LightningWaffle

New Member

Morning 405th. I've been holding off on posting up a thread for the sake of having more progress to post, and after last night's work, I decided to post up my progression on Jorge's armor.

I actually tried my hand at pepping about a year ago. I made a Halo 3 marine helmet, and had it down to the Rondo stage before it was accidentally smashed by my roommate (I am a college student, just to let you know). I don't have a roommate this year, which makes this hobby a bit easier. Anyways, here's what I've got after a week and a half, on and off, of pepping.

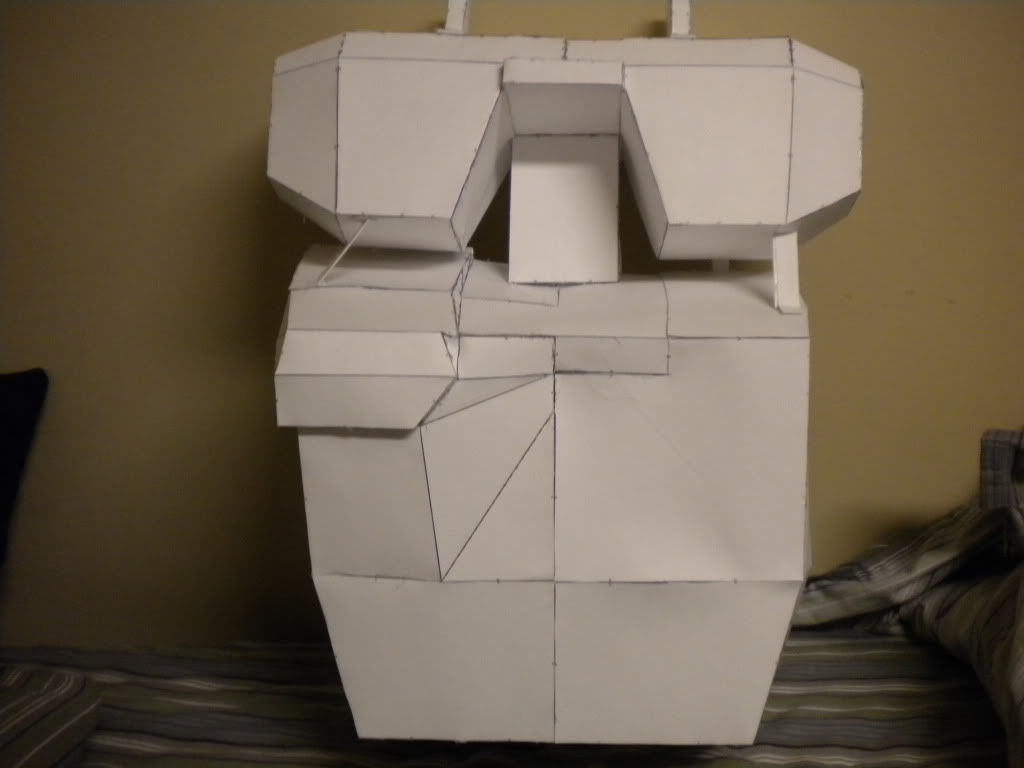

The backpack, just completed, with support pieces.

