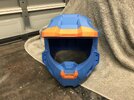

Ok, with all fixes & upgrades to my Dalek now complete I can return my full attention to this build. currently reprinting my helmet to the correct size which turns out to be at 100% of the GA files. the helmet I originally printed at 103% was just a tad too big ... its For Sale in The Marketplace along with the visor buck (printed in PETG) if anyone is interested ...

Its in 2 pieces, front has completed @ 31 hrs & the back is in work (13 hrs) so I'm returning to boots to work on their fit and function checks. I had previously printed the pieces to the correct scale to fit my boots but had done nothing more so first up was to try and connect them via some elastic bands to see if that was functional

at this point I wasn't sure how to attach the armor to my boots but I first needed to see how the static fit was ...

everything looked good and teh boots easily slipped on which was encouraging as I was remembering how difficult my Mando boots are to get on with their costume leather covering glued over the basic boot. however these went on with ease ... so far so good. next came the big test which was to walk around normally and see what happened.

to my great surprise not only could I walk normally in them but the boot armor stayed in place without any attachments. Given this result it looks like was good to move on to the next phase which is to disassemble the boot armor & proceed to making molds of each piece so I can cast it in a slightly more flexible resin. In all likelihood I'll add velcro to ensure the armor boots stay fixed to the real boots and also insert some foam where their is space which should keep everything together

For those who have be following along you may recall that my cunning plan is to cast my armor in this semi flexible resin like the GA boys are now doing with their Helldiver armor they sell. this will should make the armor much more wearable while still being durable. The GA boys threw their new armor off the 2nd floor of their shop and threw it on the ground with no issue ...

Of course the real fun now is how to make molds for each armor pieces ... I've got plenty of experience in basic mold making techniques from creating the full head silicon mask for my Cooper Howard outfit so I've got teh basics down but I may need to rotocast some parts or use other mold making techniques ... we'll see.

In 2 days I leave for the British Isles & Norway for a month so all I'll be doing is more researching and watching lots of Smooth-On How-to videos. I work as one of Viking Cruises Resident Astronomers and so there will be plenty of time during these 2 cruises to watch videos. Hopefully, therefore I'll have figured out enough that I can jump straight into mold making for the boot parts right after I return ... that's my cunning plan anyway ...

Any comments, suggestions and tips from experienced mold makers are welcome ...