood.

If any one else has some input on a way to give nice clean raised surfaces I am all ears.

-Largo

Largo Usagi

Jr Member

Well I have a target date to finish by, November 1st. That will get it done for Yumicon as well as the Halo 4 launch.

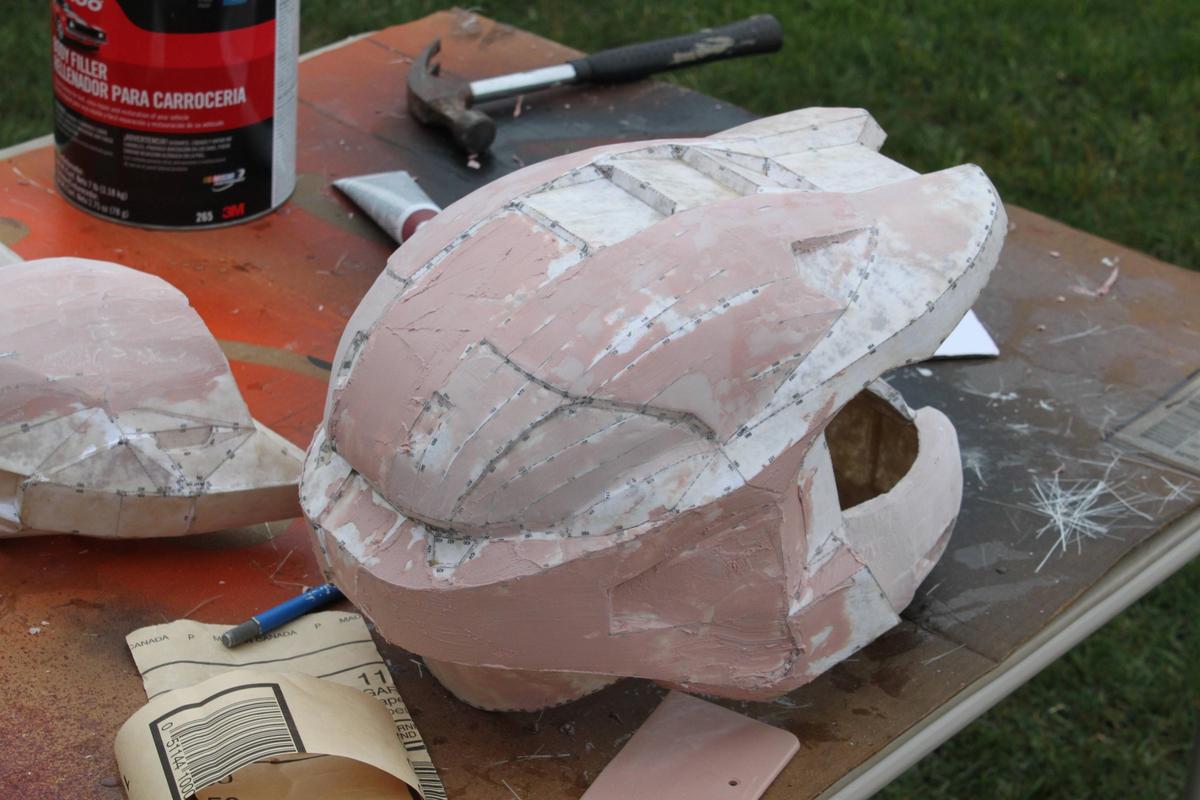

Any ways today I got my first experience with some bondo. I started coating my helmet section by section. I found that about 5 minutes after it got to hard to work it was amazingly easy to work an exacto knife through. That enabled me to get some very nice sharp corners.

I almost finished smoothing out my helmet today but Michigan weather got the best of my time and I didn't get to finish.

Here are some pictures that I took

First application of bondo

A bit of work done on the helmet

More Helmet work

And where I am at after a few hours of work

I also got my chest piece printed out, 30 pages of work to do there, bondo and resin by day, pep by night. I plan on getting this done ASAP

Any ways today I got my first experience with some bondo. I started coating my helmet section by section. I found that about 5 minutes after it got to hard to work it was amazingly easy to work an exacto knife through. That enabled me to get some very nice sharp corners.

I almost finished smoothing out my helmet today but Michigan weather got the best of my time and I didn't get to finish.

Here are some pictures that I took

First application of bondo

A bit of work done on the helmet

More Helmet work

And where I am at after a few hours of work

I also got my chest piece printed out, 30 pages of work to do there, bondo and resin by day, pep by night. I plan on getting this done ASAP

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 2,410