- Member DIN

- S068

First big update for these two projects. I have been working to get the obj files for the recruit armor to be printable. However, as I have never done 3d modeling and am a noob at 3d printing, it's progressing very slowly. I did decide to go full on screen accurate with my files as well, so I am having to add details to them, which is slowing the process down to a CRAWL. However, I have made more progress with my printing.

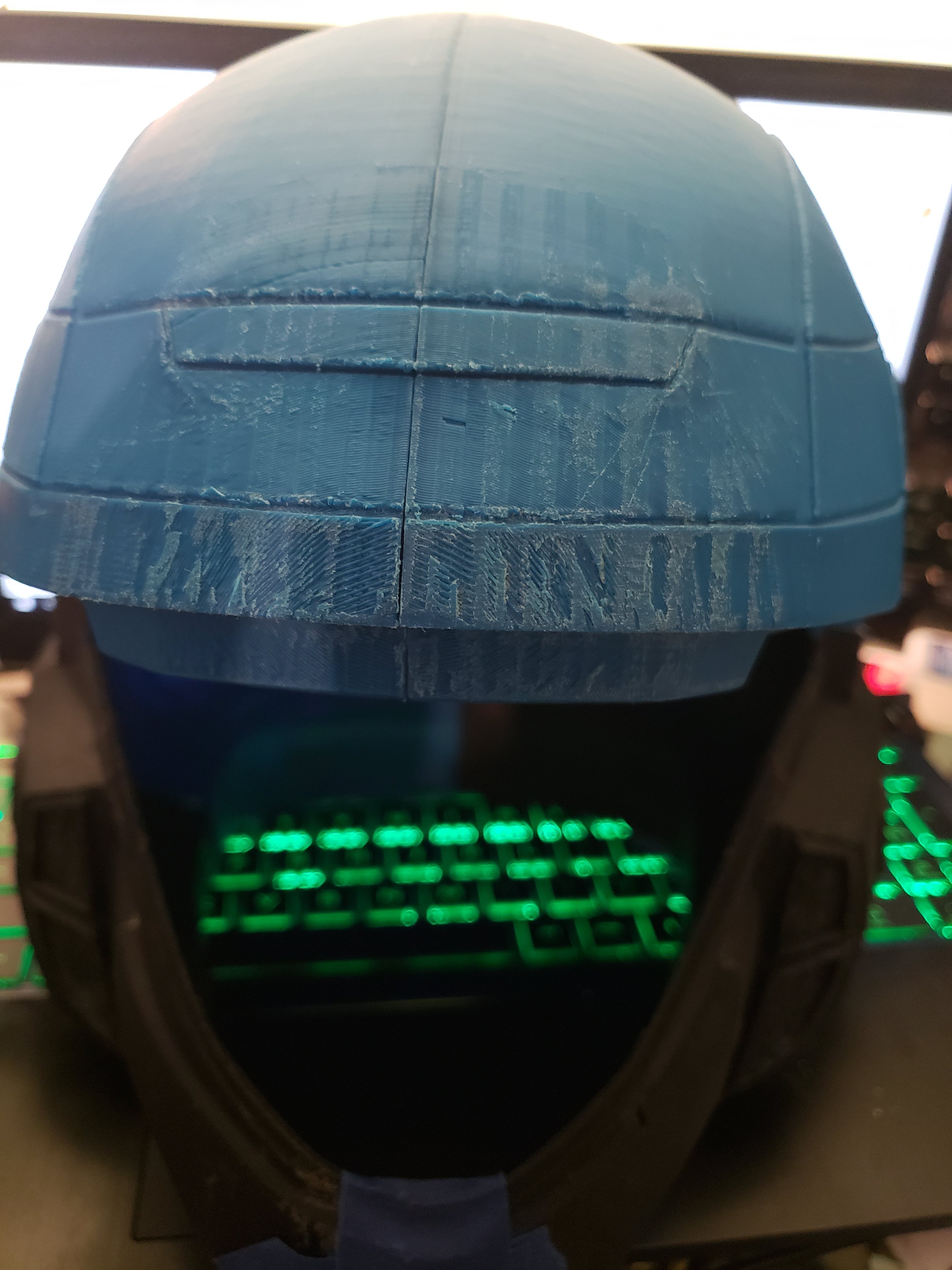

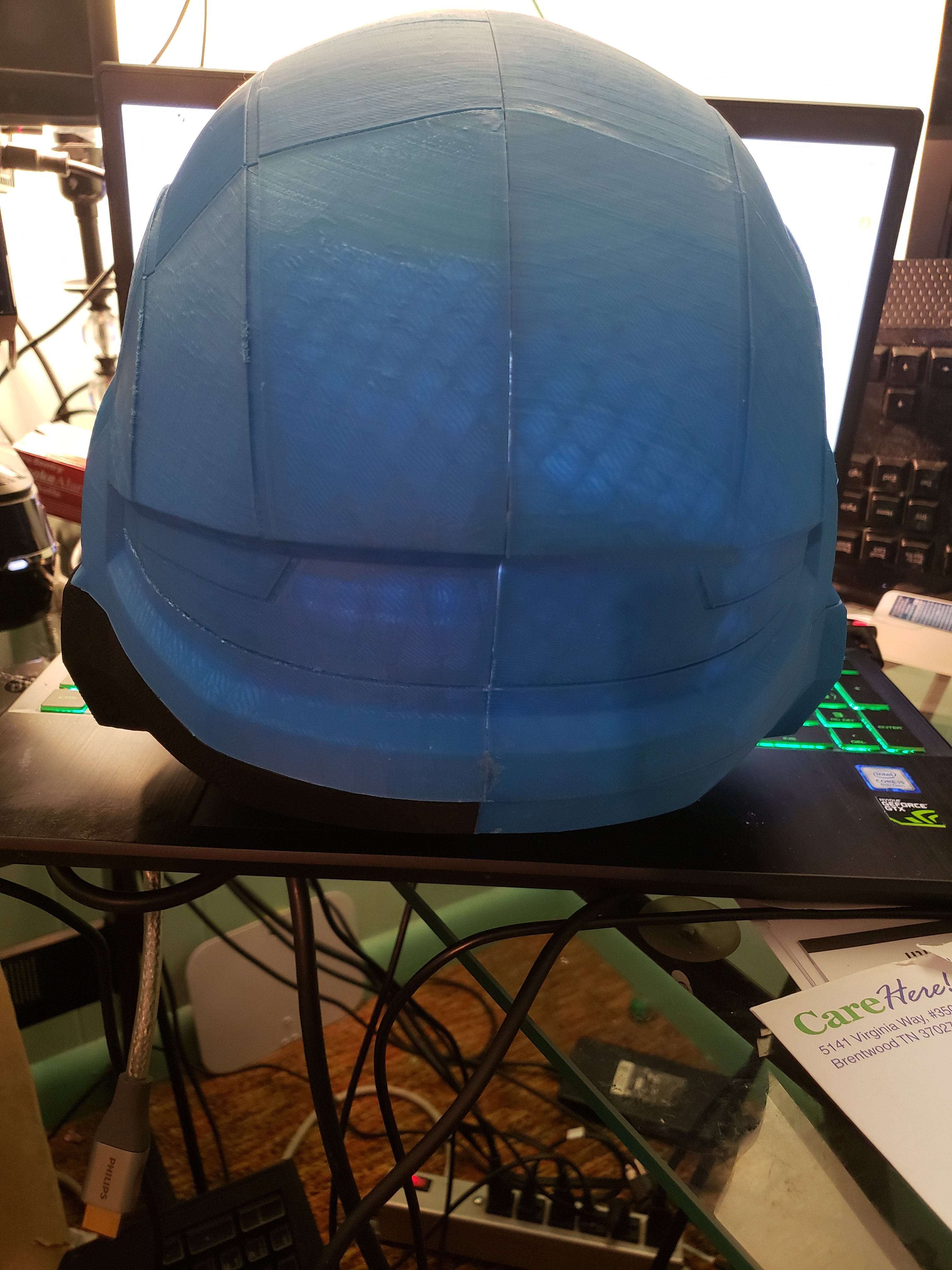

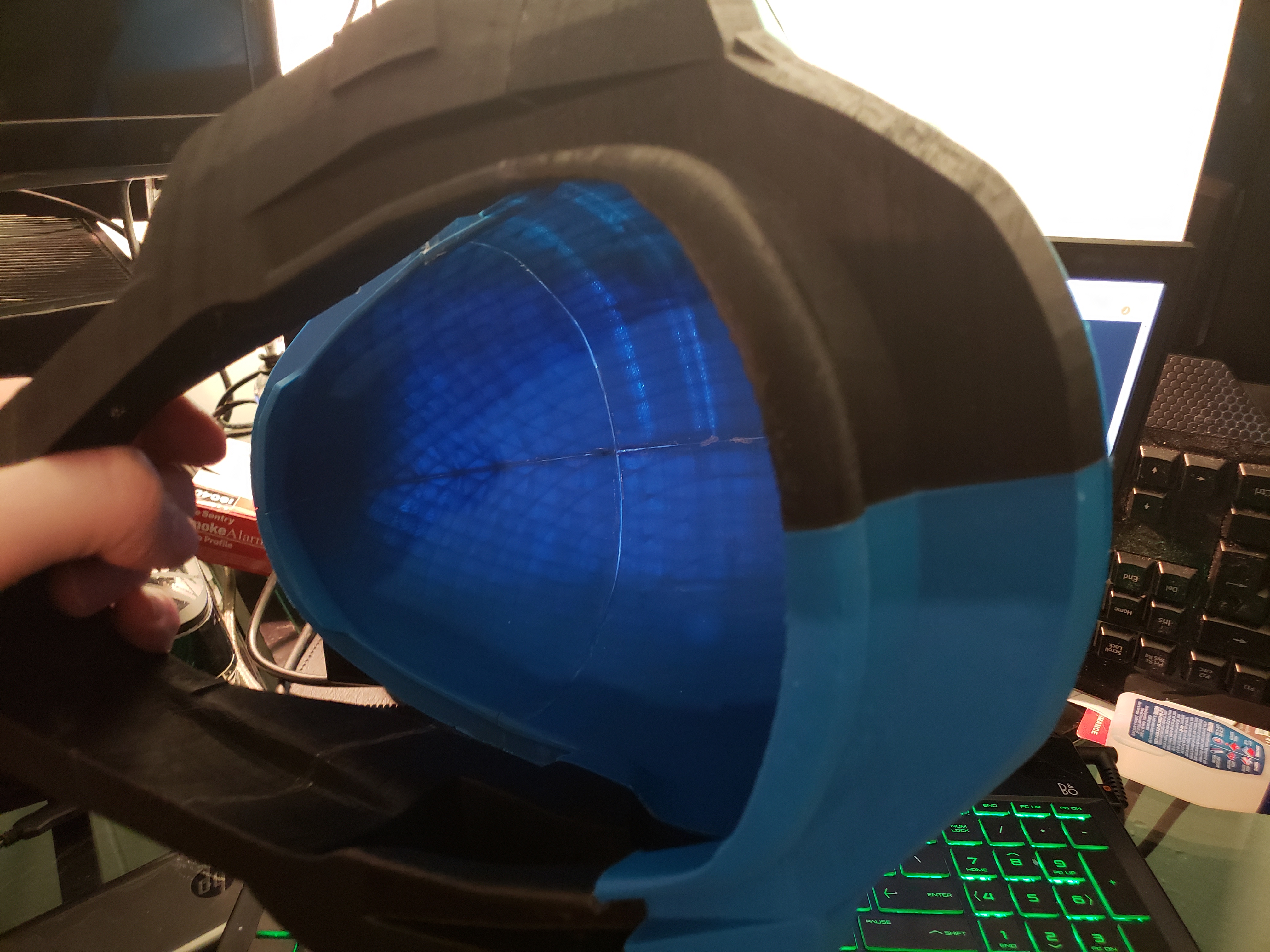

I have completely printed the Halo 3: ODST helmet.

However, I have not been able to actually try it on yet now that it's fully glued together.

I really like the detail of the neck seal, and I want to figure out how to keep it, but it means that right now I can't get it on my head.

