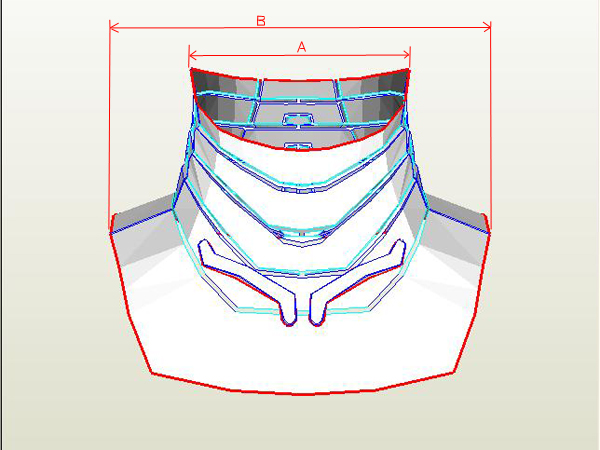

Ironman neck scaling guide

First get your neck on screen like the image above. Zoom till "B" is 100mm across on screen then measure "A" (about 56mm, my office light wasn't on and I have lots of junk in the way of the light switch). You now know your neck opening is 56% of the total width "B". We will call the percentage "C". So the equation is A/C X 100=B. So measure your RL neck width, mine is 140mm including the thickness of my foam. 140/56X100=250. So the total width of my neck piece is 250mm.

Hope this should sort out your problem

Tom.

Edit: You may want to add a little to YOUR neck width so you have a bit of space in there or you might find it a little tight. I think I added 10mm so there is a 5mm gap all the way around.

Drack - you rock man! Thanks for all that effort dude. I'm just tweaking the helmet now with padding, lighting and faceplate mechanism then I will be onto the neck next.

Cheers bloke!