Hello everyone at the 405th! After a bit of thinking and good criticism I am back with a very detailed tutorial that will guide you step by step in how to use Fiberglass Spackling Paste, if you dont have a clue what Bondo is in Europe.

What is Bondo? Bondo Bodyfiller is a two-part putty which is a Polyester Resin product, when mixed with harderner becomes very hard. The name Bondo is commonly used in the U.S as a genericized trademark to refer to all auto-repair putties or so-called plastic body fillers.

This tutorial will help you through how to use Fiberglass Spackling Paste instead, if you are having a hard time finding Bondo, or just wanna use something that will get ROCK-hard after it has dried.

If anyone from the U.S is interested in this method, use Bondo Glass as Fiberglass Spackling Paste, or take normal Bondo and very small and cut stripes of fiberglass cloth.

We will start with what we need make a Rock-hard helmet:

-----------------------------------------------------------------------------------

1x Respirator (SAFETY FIRST, THIS STUFF IS TOXIC)

3x Pairs of Latex, vinyl, or nitrile gloves (I think you will need a couple if you get any of the paste on your hands)

1x Eye protector (Dont get unneccesary dust in your eyes when you sand, your eyes dont have a price!)

1x Container with Fiberglass Spackling Paste with a hardener included! (Ask in your shop if its included!)

1x Container of Easy-to-sand Spackling Paste with a hardener included (Ask in your shop if its included!)

1x SpacklingTool to apply the Putty on the helmet

1-2x Brushes

1-3x Containers for both the Resin and the Putty

1-3x Things to mix with (Like my wood stick on the picture)

1x Fiberglass Resin (And make sure it comes with a harderner, or ask in shop for the right one and buy it seperate)

1x Primer

1x Rotary tool

1x Dremel

1-4x Sand Papers to the Rotary Tools

1x Piece of armor that has been Resined and Fiberglassed on the inside first before starting this!

--------------------------------------------------------------------------------------

Step One

Pick up your helmet and choose what spots to smoothen. Sand away all the edges by using a rotary tool, by doing this you will sand through the orginal paper and down to the fiberglass cloth. This is why it is so important to fiberglass the inside first before sanding!

Step Two

Time to put your respirator ON and gloves!

Pick up your container and your Spacklingtool. Scoop out as much as you want, when I made my helmet I used 3/4 of the can on the picture up in the tutorial. But remember, you can always mix more later, but you cant put it back! Then it may vary on how much harderner to use, but you can always read on the back of Fiberglass Spacklingpaste can! At least on mine it says "Use 3 % of the harderner and mix with the fiberglass paste, so scoop out a chunk as big as a golfball and then add 3 centimeters of harderner". After you have added both of these things, mix untill you dont see the harderners colour in your paste any longer! Also, the curing time stands on the back of the Fiberglass Spacklingpaste can, on mine it stands 15 minutes. But I prefer to wait a night, so my sandpapers dont get destroyed because any uncured paste will stick on them.

Your decide how thick you want the paste cover to be, depending how much you're gonna smooth. But I recommend not to thick. Normal would be to cover the selected area untill you cant see the orginal paper, but let it still be a thin cover.

Step Three

Now its time to look/touch all around your helmet to look for "wet/sticky spots". You shouldnt have any if you mixed everything well, but we wanna make sure your sandpapers dont get wasted. If you find any, try to get the most off using soft paper.

If you didnt find any wet spots, you can start sanding with your rotary tool (dremel). If you do, cover the area where its wet with some Fiberglass Resin, then sand.

Step Four

After you sand it, your helmet will have these small little "Valleys" and look alittle like Grand Canyon. It wont be as smooth as you want. But you should have managed to get it into the shape you want by using a curving motion (if you want it too look like mine!). Now its time to add another coat of Fiberglass Resin. I think there are alot of good tutorials how to mix Fiberglass Resin, so I wont make any in this tutorial, but I will link one for example: http://405th.com/forums/index.php?showtopic=2287

After it has dried, your helmet surface will feel very smooth and nice to touch.

Step Five

Now, I would recommend that you sand again and then add another coat of resin, and re-do that untill you got a satisfying result; Meaning that it primarily has the final shape that you want it to have.

