indiefilmgeek

New Member

More old electronics have given their lives for the Voice System in Mikey's Ironman Helmet.

First up... An old gaming headset with a boom mic... I grabbed the boom mic and scrapped the rest.

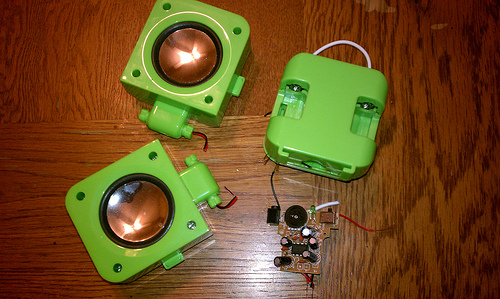

Next up... One of many battery-powered external speaker sets for ipads and such. It's got a small amp, but it comes with a power button and volume control. Circuit board and speakers kept -- everything else chucked!

I spent last night installing the boom mic and then connecting it to the voice-changer board (and 9v). The speaker output from the voice-changer now exits to the external speaker board (which gives me power and volume control (while adding a little bit of further amp). All the parts are now wired and installed in the helmet.

Video Tour of the new additions:

*again, I have to apologize for the crappy audio... I'm not sure what's up with my EVO, but the mic has sure been jacked up lately. You can hear how bad my voice sounds throughout, so it's not just the cheap speaker I'm using in this demo... it's my camera phone's mic.

First up... An old gaming headset with a boom mic... I grabbed the boom mic and scrapped the rest.

Next up... One of many battery-powered external speaker sets for ipads and such. It's got a small amp, but it comes with a power button and volume control. Circuit board and speakers kept -- everything else chucked!

I spent last night installing the boom mic and then connecting it to the voice-changer board (and 9v). The speaker output from the voice-changer now exits to the external speaker board (which gives me power and volume control (while adding a little bit of further amp). All the parts are now wired and installed in the helmet.

Video Tour of the new additions:

*again, I have to apologize for the crappy audio... I'm not sure what's up with my EVO, but the mic has sure been jacked up lately. You can hear how bad my voice sounds throughout, so it's not just the cheap speaker I'm using in this demo... it's my camera phone's mic.