fiberglass is thin sheets/strips of a strong fiber infused with glass (which is why it hurts if you get them stuck in your fingers). this is essentially useless though without fiberglass

RESIN. fiberglass resin is a chemical mix that you put on the shell of your cardstock build. you then use fiberglass RESIN as a extremely strong adhesive that fuses the fiberglass matt or cloth to the interior of the armor piece.

The reason people say pieces may warp is before you do the fiberglass cloth, it is suggested to put a layer or 2 of fiberglass resin on the outside of the pep piece to give it a stronger structure. though it won't have any actual reinforcement just rigidness (this is why you have to put fiberglass cloth or matt on the inside). This is why it is suggested to use popsicle sticks or something on the inside of armor pieces before doing the fiberglass resin coat.

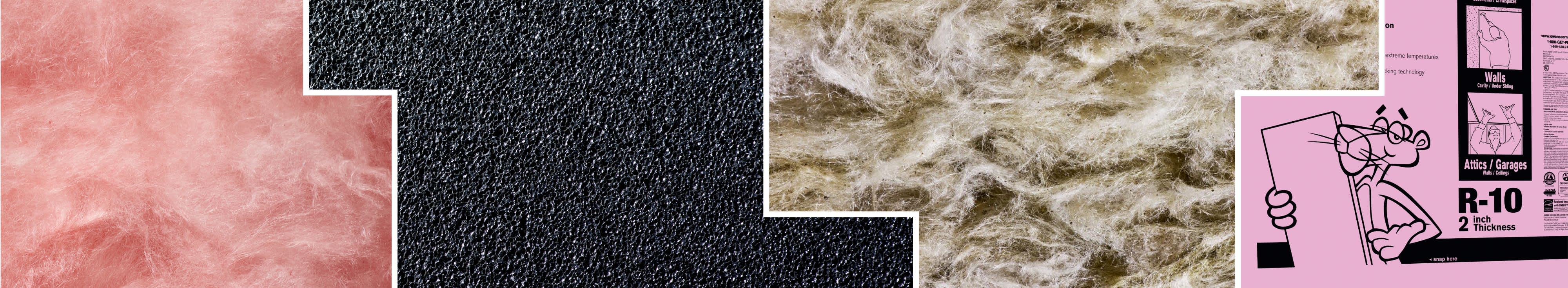

this is fiberglass cloth:

View attachment 289152

this is fiberglass resin (a liquid that you use hardnerer to create it into an adhesive thing):

View attachment 289153

Bondo is the last step: bondo you slop on the whole piece and then sand it down to give it a smooth surface and you can add details to it as well.