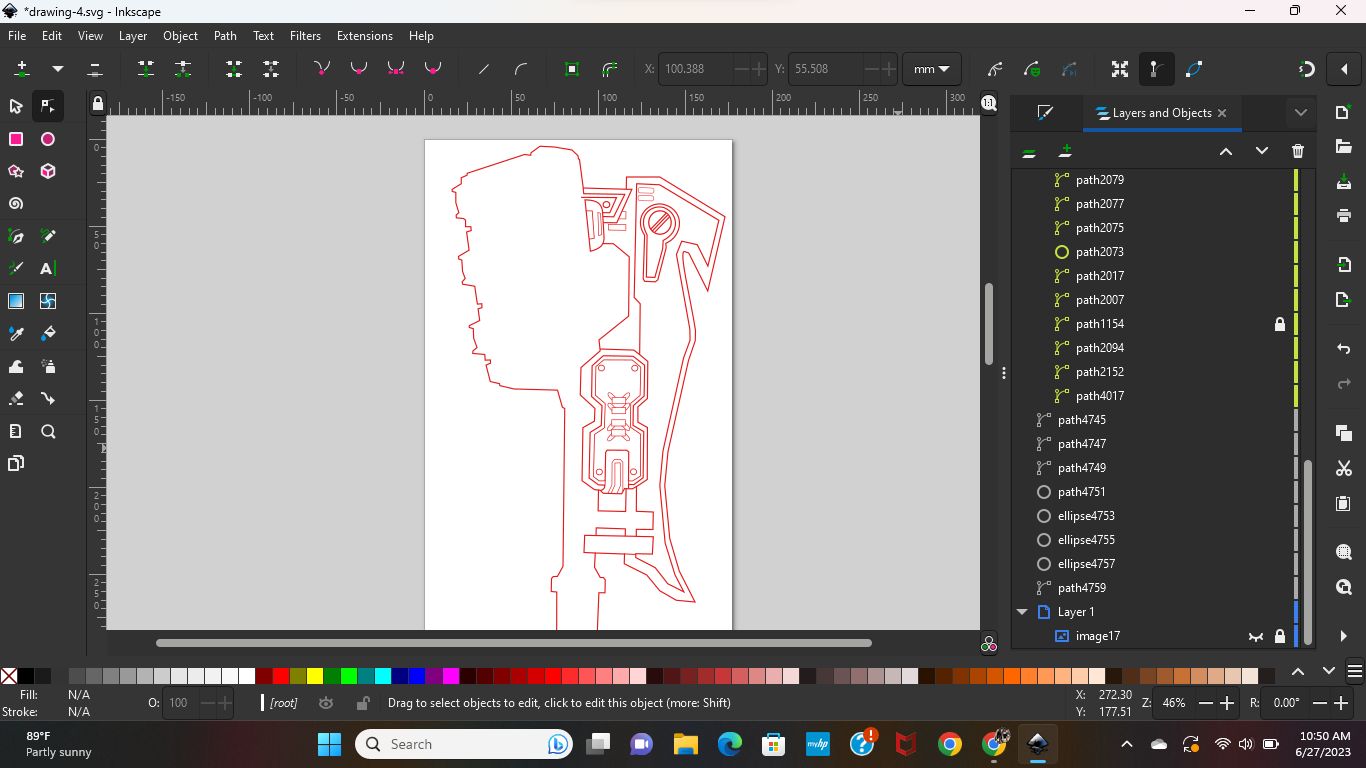

Hi BansheeRose here! I started working on my next Halo build, the Halo 3 Gravity Hammer that I hope to have finished for a convention at the end of July which means I have a lot of work to do. I'm starting by making a flat blueprint on Inkscape, a free software program. I prefer this method because I not only really enjoy using the program but I also learned how to make 3d props from KamuiCosplay on YouTube, and she usually starts with a blueprint, and in the interest of saving time, I decided to use this method rather than Pepakura because there is still a lot for me to learn with translating pepakura to foam. Once I have the pattern done, I'll be printing it on cardstock at home or going to fedex or staples where they can print it out in one go without any seams. For this build I will be using insulation foam, eva floor mat foam, craft foam, and worbla. I want to include electronics but that will probably have to come later after the convention in July. I look forward to sharing this build with the forum since it will be my first time doing so! I'm hoping to get plenty of feedback as I work on this prop since I am trying to learn all I can and level up my cosplaying skills.