ok, im new to this forum,

and pepakura... so the first model i made was a halo 2 odst... it turned out good, but when i used a special paper machey, it warped it...

and pepakura... so the first model i made was a halo 2 odst... it turned out good, but when i used a special paper machey, it warped it...

my next try was a recon helmet, it worked out nicely, and i painted it... visit my youtube channel to see pics (619deathstar)

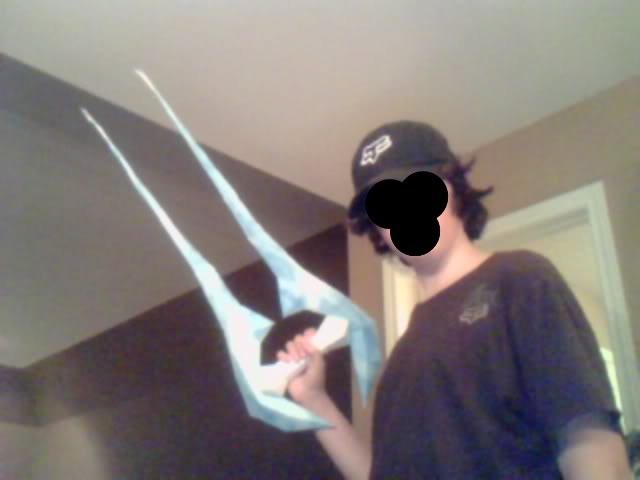

and i just finished the pepakura verson of my energy sword, i hope you like it =D

thats what i got soo far, and also is there anny suggestions on how i should go about hardening this?

I have conissered using plaster strips, then maby fiberglass?

my next try was a recon helmet, it worked out nicely, and i painted it... visit my youtube channel to see pics (619deathstar)

and i just finished the pepakura verson of my energy sword, i hope you like it =D

thats what i got soo far, and also is there anny suggestions on how i should go about hardening this?

I have conissered using plaster strips, then maby fiberglass?