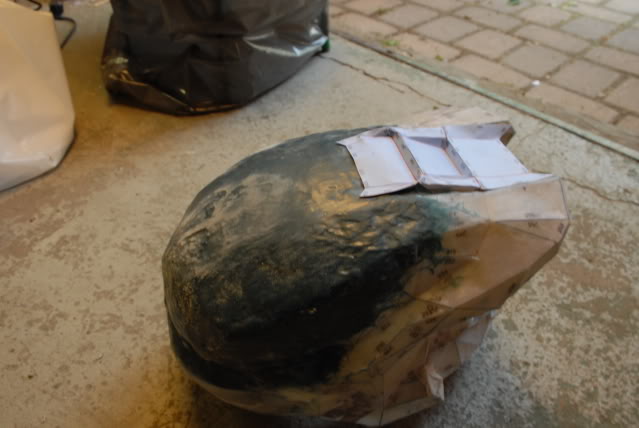

Step Six

When you're done with Step Five, it's time to do the last bit of smoothing to get it just as we want it to be. Take your Easy-to-Sand Spacklingpaste and mix with your harderner just like the Fiberglass paste. But as I mentioned before, READ ON THE BACK OF THE CAN for special instructions of your putty. Apply as you did with your fiberglass paste. Also check for the curing time on the back of your can.

(As you can see in the image, there's still some of the yellow harderner visible, meaning its not mixed well enough!)

Step Seven

After it has dried, sand with your rotary tools and make it smoooooth. If you want it on more areas, re-do Step Six and sand after it has dried.

Step Eight

Add a final coat of Fiberglass Resin, and then add your Primer, this makes it easier to see spots that haven't been properly smoothed yet. Wait untill the Primer has dried and then re-do (add some easy-to-sand Spackling Paste, sand and then add Fiberglass Resin).

Step Nine

When you're finally happy with your smoothing, you can start adding details. Sigma-LS has a great tutorial for this: http://405th.com/forums/index.php?showtopic=14625 .

I hope this will help people feel more confident when starting the smoothing, and its a lot clearer than my last tutorial: http://405th.com/forums/index.php?showtopic=18336

I think I was in too much of a rush, and wanted to make it to the "veterans" level too quick. It created more questions than answers I believe.

If you are unsure of ANYTHING, PM me!

And I think all mods and admins on this site are great, but I would really would like to thank Deadguy for being so encouraging for me to start making this tutorial! You're the Best Deadguy!

Please Comment and if you think anything should be made another way, write it in the comments!

All The Best and Good Luck With Your Project!

/Tahu

What is Bondo? Bondo Bodyfiller is a two-part putty which is a Polyester Resin product, when mixed with harderner becomes very hard. The name Bondo is commonly used in the U.S as a genericized trademark to refer to all auto-repair putties or so-called plastic body fillers.

This tutorial will help you through how to use Fiberglass Spackling Paste instead, if you are having a hard time finding Bondo, or just wanna use something that will get ROCK-hard after it has dried.

If anyone from the U.S is interested in this method, use Bondo Glass as Fiberglass Spackling Paste, or take normal Bondo and very small and cut stripes of fiberglass cloth.

We will start with what we need make a Rock-hard helmet:

-----------------------------------------------------------------------------------

1x Respirator (SAFETY FIRST, THIS STUFF IS TOXIC)

3x Pairs of Latex, vinyl, or nitrile gloves (I think you will need a couple if you get any of the paste on your hands)

1x Eye protector (Dont get unneccesary dust in your eyes when you sand, your eyes dont have a price!)

1x Container with Fiberglass Spackling Paste with a hardener included! (Ask in your shop if its included!)

1x Container of Easy-to-sand Spackling Paste with a hardener included (Ask in your shop if its included!)

1x SpacklingTool to apply the Putty on the helmet

1-2x Brushes

1-3x Containers for both the Resin and the Putty

1-3x Things to mix with (Like my wood stick on the picture)

1x Fiberglass Resin (And make sure it comes with a harderner, or ask in shop for the right one and buy it seperate)

1x Primer

1x Rotary tool

1x Dremel

1-4x Sand Papers to the Rotary Tools

1x Piece of armor that has been Resined and Fiberglassed on the inside first before starting this!

