First off, I'd like to say "Hi" to all you "four-o-fivers"! The water's nice and warm!

Anyway, I've been lurking around here for about a month now. Reading, and reading, and reading. As I started my project I hadn't even heard of this site, but my research brought me here and I'm glad. This community cranks out some quality work, and the collaboration is amazing. Enough of this and on to why I'm here.

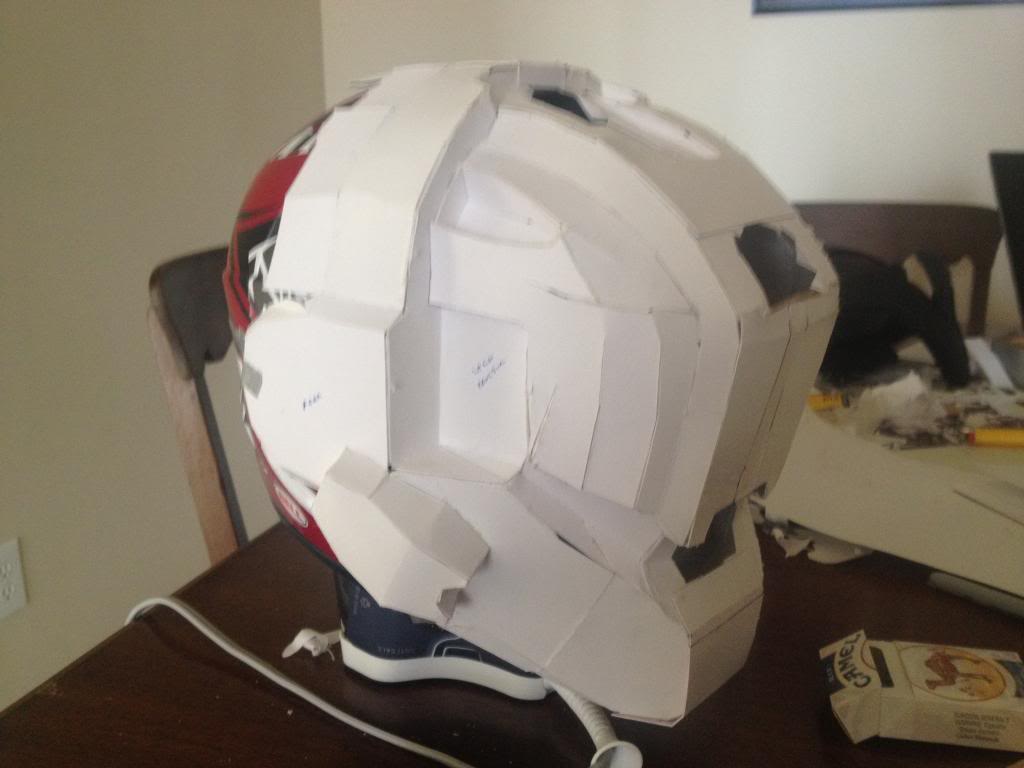

Bam

What you see there is an early "Militia Helmet" from Titanfall and is most definitely a "WIP" and it will be, for a while. The end result will be "production grade". As this is not a debate, the word "ambitious" will remain in the title.

I bought the child's full-faced motorcycle helmet before discovering pepakura and decided to meld the two. The result will be a strong and symmetrical piece with minimal struggle. The Scope of Work for this project is extensive. Knowing this is a hobby and not having to meet any kind of deadline gives me the time to precisely plan out everything, funds being allocated as needed, so, the sky is the limit. The end product will have a manufactured look, paying as much attention to the inside as out. LED's, spotlights, strobe light, fan, and iphone integration. I'm putting tactile buttons for everything as well as the phone in a wristpad. Batteries will be housed in the "Jump Kit" mounted on my lower back. After viewing many, many Iron Man builds, and buffing up on some kinematics, I've designed a way for the faceplate to open in three pieces and fold back. I've gone so far as to pep a second face shield to serve as a Proof of Concept.

Ok. That's all for right now. After I cover the plastic with paper, I'll be ready for resin by Saturday, and I'll be bondoing some small accessories to test my methods. I'm going on everything I've read from you wonderful people, so I'll let you know how it goes as much as I can. I do have a full time job that sometimes requires my work to come home with me.

*sorry for potato

Let me know what you think. Criticism is warmly welcomed.

Anyway, I've been lurking around here for about a month now. Reading, and reading, and reading. As I started my project I hadn't even heard of this site, but my research brought me here and I'm glad. This community cranks out some quality work, and the collaboration is amazing. Enough of this and on to why I'm here.

Bam

What you see there is an early "Militia Helmet" from Titanfall and is most definitely a "WIP" and it will be, for a while. The end result will be "production grade". As this is not a debate, the word "ambitious" will remain in the title.

I bought the child's full-faced motorcycle helmet before discovering pepakura and decided to meld the two. The result will be a strong and symmetrical piece with minimal struggle. The Scope of Work for this project is extensive. Knowing this is a hobby and not having to meet any kind of deadline gives me the time to precisely plan out everything, funds being allocated as needed, so, the sky is the limit. The end product will have a manufactured look, paying as much attention to the inside as out. LED's, spotlights, strobe light, fan, and iphone integration. I'm putting tactile buttons for everything as well as the phone in a wristpad. Batteries will be housed in the "Jump Kit" mounted on my lower back. After viewing many, many Iron Man builds, and buffing up on some kinematics, I've designed a way for the faceplate to open in three pieces and fold back. I've gone so far as to pep a second face shield to serve as a Proof of Concept.

Ok. That's all for right now. After I cover the plastic with paper, I'll be ready for resin by Saturday, and I'll be bondoing some small accessories to test my methods. I'm going on everything I've read from you wonderful people, so I'll let you know how it goes as much as I can. I do have a full time job that sometimes requires my work to come home with me.

*sorry for potato

Let me know what you think. Criticism is warmly welcomed.