NobleofDeath16 requested that I make this so I'm going to now.

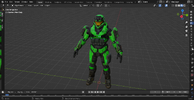

So I am making a Mark V B armor pulled straight from Halo Reach. Most stuff will be foam BUT the Shoulder, helmet and weapons will be 3d printed here it is in Blender.

I'm really leaning in on green with black here, I think it looks sick. Thoughts anyone?

So I am making a Mark V B armor pulled straight from Halo Reach. Most stuff will be foam BUT the Shoulder, helmet and weapons will be 3d printed here it is in Blender.

I'm really leaning in on green with black here, I think it looks sick. Thoughts anyone?