Satchmo III

Well-Known Member

Hail four-oh-five!

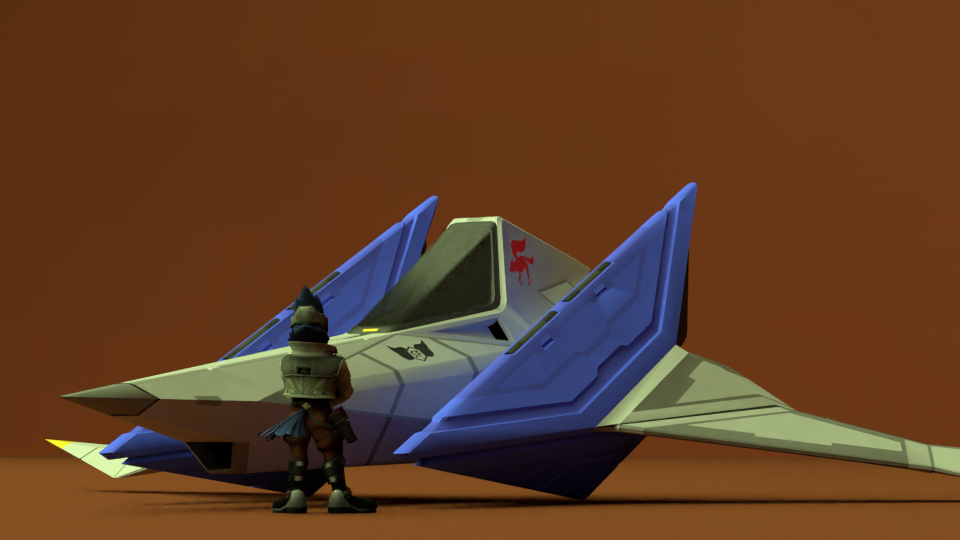

This thread will document the making of a physical model arwing from the 3ds remake of Star Fox 64.

Arwings from other Star Fox games may be added to the build as work progresses (likely the SNES and Star Fox 64 versions at minimum). I know this isn't Halo-related but I'm sure there are some Star Fox fans on the forums that may appreciate the build. I've been doing quite a bit of 3D modeling as of late but I haven't built anything for some time...so I'm changing that.

Thanks for your interest and please post any questions or comments. Wish me a (garbled) good luck!

I've reserved the next post for finish photos.

This thread will document the making of a physical model arwing from the 3ds remake of Star Fox 64.

Arwings from other Star Fox games may be added to the build as work progresses (likely the SNES and Star Fox 64 versions at minimum). I know this isn't Halo-related but I'm sure there are some Star Fox fans on the forums that may appreciate the build. I've been doing quite a bit of 3D modeling as of late but I haven't built anything for some time...so I'm changing that.

Thanks for your interest and please post any questions or comments. Wish me a (garbled) good luck!

I've reserved the next post for finish photos.

Last edited: