VerdantTrash

New Member

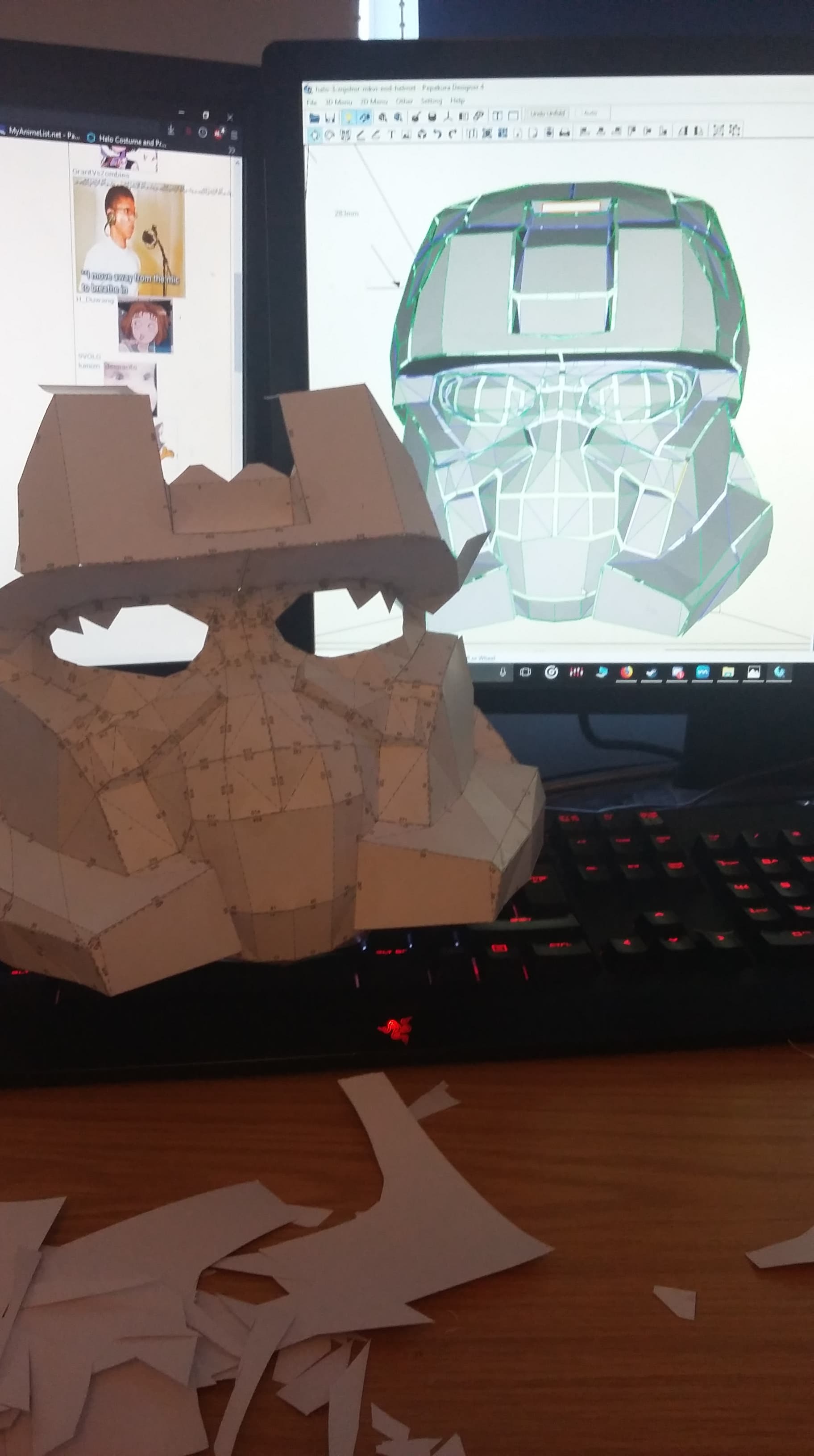

So I've been wanting to make some halo amour for YEARS. I've only just now been able to bring myself to spend the next few months making pepakura. My initial idea was a CQB suit, however I had some other ideas.

I thought I could make it modular. I could have the chestplate removable and make different helmets and shoulders.

So after attempting to make the CQB helmet twice I decided I'd try a different helmet. So after a week of staring at photos of MK V permutations, I decided on EOD.

So here begins the pepakura stage, as huge wads of templates and odd shapes come flying out of my printer in the form of card stock.

The helmet started good. No issues other than a minor lack of detail.

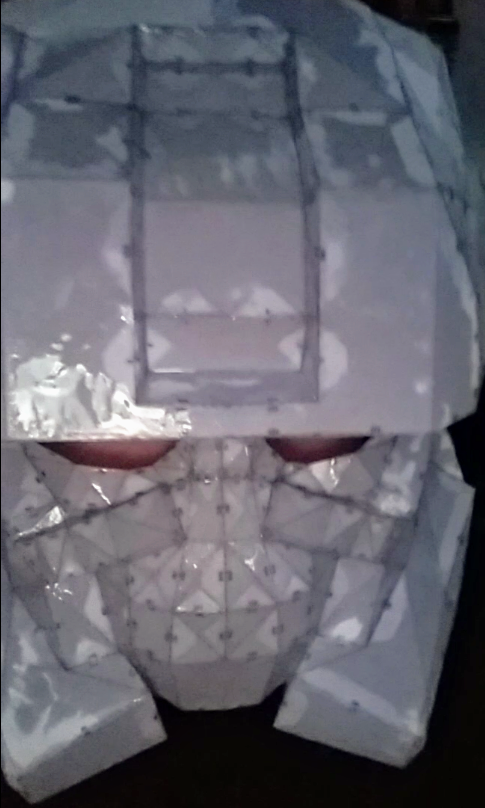

So I move on to hardening! The big scary step that I've never done before.

So I hardened a glove panel first to test.

Oh no. It's a brick. Note to self, apply thin.

So I move on to the helmet with the epoxy I have left.

It turned out pretty good and I'm really impressed with the resin.

Next I will use fibreglass!

I thought I could make it modular. I could have the chestplate removable and make different helmets and shoulders.

So after attempting to make the CQB helmet twice I decided I'd try a different helmet. So after a week of staring at photos of MK V permutations, I decided on EOD.

So here begins the pepakura stage, as huge wads of templates and odd shapes come flying out of my printer in the form of card stock.

The helmet started good. No issues other than a minor lack of detail.

So I move on to hardening! The big scary step that I've never done before.

So I hardened a glove panel first to test.

Oh no. It's a brick. Note to self, apply thin.

So I move on to the helmet with the epoxy I have left.

It turned out pretty good and I'm really impressed with the resin.

Next I will use fibreglass!

Last edited: