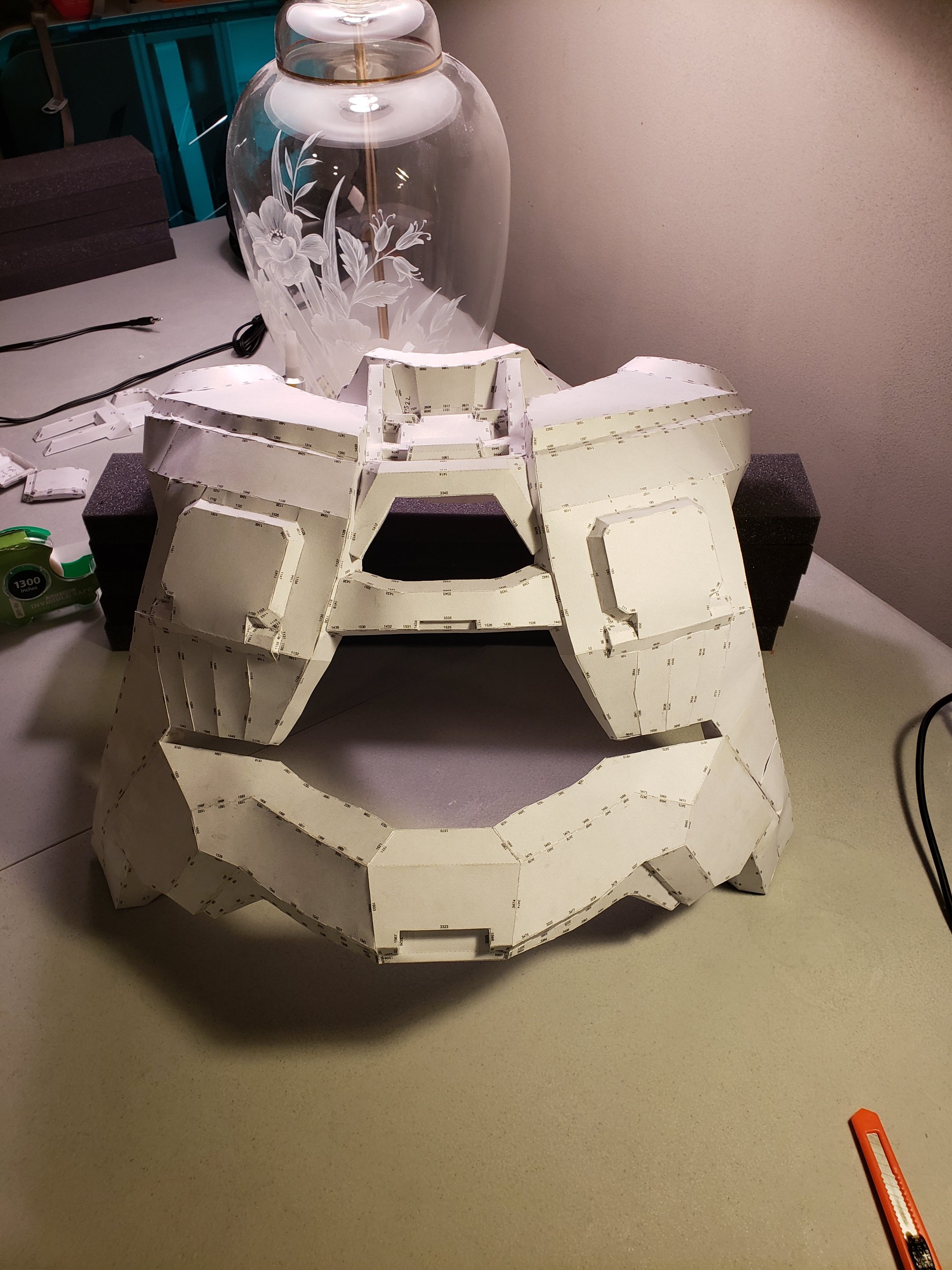

Over the last couple months I've been slowly working through the pep part of my chief build. I am currently sitting with the torso pep files complete and am starting to harden and bondo.