--------------------------------------------------------------------------------------

Step One

Pick up your helmet and choose what spots to smoothen. Sand away all the edges by using a rotary tool, by doing this you will sand through the orginal paper and down to the fiberglass cloth. This is why it is so important to fiberglass the inside first before sanding!

Step Two

Time to put your respirator ON and gloves!

Pick up your container and your Spacklingtool. Scoop out as much as you want, when I made my helmet I used 3/4 of the can on the picture up in the tutorial. But remember, you can always mix more later, but you cant put it back! Then it may vary on how much harderner to use, but you can always read on the back of Fiberglass Spacklingpaste can! At least on mine it says "Use 3 % of the harderner and mix with the fiberglass paste, so scoop out a chunk as big as a golfball and then add 3 centimeters of harderner". After you have added both of these things, mix untill you dont see the harderners colour in your paste any longer! Also, the curing time stands on the back of the Fiberglass Spacklingpaste can, on mine it stands 15 minutes. But I prefer to wait a night, so my sandpapers dont get destroyed because any uncured paste will stick on them.

Your decide how thick you want the paste cover to be, depending how much you're gonna smooth. But I recommend not to thick. Normal would be to cover the selected area untill you cant see the orginal paper, but let it still be a thin cover.

Step Three

Now its time to look/touch all around your helmet to look for "wet/sticky spots". You shouldnt have any if you mixed everything well, but we wanna make sure your sandpapers dont get wasted. If you find any, try to get the most off using soft paper.

If you didnt find any wet spots, you can start sanding with your rotary tool (dremel). If you do, cover the area where its wet with some Fiberglass Resin, then sand.

Step Four

After you sand it, your helmet will have these small little "Valleys" and look alittle like Grand Canyon. It wont be as smooth as you want. But you should have managed to get it into the shape you want by using a curving motion (if you want it too look like mine!). Now its time to add another coat of Fiberglass Resin. I think there are alot of good tutorials how to mix Fiberglass Resin, so I wont make any in this tutorial, but I will link one for example: http://405th.com/forums/index.php?showtopic=2287

After it has dried, your helmet surface will feel very smooth and nice to touch.

Step Five

Now, I would recommend that you sand again and then add another coat of resin, and re-do that untill you got a satisfying result; Meaning that it primarily has the final shape that you want it to have.

Step Six

When you're done with Step Five, it's time to do the last bit of smoothing to get it just as we want it to be. Take your Easy-to-Sand Spacklingpaste and mix with your harderner just like the Fiberglass paste. But as I mentioned before, READ ON THE BACK OF THE CAN for special instructions of your putty. Apply as you did with your fiberglass paste. Also check for the curing time on the back of your can.

(As you can see in the image, there's still some of the yellow harderner visible, meaning its not mixed well enough!)

Step Seven

After it has dried, sand with your rotary tools and make it smoooooth. If you want it on more areas, re-do Step Six and sand after it has dried.

Step Eight

Add a final coat of Fiberglass Resin, and then add your Primer, this makes it easier to see spots that haven't been properly smoothed yet. Wait untill the Primer has dried and then re-do (add some easy-to-sand Spackling Paste, sand and then add Fiberglass Resin).

Step Nine

When you're finally happy with your smoothing, you can start adding details. Sigma-LS has a great tutorial for this: http://405th.com/forums/index.php?showtopic=14625 .

I hope this will help people feel more confident when starting the smoothing, and its a lot clearer than my last tutorial: http://405th.com/forums/index.php?showtopic=18336

I think I was in too much of a rush, and wanted to make it to the "veterans" level too quick. It created more questions than answers I believe.

If you are unsure of ANYTHING, PM me!

And I think all mods and admins on this site are great, but I would really would like to thank Deadguy for being so encouraging for me to start making this tutorial! You're the Best Deadguy!

Please Comment and if you think anything should be made another way, write it in the comments!

All The Best and Good Luck With Your Project!

/Tahu