vegas vader

New Member

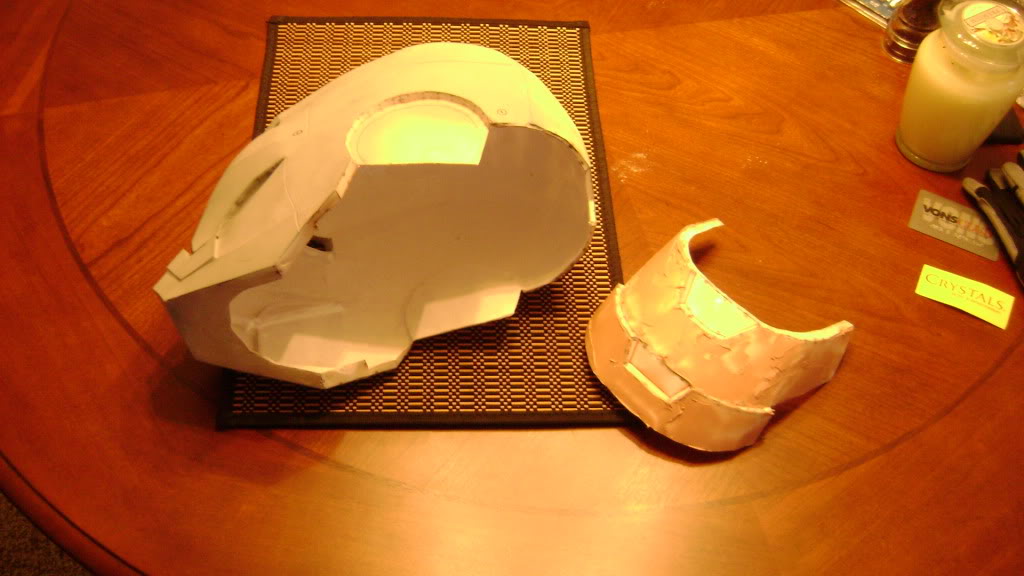

i dunno if you are all tired of seeing Iron Man helmets being made, but i am here to show my progress so far the helmet is originally scaled to 265cm i have a 24 inch head the helmet fits me perfectly. and it was so easy to put together.

the helmet is originally scaled to 265cm i have a 24 inch head the helmet fits me perfectly. and it was so easy to put together.

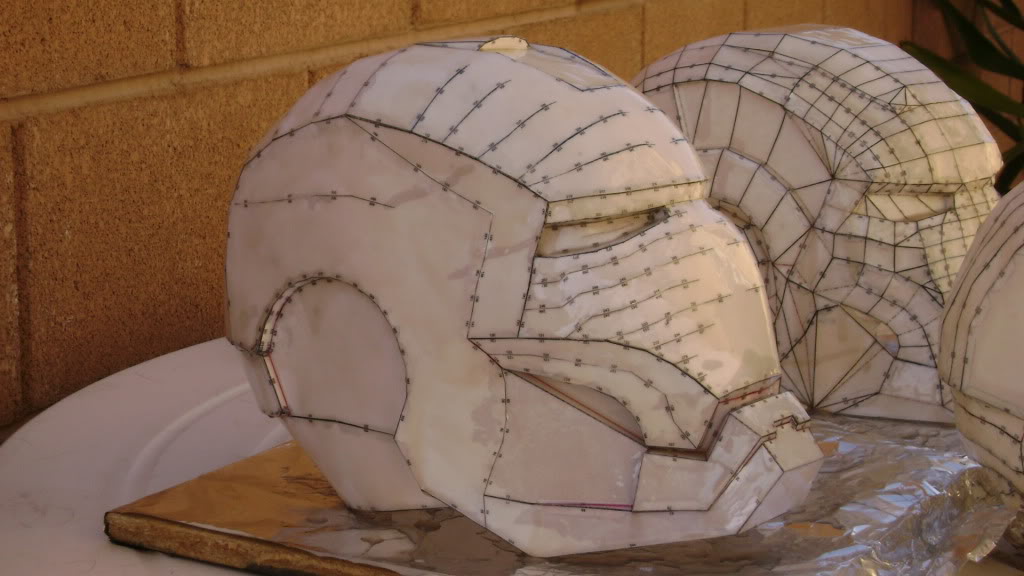

i reinforced the helmet by adding smooth cast 320 to further reinforce the helmet. the amazing thing about this type of resin is that the paper soaks it up very well and that it would be easier to sand high areas down.

i reinforced the helmet by adding smooth cast 320 to further reinforce the helmet. the amazing thing about this type of resin is that the paper soaks it up very well and that it would be easier to sand high areas down.