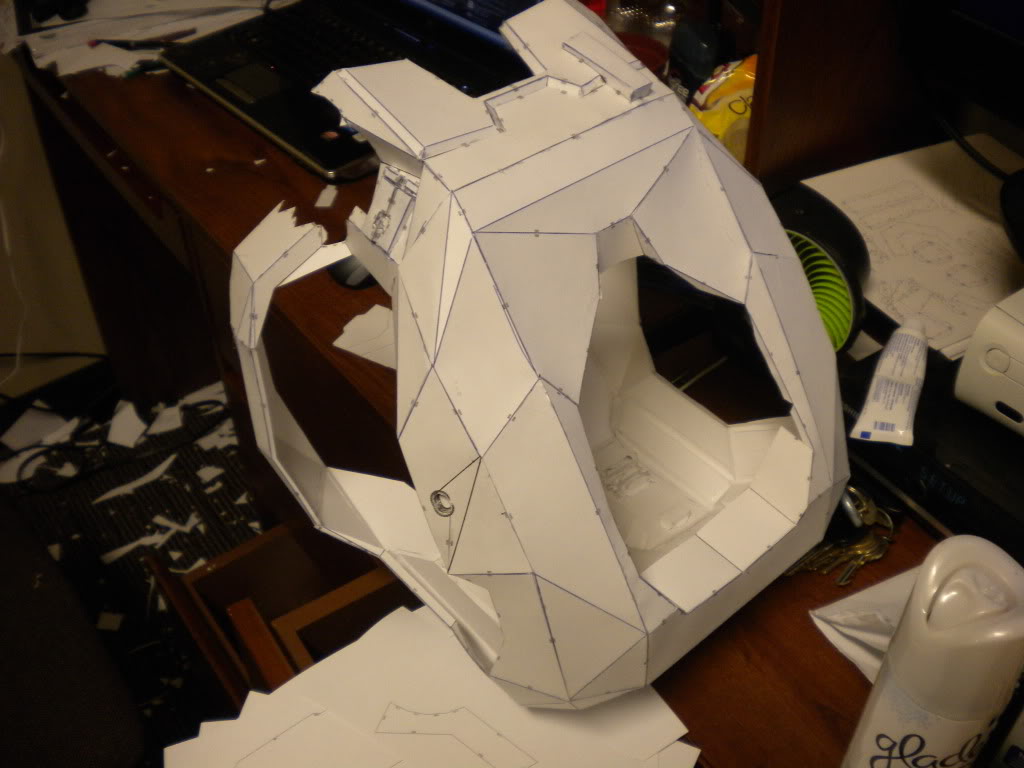

The grenadier collar, in a partial stage of completion. Note that on my laptop I was actually reading around on the forums at the time of the picture.

Five hours later, the finished result. Note that I left the flap open on the UA attachment so I could Rondo the inside.

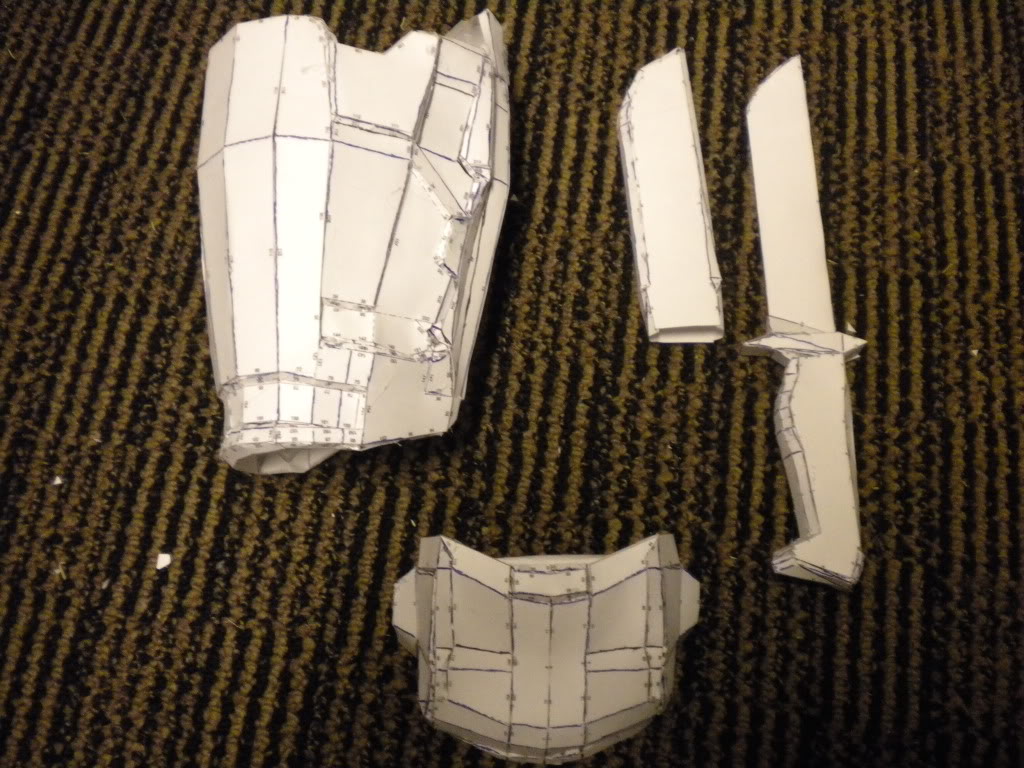

Very early on in the project, I finished the boot toe, a forearm, and a knife.

My total project compilation as of the time of posting.

Well, that's all the photos I have at the moment. Let me know what you guys think, and I'll keep you updated. I just got the go-ahead to start resining and fiberglassing (they wouldn't allow any of it in or around the dorms until I got the ok), so that's part of my starting project today.

I actually tried my hand at pepping about a year ago. I made a Halo 3 marine helmet, and had it down to the Rondo stage before it was accidentally smashed by my roommate (I am a college student, just to let you know). I don't have a roommate this year, which makes this hobby a bit easier. Anyways, here's what I've got after a week and a half, on and off, of pepping.

The backpack, just completed, with support pieces.

The grenadier collar, in a partial stage of completion. Note that on my laptop I was actually reading around on the forums at the time of the picture.

Five hours later, the finished result. Note that I left the flap open on the UA attachment so I could Rondo the inside.

Very early on in the project, I finished the boot toe, a forearm, and a knife.

My total project compilation as of the time of posting.

Well, that's all the photos I have at the moment. Let me know what you guys think, and I'll keep you updated. I just got the go-ahead to start resining and fiberglassing (they wouldn't allow any of it in or around the dorms until I got the ok), so that's part of my starting project today.