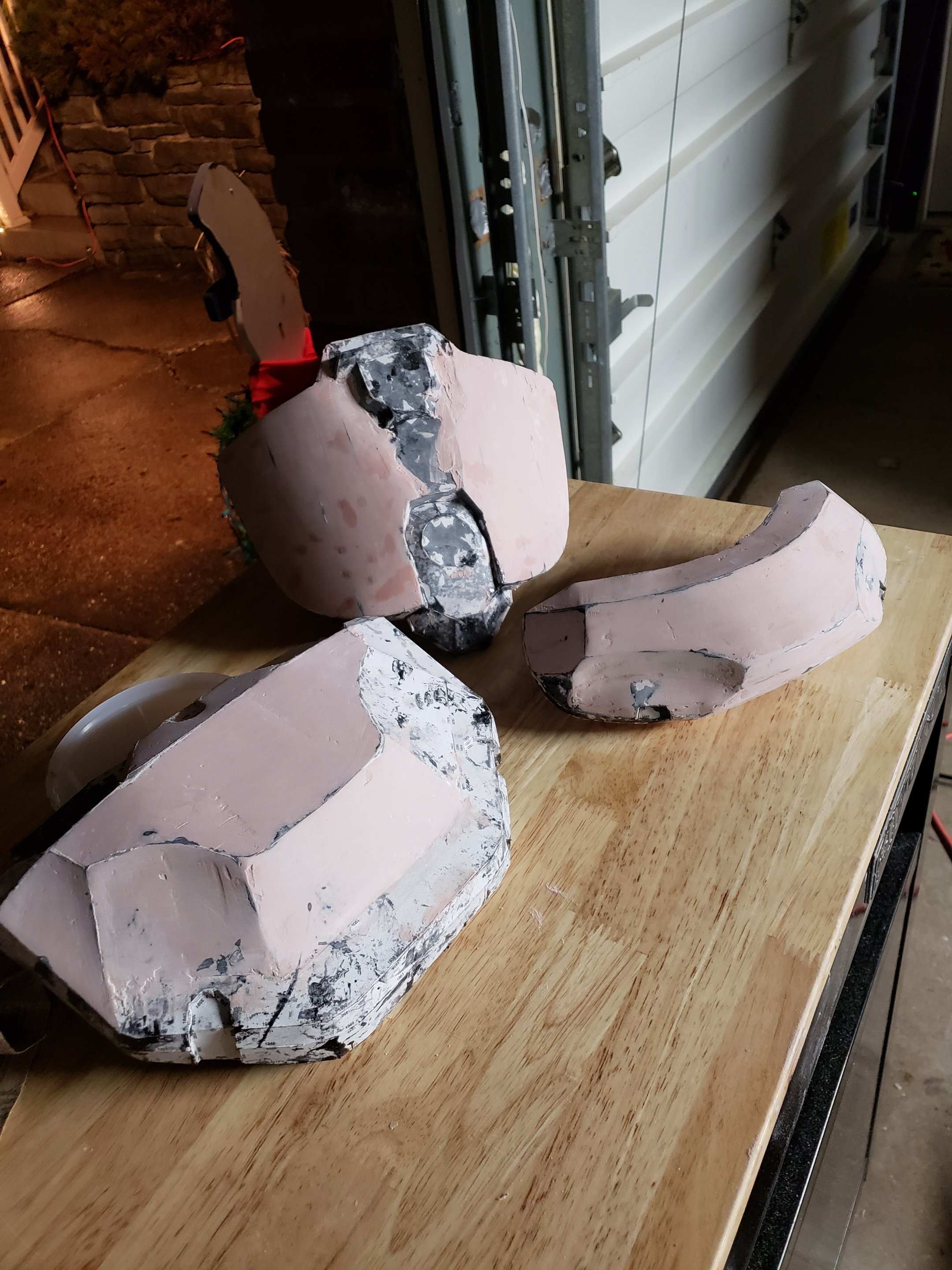

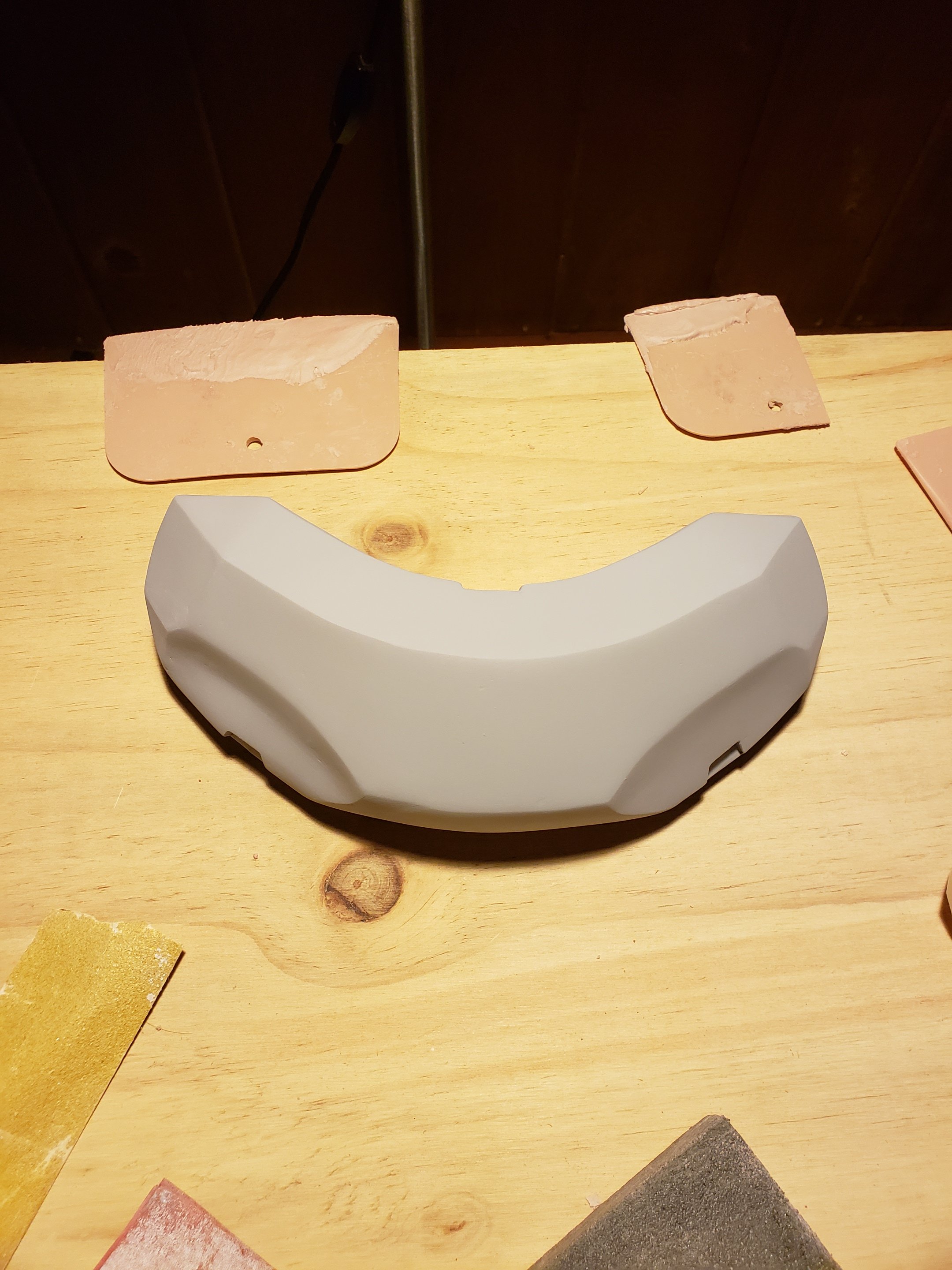

The first helmet I started was warped as you will be able to see below so i'm thinking of scraping it and restarting. it was kind of the test subject to see what processes of hardening I want to use and it was kind of a flop, but I learned a lot so it wasn't a complete waste of time. Any tips or help is greatly appreciated.

enjoy

The first helmet I started was warped as you will be able to see below so i'm thinking of scraping it and restarting. it was kind of the test subject to see what processes of hardening I want to use and it was kind of a flop, but I learned a lot so it wasn't a complete waste of time. Any tips or help is greatly appreciated.

enjoy