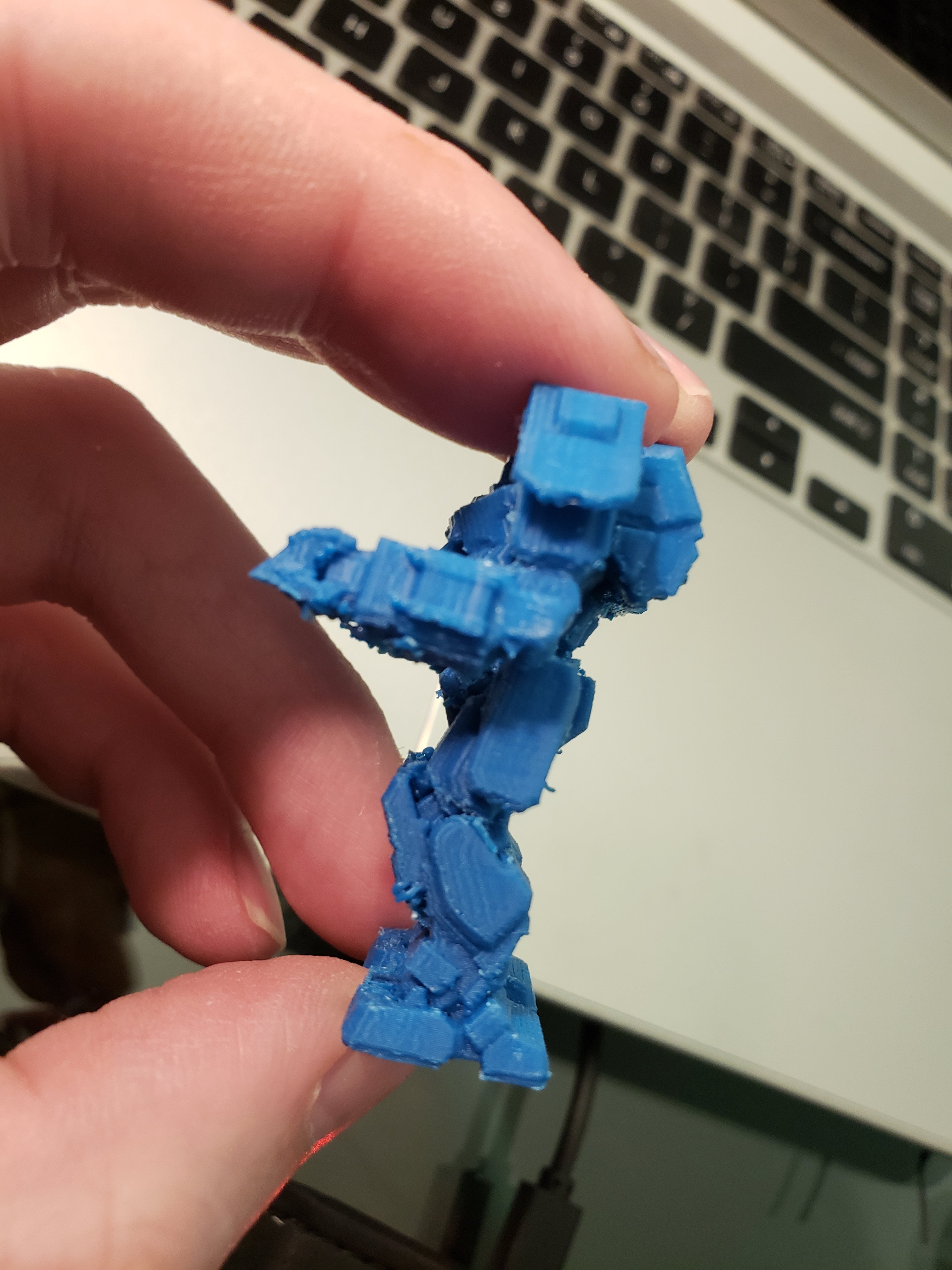

In other news, though, I successfully printed the reason I decided to go with an ODST...

I love the way that turned out. My glue job was less than perfect, so there are so offset seams, but overall I'm excited about it.

On the printer front, and one of the main reasons I've only gotten this much printed, is I have run into some difficulties with my printer. It will drift out of level by about the 5th build, and does not have an auto-level, so I have to spend a couple hours every other day releveling it. It also meant that I had a few failed prints on the helmet, hence the shift to black for the last 1/3. I am planning on adding a bed leveler to it to speed up the process. That being said, I have no complaints about the printer. The quality of the prints has been outstanding, even as small scale, as least as far as I've been able to tell. Judge for yourself, though.

Any ideas on why the printer is losing it's level plane?

On the Tevo Tornado and several other printers the bed leveling is controlled by four adjustment screws that grip onto the glass bed. Unfortunately metal and glass doesn't have an outstanding amount of friction and screws slip over time. Just add in a rubber washer and bed adjustment becomes far less frequent.