Jeff Torres

Member

Ok, I first I want to Apologize to the 405th for making So many Hidden Blade Related Topics, But It was spread out across several Identical W.I.P.s dedicated to all the same thing, The Assassins Creed Hidden Blade. Part of that Was that I wanted to express my Ideas to you all, and partly because I've thought a a completely Different method to creating the way and so the previous thread was not relevant...I apologize for my Far too many Threads.

That being said I want to kick this project off with some Knowledge.

http://www.405th.com/showthread.php/26763-Slider-Phone-Question

This is a ANOTHER thread I had started asking about the slider phone Mechanism...plus some Comedy..(Its ok HeavyGunner! You handled it well! lol)

http://www.youtube.com/results?search_query=Assassins+creed+Hidden+Blade&aq=f

click on one and it will show many more suggestions on the hidden blade just to show you actually how many people tried this

http://media.photobucket.com/image/H...s/S6301749.jpg

same picture from within the second paragraph

the Assassins Creed 2 Trailer...the hidden blade plus gun

the Hidden Blade I will be replicating...plus an awesome trailer for an awesome game!

---------------------------------------------------------------------------------------

Ok now I will continue onto my W.I.P.

This project started out whilst looking into the hidden blade, I was going to buy the commercial version

(this guy isnt me...he will not respond to my requests on some high resolution pics of the workings...)

I've been able to find some pics since then, to Exotic Automatic.com and you have to sign on to be able to look at the take-apart of the commercial version.

And I'm making 2 blades...mirror versions of each other, thats why the Slider is 9 inches...because each will be actually 4.5 inches. The base will be made out of Aluminum, and will be 10.5 inches long. or Roughly 23 inches (I like room to work, screwups or whatnot)

Day One of the Project:

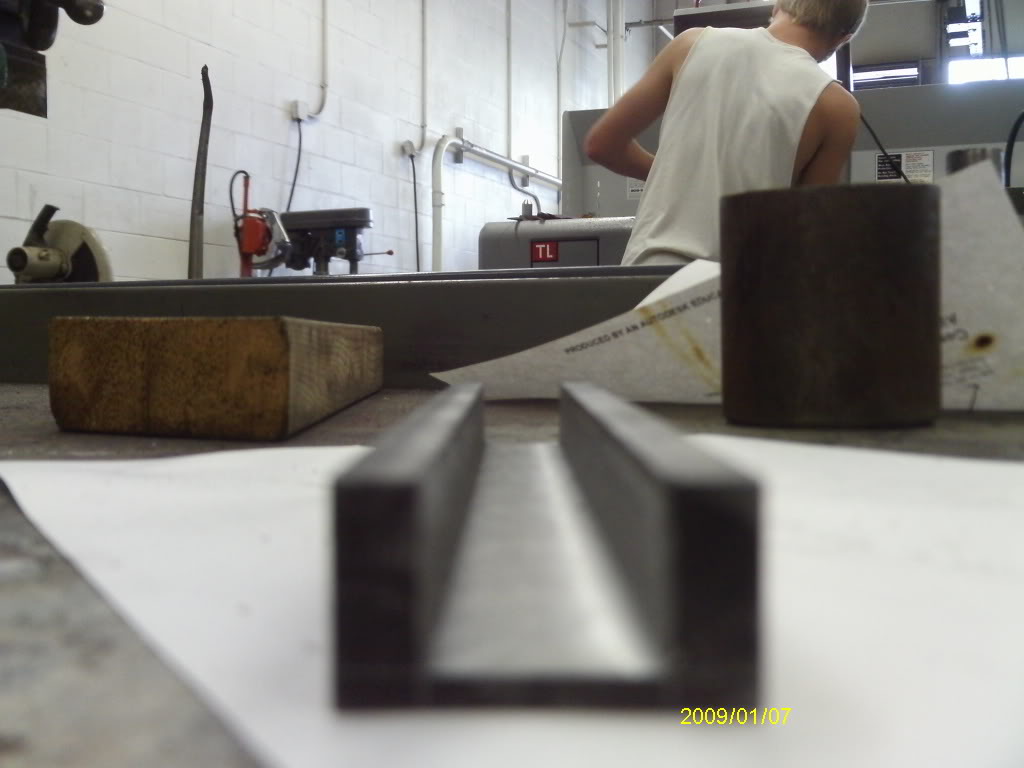

Milled down the Sides and top/bottom with a milling machine from a 1x1x9 piece of stock to a 3/4 by 1 3/8 piece of metal.

Day 2:

Slot cut into the "Slider" so it can be made to accept the piece of Conduit piping (For the scabbard, the middle section just after the blade)

It will be flattened Further with either a torch (thin metal...maybe) or a hammer.

And My trusty Milling Machine..equipped with 80's era CNC Technology..but all I need is the "JOG" Feature. All it has are the X and Y axis's (Forward and backward, side to side)...forget the Z axis (up and down).

I want to do some of the work anyway

That being said I want to kick this project off with some Knowledge.

http://www.405th.com/showthread.php/26763-Slider-Phone-Question

This is a ANOTHER thread I had started asking about the slider phone Mechanism...plus some Comedy..(Its ok HeavyGunner! You handled it well! lol)

http://www.youtube.com/results?search_query=Assassins+creed+Hidden+Blade&aq=f

click on one and it will show many more suggestions on the hidden blade just to show you actually how many people tried this

http://media.photobucket.com/image/H...s/S6301749.jpg

same picture from within the second paragraph

---------------------------------------------------------------------------------------

Ok now I will continue onto my W.I.P.

This project started out whilst looking into the hidden blade, I was going to buy the commercial version

I've been able to find some pics since then, to Exotic Automatic.com and you have to sign on to be able to look at the take-apart of the commercial version.

And I'm making 2 blades...mirror versions of each other, thats why the Slider is 9 inches...because each will be actually 4.5 inches. The base will be made out of Aluminum, and will be 10.5 inches long. or Roughly 23 inches (I like room to work, screwups or whatnot)

Day One of the Project:

Milled down the Sides and top/bottom with a milling machine from a 1x1x9 piece of stock to a 3/4 by 1 3/8 piece of metal.

Day 2:

Slot cut into the "Slider" so it can be made to accept the piece of Conduit piping (For the scabbard, the middle section just after the blade)

It will be flattened Further with either a torch (thin metal...maybe) or a hammer.

And My trusty Milling Machine..equipped with 80's era CNC Technology..but all I need is the "JOG" Feature. All it has are the X and Y axis's (Forward and backward, side to side)...forget the Z axis (up and down).

I want to do some of the work anyway

Last edited by a moderator: